Method of producing oil-dosage-form aluminium powder pigment by utilization of inorganic membrane filtration and device for the method

A production device and inorganic membrane technology, applied in fibrous filler, dyeing low molecular organic compound treatment, dyeing physical treatment, etc. consumption, increased recovery costs, and shortened process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

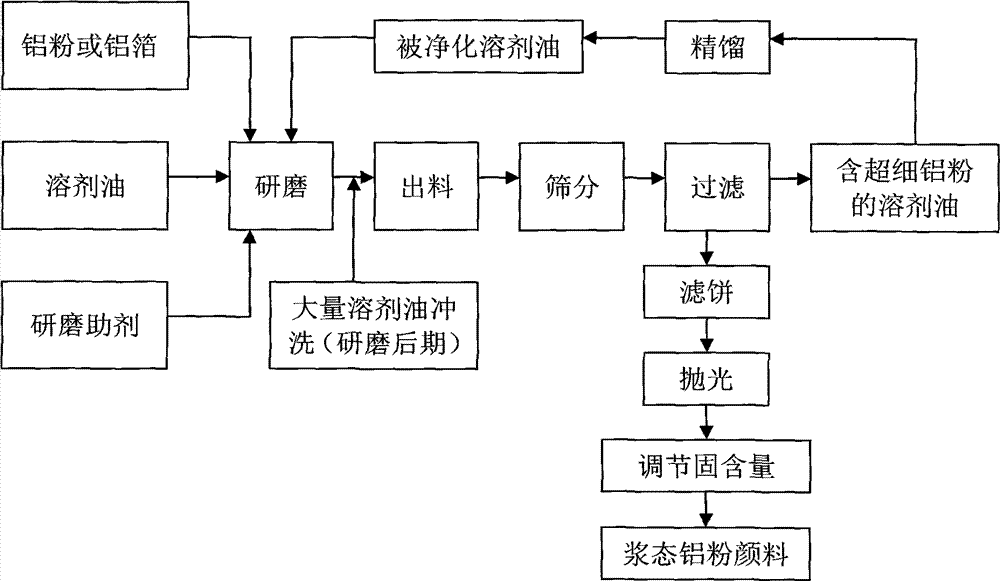

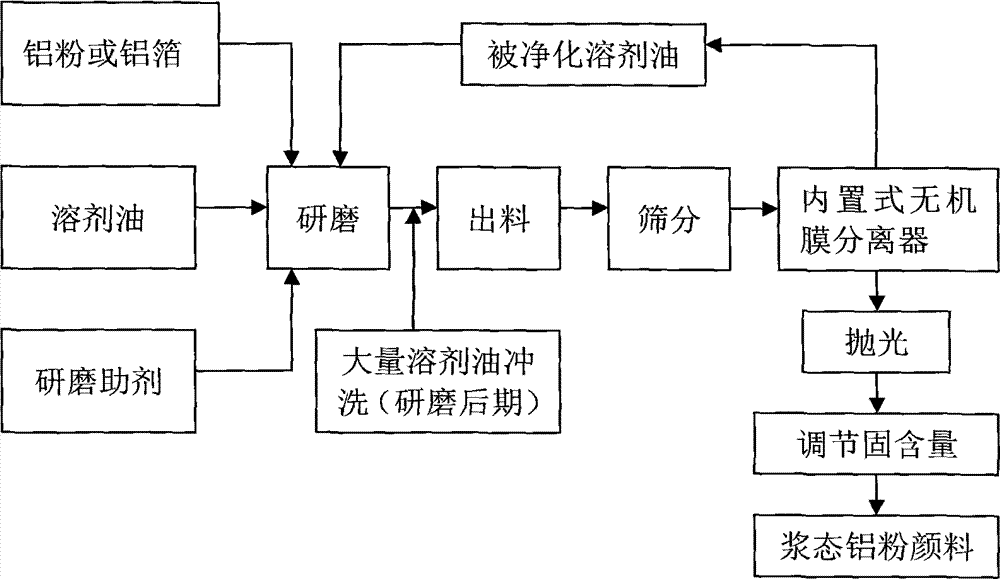

Problems solved by technology

Method used

Image

Examples

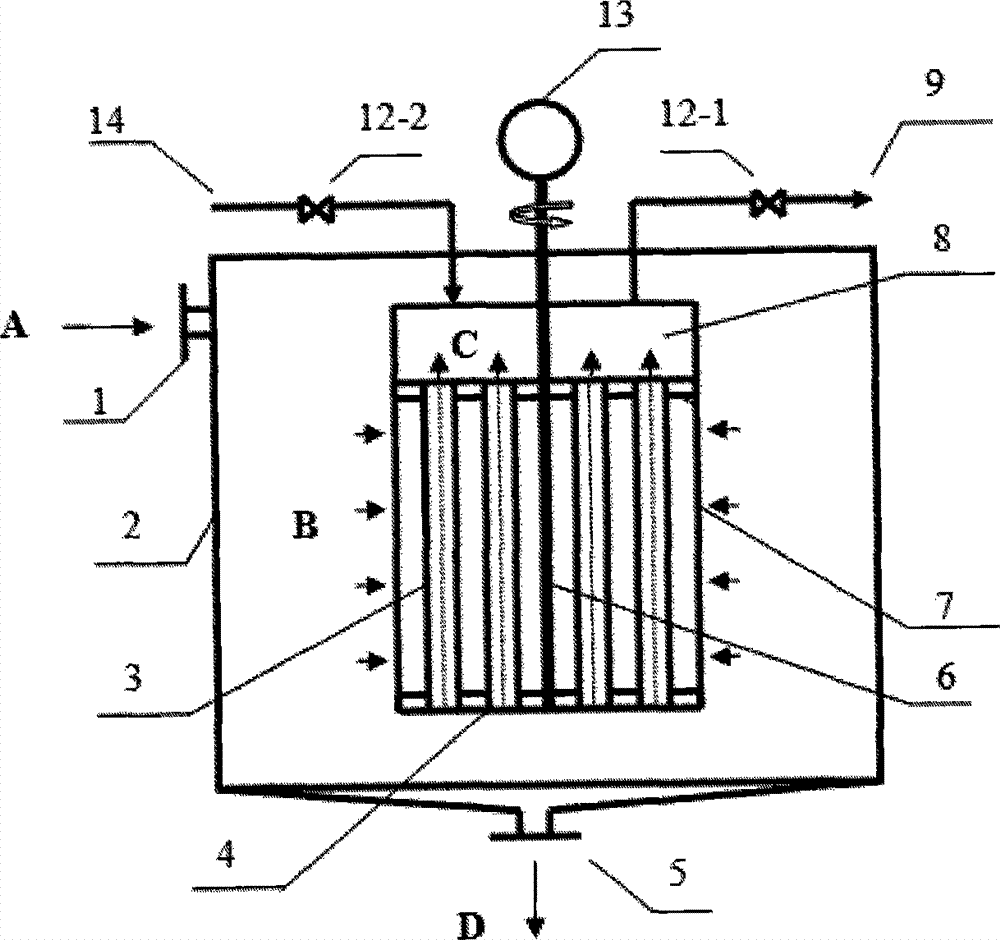

Embodiment 1

[0040] The raw material is atomized aluminum powder, the solvent oil is No. 200 solvent gasoline, the grinding aids are stearic acid, oleic acid and linolenic acid, and the grinding medium is steel balls. After sieving, the slurry aluminum powder pigment enters the built-in inorganic membrane separator for processing, using a ceramic membrane with a pore size of 800nm, 19 channels, the inner diameter of the channel is 6mm, the membrane material is aluminum oxide, and the rotation speed of the filter cartridge is 60rpm, the vacuum degree of negative pressure suction is 8×10 2 Pa, the membrane flux is 0.4m 3 m -2 h -1 , the experiment was carried out for 5 hours without backflushing the inorganic membrane filter tube, the purified solvent oil was clear and transparent, SS was not detected, the purified solvent oil fully met the requirements of returning to the grinder for continued use, and there was no loss of ultra-fine aluminum powder. After polishing the paste-state alumi...

Embodiment 2

[0042] The raw material is aluminum foil, the solvent oil is kerosene, the grinding aids are oleic acid, palmitic acid and linolenic acid, and the grinding medium is steel balls. After sieving, the slurry aluminum powder pigment enters the built-in inorganic membrane separator for processing, using a ceramic membrane with a pore size of 500nm, 7 channels, and the inner diameter of the channel is 4mm. The material of the membrane is aluminum oxide, and the rotation speed of the filter cartridge is 50rpm. The vacuum degree of negative pressure suction is 1.2×10 3 Pa, membrane permeation flux is 0.3m 3 m -2 h -1 , the experiment was carried out for 6 hours without backflushing the membrane, the purified solvent oil was clear and transparent, SS was not detected, the purified solvent oil fully met the requirements of returning to the grinder for continued use, and there was no loss of ultra-fine aluminum powder. Polish the paste-state aluminum powder pigment after desolvent oil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com