Novel biodegradable synthetic paper

A biodegradable and synthetic paper technology, applied in the field of polymer materials, to achieve the effect of not easy to be embrittled and broken, good ductility and toughness, and avoid environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

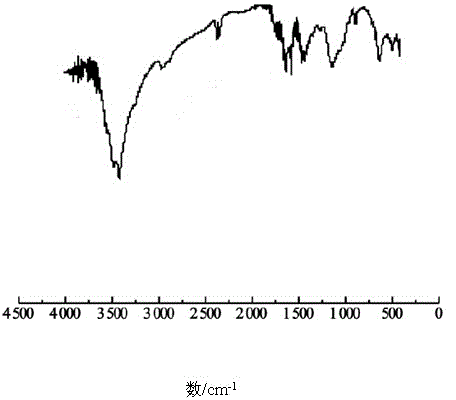

[0045] Embodiment 1 The preparation of potato starch-chitosan hydrochloride-acrylamide-allylamine hydrochloride resin

[0046] Weigh 3kg of chitosan, add 5L of hydrochloric acid with a concentration of 0.3mol / L, stir until completely dissolved, add 500g of dicyandiamide, stir at 100°C for 3h until complete reaction, and perform vacuum filtration after cooling. The filtrate is precipitated with absolute ethanol, filtered with suction, and the filter cake is washed with absolute ethanol, followed by vacuum drying to obtain chitosan hydrochloride, 500g of potato starch and distilled water are mixed together and carried out at 80°C. Cool down to room temperature after gelatinization for 1 hour, then add 2kg of chitosan hydrochloride prepared in the first step, 500g of allylamine hydrochloride and acrylamide aqueous solution and mix together, the usage of acrylamide is 4kg, add initiator 60g of ammonium persulfate and 25g of glycerin were stirred evenly and then placed in an oven a...

Embodiment 2

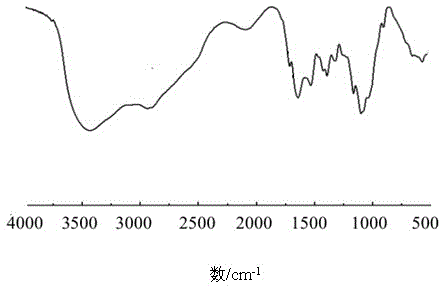

[0047] The preparation of embodiment 2 acrylic acid-chitooligosaccharide

[0048] 1kg chitosan oligosaccharide, 1-ethyl-3-(3-dimethylaminopropyl) carbodiimide hydrochloride 600g, N-hydroxysuccinimide 300g were dissolved in 3L of dilute hydrochloric acid with a pH value of 4.7, After stirring until completely dissolved, 500 g of acrylic acid was added, and the reaction was carried out under magnetic stirring at room temperature for 72 h. After the reaction was completed, the reaction product was slowly poured into 150 mL of absolute ethanol, stirred to fully precipitate the chitosan derivative, vacuum filtered, and the filter cake was taken to dry naturally to obtain the product. The infrared spectrum of the product was as follows: figure 2 shown.

Embodiment 3

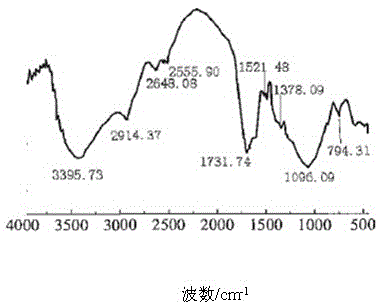

[0049] Example 3 Preparation of mercapto lignin

[0050] Add 1kg of mercaptoacetic acid, 0.35kg of acetic anhydride, 1L of 36% acetic acid and 300g of concentrated sulfuric acid into the reaction vessel in sequence, stir well, then add 2kg of lignin dry sample, stir, mix evenly, and then put it in an oven at 40°C for 2 days. Take out, suction filter, after fully washing with distilled water, dry under reduced pressure at normal temperature, obtain product, the infrared spectrogram of product is as follows: image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com