A kind of heat-dissipating coating for LED lamp and preparation method thereof

A heat-dissipating coating and LED lamp technology, which is applied in the coating and other directions, can solve the problems of high-power LED radiators such as large volume, heavy weight, and increased heat dissipation load of the radiator, and achieve excellent mechanical properties and protection functions, and good acid and alkali resistance Sexuality and mechanical properties, and the effect of reducing the tendency of shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

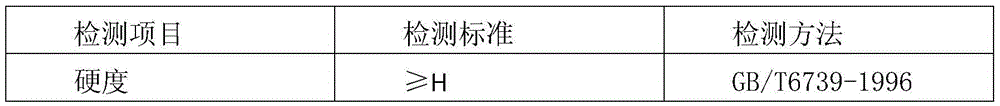

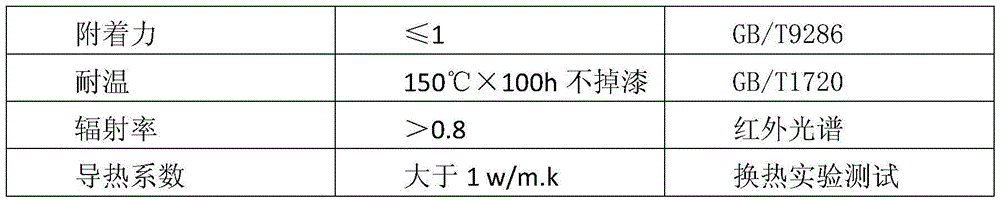

Image

Examples

Embodiment 1

[0037] Raw materials: 30g of acrylic resin with a hydroxyl value of 3 and a solid content of 50% in terms of mass percentage; 20g of urea-formaldehyde resin (ie amino resin) with a solid content of 60% in terms of mass percentage; Aluminum powder 10g; particle size 300 mesh carbon fiber powder 5g; particle size 30-40μm graphite 5g; particle size 30μm mica 10g; particle size 3-5μm fumed silica 1g; diacetone alcohol solution 9g; butyl ester solution 7.5 g; BYK-110 dispersant 2g and BYK-310 leveling agent 0.5g.

[0038] Mix the above components together thoroughly, add the amino resin at the end, disperse while adding, then add 120g of 65 grinding zirconium beads with a particle size of 0.5mm, and grind at a speed of 1300 rpm with a multi-purpose grinding and dispersing machine. Measuring its fineness to 30 μm, stop grinding, and filter with a 300-mesh sieve to obtain the target coating;

[0039] After preparation, adjust the viscosity of the prepared coating to 14s with butyl e...

Embodiment 2

[0043] Raw materials: 40g of acrylic resin with a hydroxyl value of 5 and a solid content of 40% in terms of mass percentage; 10g of urea-formaldehyde resin (ie amino resin) with a solid content of 50% in terms of mass percentage; Aluminum powder 8g; particle size 300 mesh carbon fiber powder 10g; particle size 30-40μm graphite 5g; particle size 30μm mica 8g; particle size 3-5μm fumed silica 1g; diacetone alcohol solution 8.5g; butyl ester solution 7g; BYK-110 dispersant 1g and BYK-310 leveling agent 1.5g.

[0044] Mix the above components together thoroughly, add the amino resin at the end, disperse while adding, then add 120g of 65 grinding zirconium beads with a particle size of 0.5mm, and grind at a speed of 1300 rpm with a multi-purpose grinding and dispersing machine. Measuring its fineness to 30 μm, stop grinding, and filter with a 300-mesh sieve to obtain the target coating;

[0045] After preparation, adjust the viscosity of the prepared coating to 13s with butyl ester...

Embodiment 3

[0049] Raw materials: 45g of acrylic resin with a hydroxyl value of 2.0% by mass and a solid content of 45%; 10g of urea-formaldehyde resin (i.e. amino resin) with a solid content of 55% by mass percent; particle size 3-5 μm 5g of aluminum nitride powder; 12g of carbon fiber powder with a particle size of 300 mesh; 4g of graphite with a particle size of 30-40μm; 5g of mica with a particle size of 30μm; 1g of fumed silica with a particle size of 3-5μm; 6.5g of ester solution; 1.5g of BYK-110 dispersant and 1g of BYK-310 leveling agent.

[0050] Mix the above components together thoroughly, add the amino resin at the end, disperse while adding, then add 120g of 65 grinding zirconium beads with a particle size of 0.5mm, and grind at a speed of 1300 rpm with a multi-purpose grinding and dispersing machine. Measuring its fineness to 30 μm, stop grinding, and filter with a 300-mesh sieve to obtain the target coating;

[0051] After preparation, adjust the viscosity of the prepared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com