Polymer solar cell device and preparation method thereof

A technology of solar cells and polymers, applied in the field of solar cells, which can solve problems such as rising device series resistance, affecting photoelectric conversion efficiency, and increasing the difficulty of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

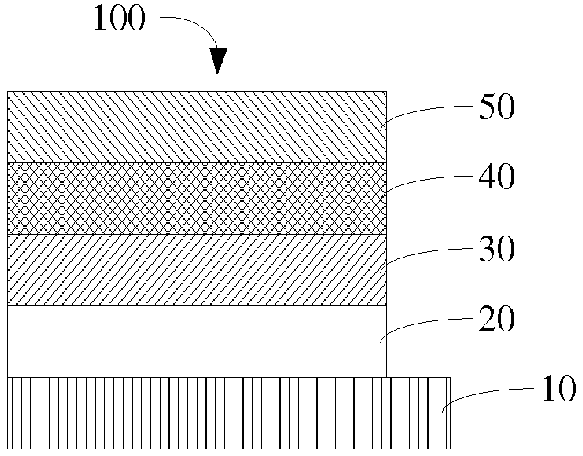

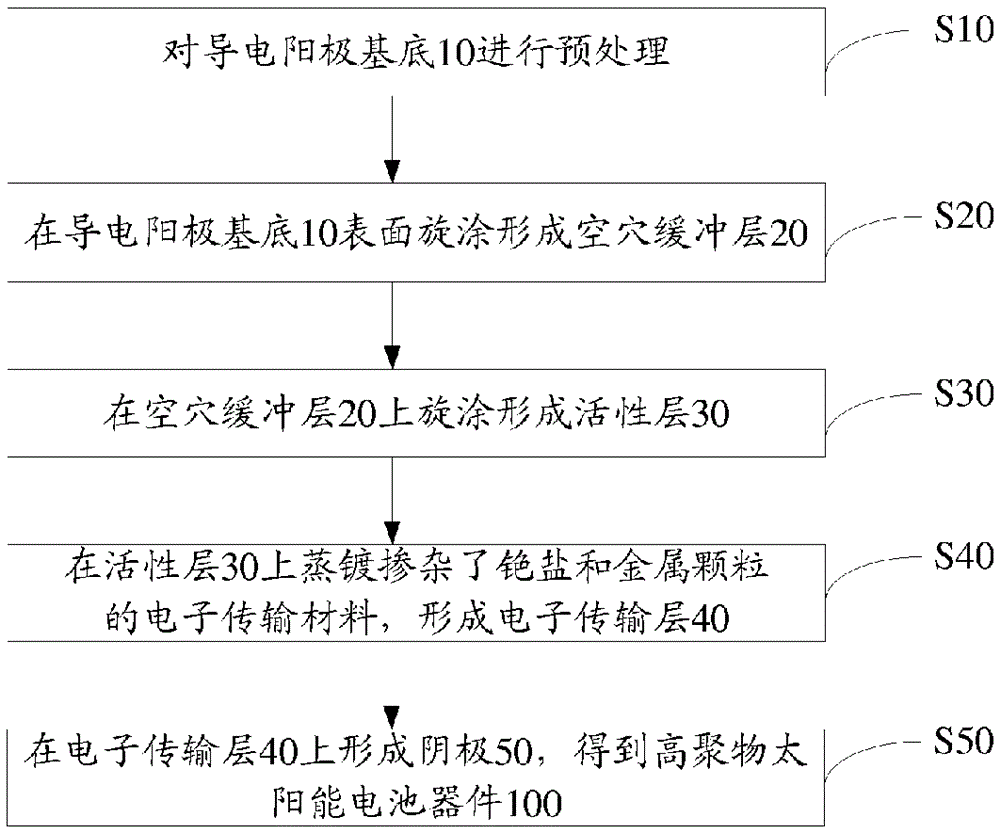

[0050] Such as figure 2 The manufacturing method of the above-mentioned polymer solar cell device 100 shown includes the following steps:

[0051] In step S10, the conductive anode substrate 10 is pretreated.

[0052] The material of the conductive anode substrate 10 may be indium tin oxide glass (ITO), fluorine-doped tin oxide glass (FTO), aluminum-doped zinc oxide glass (AZO), or indium-doped zinc oxide glass (IZO).

[0053] The pretreatment process is: cleaning the conductive anode substrate 10, and then performing oxygen plasma treatment or ozone-ultraviolet treatment on the conductive anode substrate 10.

[0054] Specifically, the conductive anode substrate 10 is first subjected to photolithography processing, cut into a required size, and then ultrasonicated with detergent, deionized water, acetone, ethanol, and isopropanol for 15 minutes to remove organic contaminants on the glass surface. After cleaning, the conductive anode substrate 10 is subjected to oxygen plasma treatmen...

Embodiment 1

[0085] The structure of the polymer solar cell device prepared in this embodiment is: ITO / (PEDOT: PSS) / (MEH-PPV: PCBM) / (Bhpen: Cs 2 CO 3 : Ag) / Al.

[0086] The preparation process of the above-mentioned polymer solar cell device is as follows:

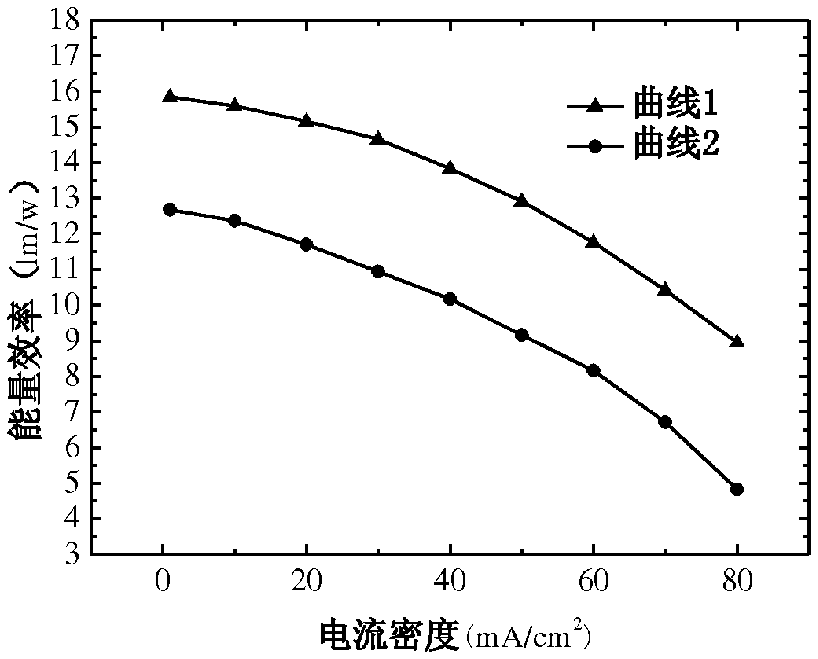

[0087] Firstly, the ITO is subjected to photolithography processing, cut into the required size, and then sonicated with detergent, deionized water, acetone, ethanol, and isopropanol for 15 minutes to remove organic contaminants on the glass surface. After cleaning, oxygen plasma treatment is carried out. The treatment time is 5min and the power is 30W. Then, an aqueous solution of PEDOT and PSS with a mass ratio of 6:1 and a mass percentage of 1.3% was spin-coated on the ITO and heated at 200° C. for 30 minutes to prepare a hole buffer layer with a thickness of 40 nm. Then, under a nitrogen atmosphere, the chlorobenzene solution of MEH-PPV and PCBM with a mass ratio of 1:3 and a total concentration of 24 mg / mL was spin-coated on the hole ...

Embodiment 2

[0096] The structure of the polymer solar cell device prepared in this embodiment is: IZO / (PEDOT: PSS) / (MDMO-PPV: PCBM) / (PBD: CsF: Al) / Ag.

[0097] The preparation process of the above-mentioned polymer solar cell device is as follows:

[0098] The IZO is first subjected to photolithography processing, cut into the required size, and then ultrasonicated with detergent, deionized water, acetone, ethanol, and isopropanol for 15 minutes to remove organic contaminants on the glass surface. After cleaning, oxygen plasma treatment is carried out. The treatment time is 5min and the power is 30W. Then, an aqueous solution of PEDOT and PSS with a mass ratio of 2:1 and a mass percentage of 5% was spin-coated on IZO and heated at 100° C. for 60 minutes to prepare a hole buffer layer with a thickness of 20 nm. Next, in an argon atmosphere, a xylene solution of MDMO-PPV and PCBM with a mass ratio of 1:4 and a total concentration of 8 mg / mL was spin-coated on the hole buffer layer, and annealed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com