Porous carbon electrode material based on chitosan and derivative of chitosan thereof as well as preparation method and application of porous carbon electrode material

A porous carbon electrode and chitosan technology, applied in battery electrodes, hybrid capacitor electrodes, circuits, etc., can solve the problems of restricting the application of porous carbon materials, inability to optimize the combination, and high production costs, and achieve good rate performance. Undemanding, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

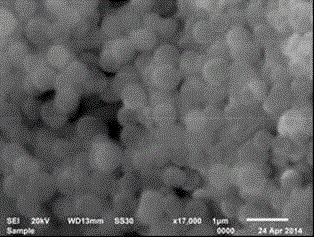

[0036] Weigh 0.35g cetyltrimethylammonium bromide (CTAB) and add it to a mixed solution of 110ml deionized water and 60ml ethanol, stir well and then add 2ml tetraethyl orthosilicate (TEOS) and 2ml ammonia water (NH 3 ·H 2 O, NH 3 Content is 25~28%), and continue to stir for 10 hours to obtain hollow silica balls; another 4g viscosity-average molecular weight is 6×10 5 Chitosan was dissolved in 200ml volume ratio of 2% glacial acetic acid solution, and after stirring for 10 hours, chitosan carbon precursor solution was obtained; then hollow silica balls were immersed in the chitosan solution, and stirred for 18 hours Pour it into a petri dish and put it in a drying oven to solidify at 100°C for 18 hours to obtain a solid film; then grind the solid film and place it in an atmosphere tube furnace to calcinate at 800°C for 3 hours under the protection of high-purity nitrogen to obtain a black solid powder; finally, the hollow silica balls were removed by hydrofluoric acid solut...

Embodiment 2

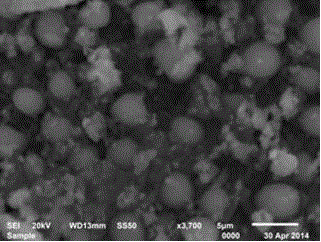

[0040] The method of this embodiment is basically the same as that of Example 1, except that in the preparation process, 4g of viscosity-average molecular weight was weighed to be 5×10 4 Chitosan was dissolved in 200ml volume ratio of 2% benzoic acid aqueous solution to prepare chitosan carbon precursor solution. The testing and characterization means are also the same as in Example 1. looks like image 3 As shown, the porous carbon and nitrogen doping content is 3.2%; the electrochemical test results are as follows Figure 6 Shown, the molecular weight is 5×10 4 When chitosan is used as the carbon precursor to prepare porous carbon, the specific capacity of the material is 582mAh / g, which is also higher than that of commercial graphite, and the Coulombic efficiency is also above 96%, which also shows good rate performance.

Embodiment 3

[0042] The method of the present embodiment is basically the same as that of Example 1, except that in the preparation process, 4 g of water-soluble carboxymethyl chitosan was dissolved in 200 ml of deionized water to prepare the chitosan carbon precursor solution. The testing and characterization means are also the same as in Example 1. looks like Figure 4 As shown, the porous carbon and nitrogen doping content is 5.6%; the electrochemical test results are as follows Figure 7 As shown, when the porous carbon is prepared with water-soluble carboxymethyl chitosan as the carbon precursor, the specific capacity of the material is 635mAh / g, which is also higher than that of commercial graphite, and the Coulombic efficiency is also above 96%. Good rate performance.

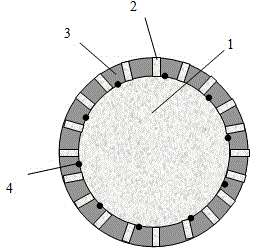

[0043] The obtained porous carbon material structure of the present invention is as figure 1 As shown, it is characterized by nitrogen doping and pore classification, and the pore structure is a hierarchical pore ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com