Preparation method of vanadium titanium carbide

A technology of vanadium carbide titanium and carbon powder is applied in the field of metal ceramics, which can solve the problems of high raw material cost, poor crystallinity and high energy consumption, and achieve the effects of simple process, reduced production cost and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The preparation method of vanadium-titanium carbide of the present invention can specifically be divided into three kinds, method one, comprises the steps:

[0052] a. Ingredients: mix ammonium metavanadate, titanium dioxide, and carbon powder to obtain a mixture;

[0053] Among them, ammonium metavanadate is represented by NH 4 VO 3 In terms of titanium dioxide as TiO 2 In terms, the molar ratio is NH 4 VO 3 :TiO 2 =1:9~9:1, the carbon powder is based on the C content, and the carbon content is 0.8~0.85 times of the theoretical value, that is, 1 mole of TiO 2 Need to add 2.4-2.55 moles of C, 1 mole of NH 4 VO 3 2.8-3 moles of C need to be added; the reaction formula is:

[0054] TiO 2 +3C=TiC+2CO;

[0055] 2NH 4 VO 3 =V 2 o 5 +2NH 3 +H 2 O;

[0056] V 2 o 5 +7C=2VC+5CO;

[0057] b. Press molding: the mixture is pressed and formed to obtain a briquette, and the density of the briquette is 1.5-2.5g·cm -3 ;

[0058] c. Primary carbonization: put the ...

Embodiment 1

[0101] Embodiment 1 Adopt the method of the present invention to produce high-purity vanadium titanium carbide

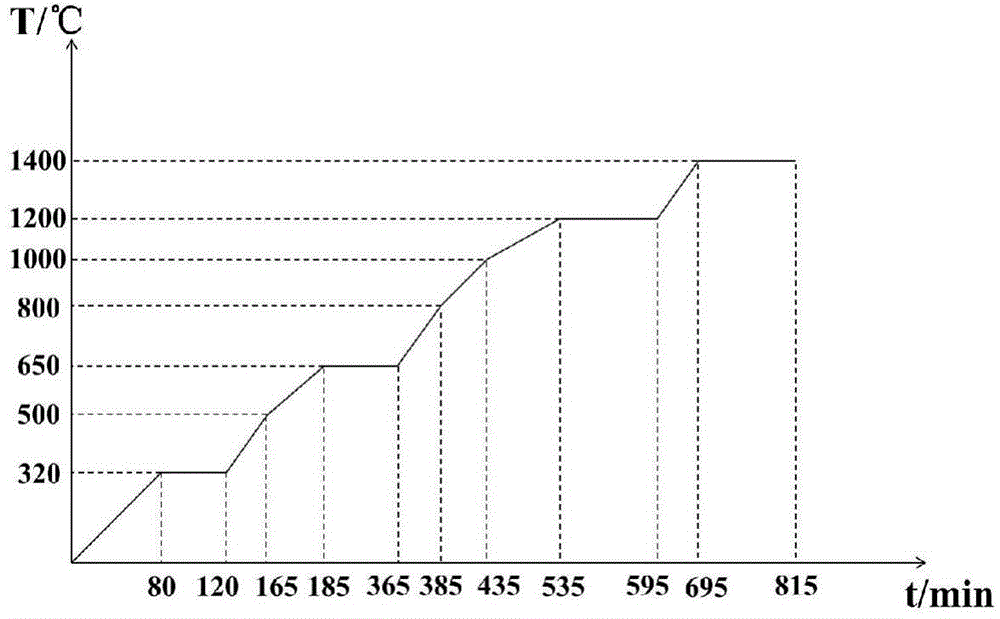

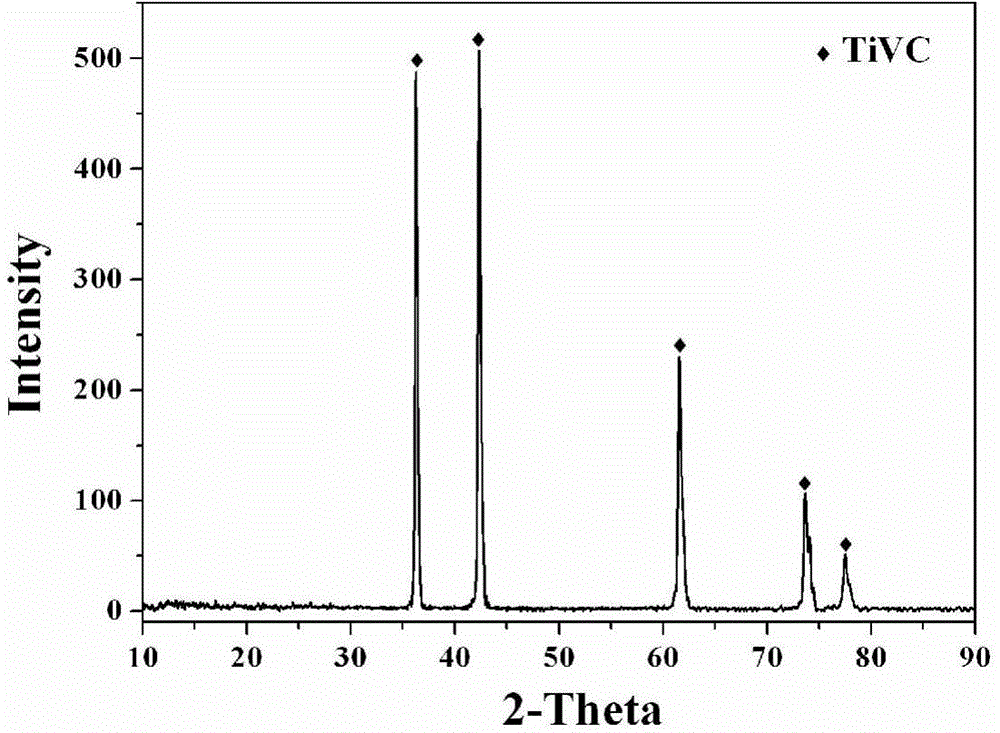

[0102] Take ammonium metavanadate (NH 4 VO 3 =99.5%, particle size≤120μm) 11.25g, titanium dioxide (TiO 2 ≥99%, particle size ≤50μm) 7.5g, graphite powder (C≥99.85%, particle size≤30μm) 6.25g, mixed and pressed to a density of 2.18g cm -3 of briquetting. Put the briquette into a 50ml aluminum oxide porcelain crucible, fill the remaining space in the porcelain crucible with 9.0g of high-purity carbon powder, and cover the top of the briquette with 9mm of carbon black. Then put the porcelain crucible into a large silicon carbide crucible with a diameter of 160 mm and a depth of 120 mm, and cover it with coal powder. Put the loaded crucible into the muffle furnace for a carbonization (schematic diagram as shown in Fig. Figure 5 shown), at 650°C for 3h, then at 922°C for 122min. After the heat preservation is over, the sample is taken out with the furnace cooling...

Embodiment 2

[0103] Embodiment 2 Adopt the method of the present invention to produce high-purity vanadium titanium carbide

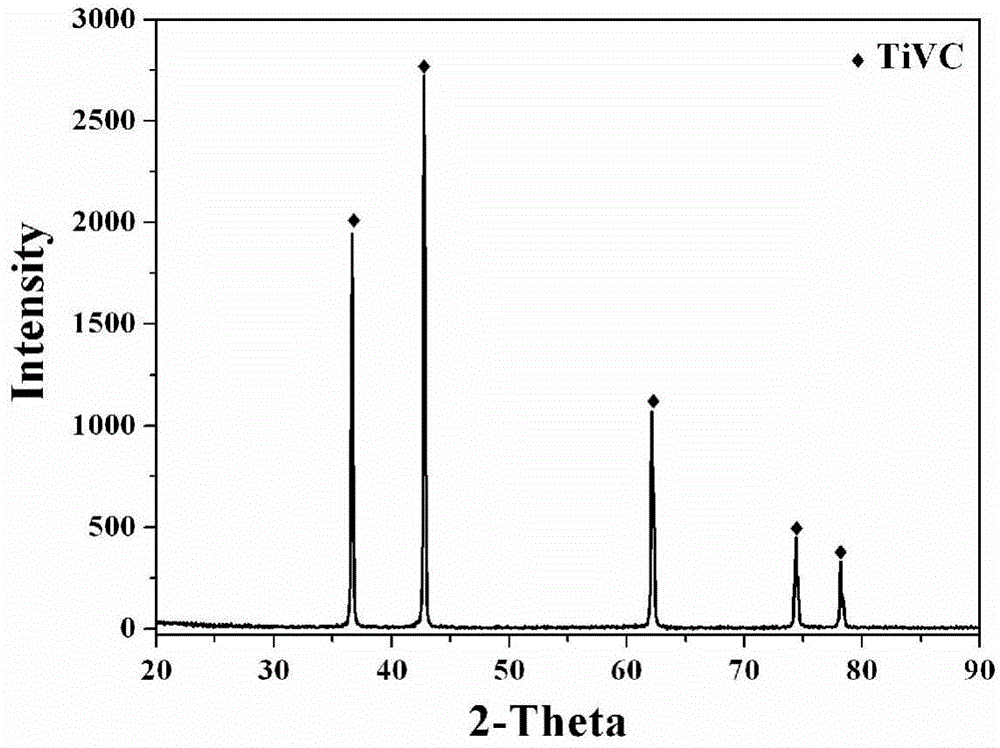

[0104] Take ammonium metavanadate (NH 4 VO 3 =99.5%, particle size≤120μm) 45.68g, titanium dioxide (TiO 2 ≥99%, particle size ≤50μm) 30.52g, graphite powder (C≥99.85%, particle size≤30μm) 23.8g, mixed and pressed to a density of 2.15g cm -3 of briquetting. Put the briquette into a 500ml aluminum oxide porcelain crucible, fill the remaining space in the porcelain crucible with 100g of high-purity carbon powder, and cover the top of the briquette with 10mm of carbon black. Then put the porcelain crucible into a large silicon carbide crucible with a diameter of 160 mm and a depth of 120 mm, and cover it with coal powder. Put the loaded crucible into the muffle furnace for a carbonization (schematic diagram as shown in Fig. Figure 5 shown), at 650°C for 3h, then at 922°C for 122min. After the heat preservation is over, cool the sample to room temperature with the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com