Hydrogen-passivated zinc oxide-base thin film transistor and preparation method thereof

A thin-film transistor and zinc oxide thin-film technology, which is applied in the direction of transistors, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve the problems of poor thermal stability and easy deterioration of device electrical performance, and achieve small hysteresis effect and increase load capacity. Good effect on carrier concentration and electrical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

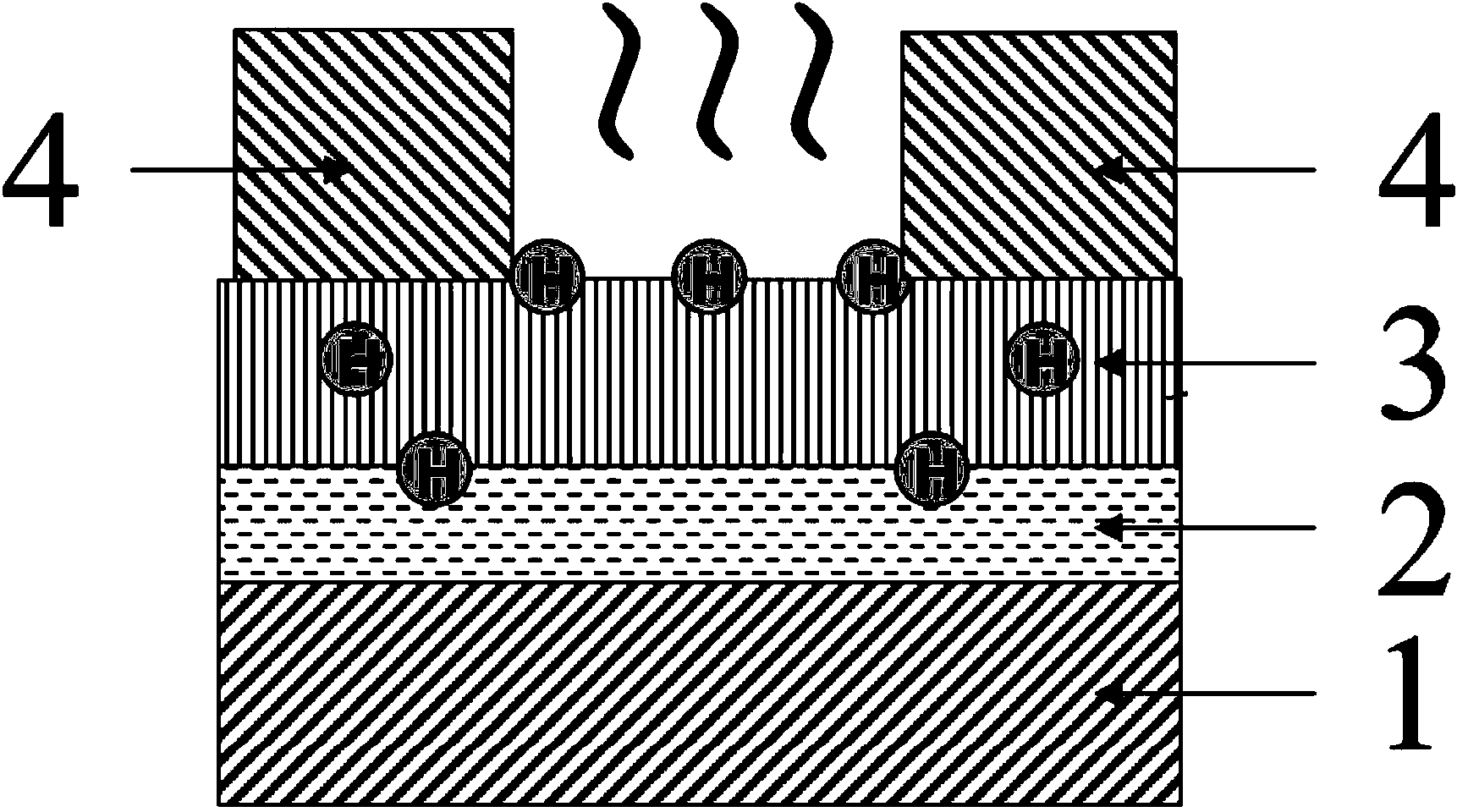

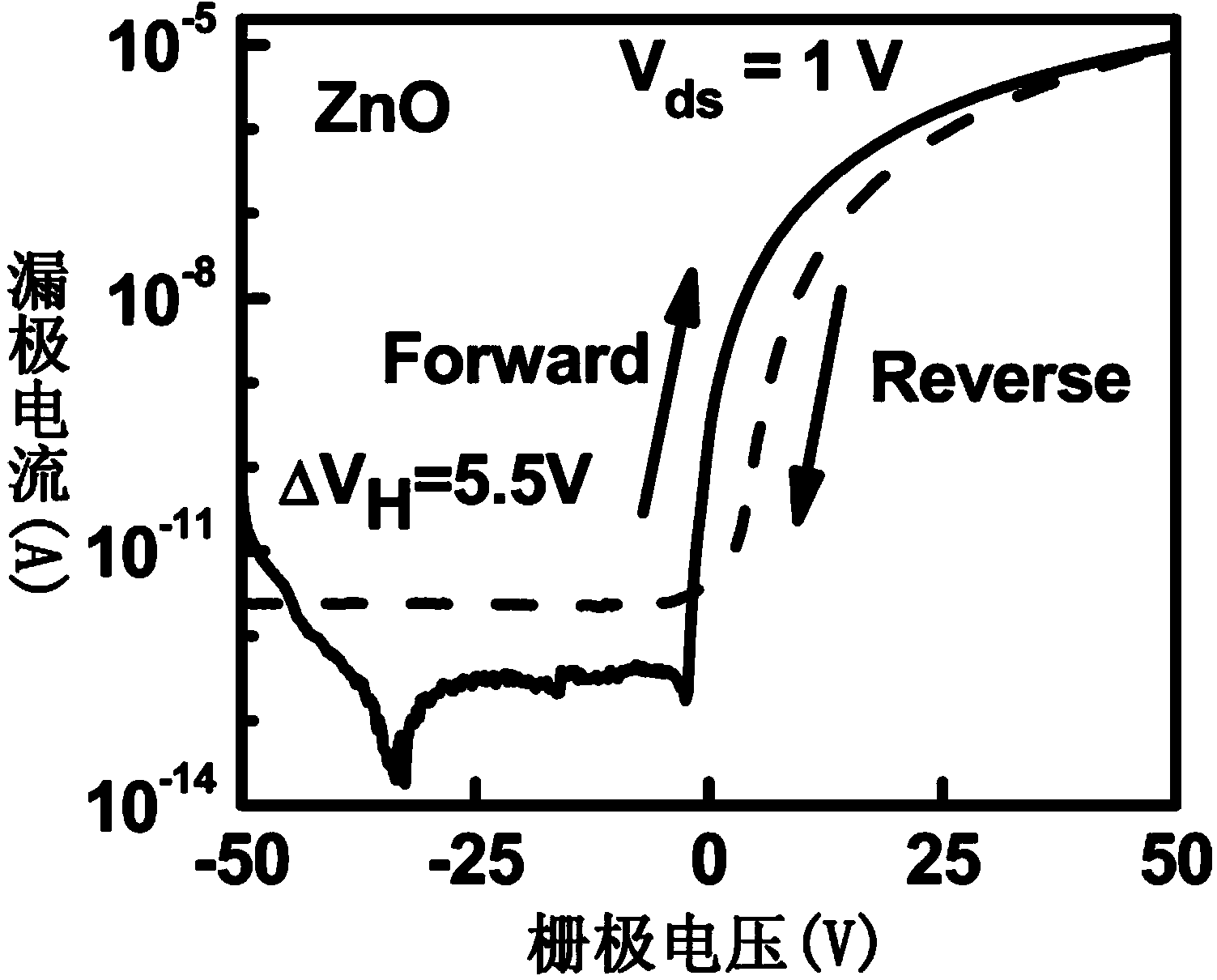

[0039] (1) Silicon wafers grown with 100nm thick silicon dioxide are used as substrates after being ultrasonically cleaned with acetone, isopropanol, deionized water, etc. and blown dry with nitrogen. Under the sputtering carrier gas of argon, a high-purity zinc oxide ceramic target (99.99%) was sputtered with a low-power radio frequency magnetron sputtering of 50 watts, and was divided into small pieces with an area of 530 um × 530 um by mask deposition, and To reduce the parasitic capacitance and leakage current introduced in the transistor preparation process, the thickness of the film is controlled to be 15 nanometers by sputtering time. (2) After secondary mask deposition and low-power DC sputtering of 20 watts to form aluminum electrodes, zinc oxide thin film transistors with original electrical properties can be obtained, and their mobility is 10 cm 2 / Vs. image 3 Shown are the transfer characteristic curves of the ZnO TFT in the ranges of -50V to 50V and 50V to -50...

Embodiment 2

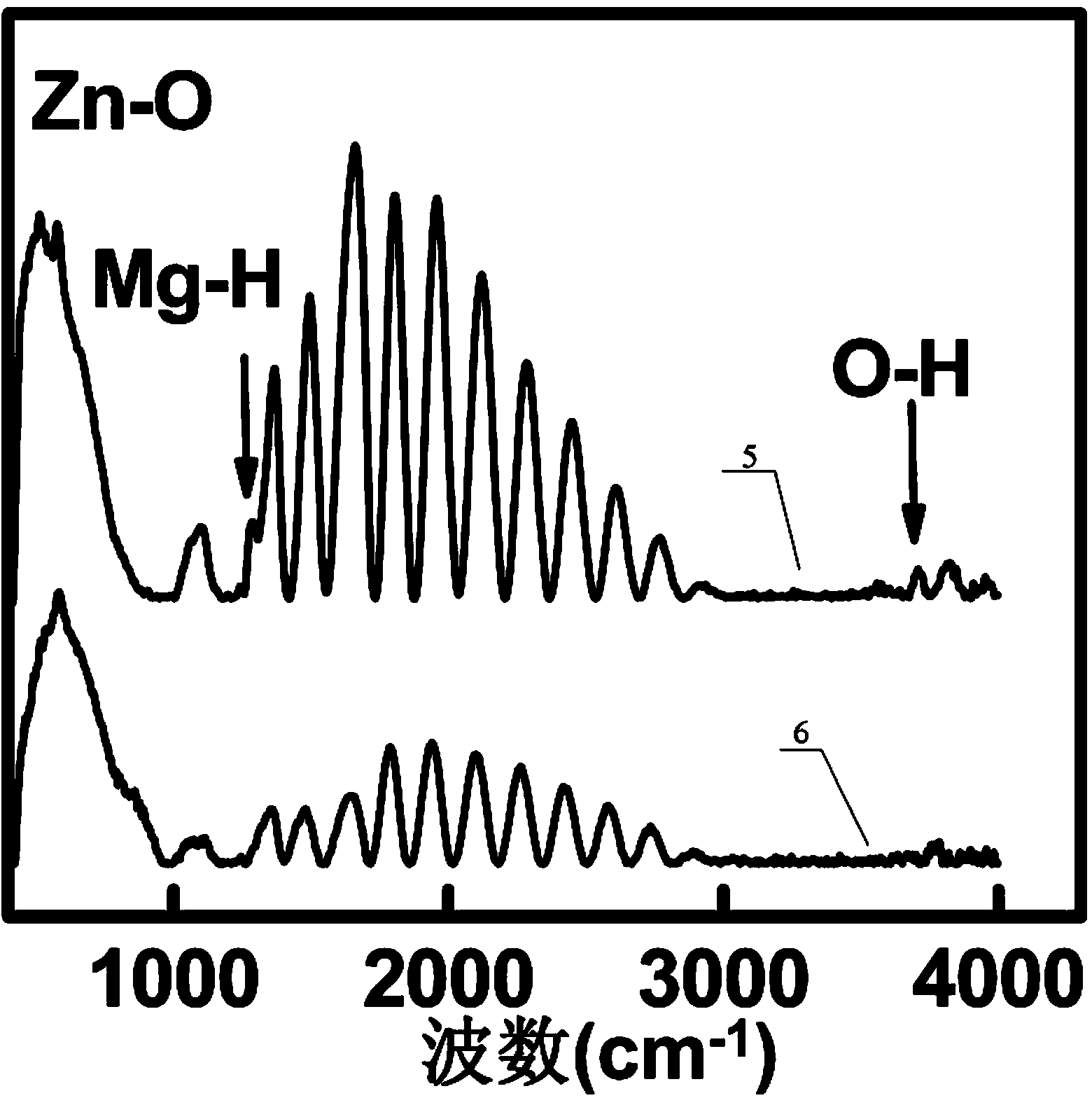

[0041](1) Silicon wafers grown with 100nm thick silicon dioxide are used as substrates after being ultrasonically cleaned with acetone, isopropanol, deionized water, etc. and blown dry with nitrogen. Under the sputtering carrier gas of argon, a high-purity zinc oxide ceramic target (99.99%) was sputtered with a low-power radio frequency magnetron sputtering of 50 watts, and was divided into small pieces with an area of 530 um × 530 um by mask deposition, and To reduce the parasitic capacitance and leakage current introduced in the transistor preparation process, the thickness of the film is controlled to be 15 nanometers by sputtering time. (2) After the sputtering is over, close the baffle, and inject a mixed gas of argon and hydrogen (hydrogen accounts for 20% of the total gas) for 30 seconds in situ for hydrogen plasma treatment. (3) After secondary mask deposition and low-power DC sputtering of 20 watts to form aluminum electrodes, a hydrogen-passivated zinc oxide thin f...

Embodiment 3

[0043] (1) Silicon wafers with a thickness of 100 nanometers of silicon dioxide are used as substrates after being ultrasonically cleaned with acetone, isopropanol, deionized water, etc. and blown dry with nitrogen. The temperature of the substrate is 150°C, and the sputtering pressure is 0.6Pa. A high-purity zinc oxide and titanium composite ceramic target (the atomic content of titanium is about 0.5%) was sputtered with a low-power radio frequency magnetron sputtering of 50 watts, and was divided into small pieces with an area of 530 um × 530 um by mask deposition to reduce the The parasitic capacitance and leakage current introduced in the preparation process of the small transistor are controlled by the sputtering time to a thickness of 15 nanometers. (2) After the sputtering is over, close the baffle, and inject a mixed gas of argon and hydrogen (hydrogen accounts for 20% of the total gas) for 30 seconds in situ for plasma treatment. (3) A low-power DC sputtering of 20 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com