Preparation method of fluorescence-enhanced rear-earth metal oxide nanosheet sol with positive charges

A technology with positive charges and rare earth metals, applied in the fields of rare earth metal compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of easy dehydration structure of hydroxide nanosheets, poor thermal stability, and reduced luminescence performance of rare earth hydroxide materials and other issues, to achieve good application prospects, good luminous performance, and save preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

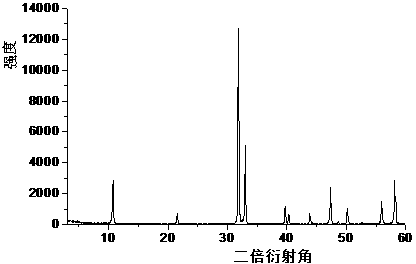

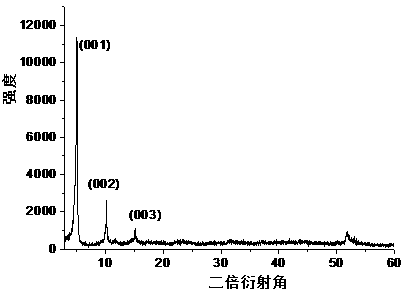

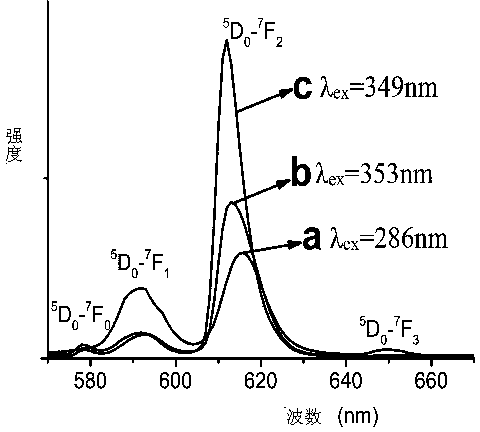

Image

Examples

Embodiment 1

[0021] a. Take 2.0005gY 2 o 3 and 0.1641gEu 2 o 3 , dissolved in 150ml of 0.5mol / L nitric acid solution to obtain a transparent solution, then added 35ml of 1mol / L oxalic acid solution to obtain an oxalate precipitate, and calcined the oxalate precipitate at 720°C for 2 hours to obtain Y 1.9 Eu 0.1 o 3 . Take 1.0529gY 1.9 Eu 0.1 o 3 , add 1.7770gNH 4 Br, and then grind the two in a mortar and mix well.

[0022] b. Transfer the mixture obtained in the above steps into a crucible, shake it tightly and put it into a muffle furnace. The heating condition is 420°C for 2 hours, then heat up to 700°C for 2 hours, after cooling to room temperature, take out the sample and use the pre-prepared 100ml concentration of 1×10 -4 mol / L acetic acid solution, 200ml distilled water to wash the sample, then suction filter and dry to obtain pure Y 0.95 Eu 0.05 OBr.

[0023] c. Take the Y obtained in the previous step of 1.0000g 0.95 Eu 0.05 OBr, put it in 100ml of sodium benzoate...

Embodiment 2

[0026] a. Take 1.0025gY 2 o 3 and 0.0822gEu 2 o 3 , dissolved in 80ml of nitric acid solution with a concentration of 0.5mol / L to obtain a transparent solution, then add 25ml of oxalic acid solution with a concentration of 1mol / L to obtain an oxalate precipitate, and calcinate the oxalate precipitate at 750°C for 2 hours, get Y 1.9 Eu 0.1 o 3 . Take 0.5026gY 1.9 Eu 0.1 o 3 , adding 1.0602gNH 4 Br, and then grind the two in a mortar and mix well.

[0027] b. Transfer the mixture obtained in the above steps into a crucible, shake it tightly and put it into a muffle furnace. The heating condition is 450°C for 2 hours, then heat up to 680°C for 2 hours, after cooling to room temperature, take out the sample and use the pre-prepared 80ml concentration of 1×10 -4 mol / L acetic acid solution, 120ml distilled water to wash the sample, then suction filter and dry to obtain pure Y 0.95 Eu 0.05 OBr.

[0028] c. Take 1.5000g of Y obtained in the previous step 0.95 Eu 0.05 ...

Embodiment 3

[0031] a. Take 3.5000gY 2 o 3 and 0.2985gTb 2 o 3 , dissolved in 220ml of nitric acid solution with a concentration of 0.5mol / L to obtain a transparent solution, then add 60ml of oxalic acid solution with a concentration of 1mol / L to obtain an oxalate precipitate, and calcinate the oxalate precipitate at 750°C for 3 hours, get Y 1.9 Tb 0.1 o 3 . Take 2.5890gY 1.9 Tb 0.1 o 3 , adding 10.8912gNH 4 Br, and then grind the two in a mortar and mix well.

[0032] b. Transfer the mixture obtained in the above steps into a crucible, shake it tightly and put it into a muffle furnace. The heating condition is 400°C for 2.5 hours, then heat up to 720°C for 2 hours, after cooling to room temperature, take out the sample and use the pre-prepared 250ml concentration of 1×10 -4 mol / L acetic acid solution, 500ml distilled water to wash the sample, then suction filter and dry to obtain pure Y 0.95 Tb 0.05 OBr.

[0033] c. Take 2.0000g of Y obtained in the previous step 0.95 Tb ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com