A nano-ferromagnetic mine hoist brake shoe formula and its manufacturing method

A mine hoist, nano-magnetic technology, applied in mechanical equipment, slack adjusters, friction linings, etc., can solve the problems that the magnetic field control does not have material conditions and technical basis in the braking friction process, and achieve braking efficiency and reliability. Improved heat resistance, good heat resistance, effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 8 parts of nitrile modified phenolic resin, 3 parts of nitrile rubber; 10 parts of glass fiber, 7 parts of FKF fiber, 15 parts of sepiolite fiber, 3 parts of aramid fiber; 2 parts of graphite, 6 parts of wollastonite, feldspar powder 8 parts, 5 parts of zeolite, 12 parts of barium sulfate; 2 parts of friction powder, 15 parts of carbon-coated iron nano-magnetic particles (25nm-55nm), 2 parts of silane coupling agent, and 2 parts of release agent.

Embodiment 2

[0043] 12 parts of nitrile modified phenolic resin, 3 parts of nitrile rubber; 15 parts of glass fiber, 8 parts of FKF fiber, 8 parts of sepiolite fiber, 4 parts of aramid fiber; 3 parts of graphite, 10 parts of wollastonite, feldspar powder 8 parts, 6 parts of zeolite, 9 parts of barium sulfate; 3 parts of friction powder, 8 parts of carbon-coated nickel-zinc ferrite nano-magnetic particles (30nm-50nm), 1 part of silane coupling agent, and 2 parts of release agent.

Embodiment 3

[0045] 15 parts of nitrile modified phenolic resin, 3 parts of nitrile rubber; 10 parts of glass fiber, 13 parts of FKF fiber, 8 parts of sepiolite fiber, 3 parts of aramid fiber; 4 parts of graphite, 12 parts of wollastonite, feldspar powder 8 parts, 5 parts of zeolite, 9 parts of barium sulfate; 2 parts of friction powder, 5 parts of carbon-coated nickel nano-magnetic particles (30nm-60nm), 1 part of silane coupling agent, and 2 parts of release agent.

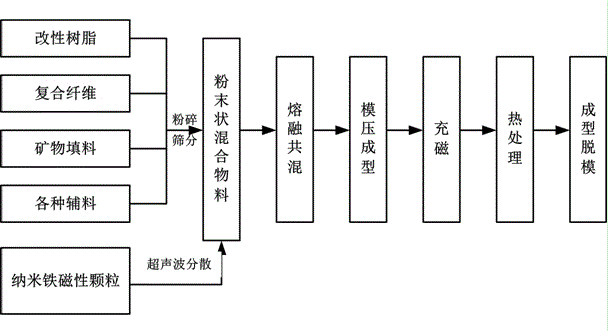

[0046] Such as figure 1 Shown: The production method of the nano-ferromagnetic mine hoist brake shoe, all raw materials are dried in a drying box at a temperature of 30°C for 6 hours; the fiber materials are made into short fibers; the block materials are processed by a pulverizer , crushed into fine powder; put the material into the mixer for high-speed mixing for 20-30 minutes; ultrasonically disperse the nano-ferromagnetic particles for 30-50 min; add the nano-ferromagnetic particles after ultrasonic dispersion to the pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com