Damping and denoising water-soluble damping coating for passenger vehicle and preparation method thereof

A technology of damping coatings and passenger cars, applied in coatings and other directions, can solve problems such as environmental protection, poor sound insulation performance, and increased car body weight, and achieve good shock and noise reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

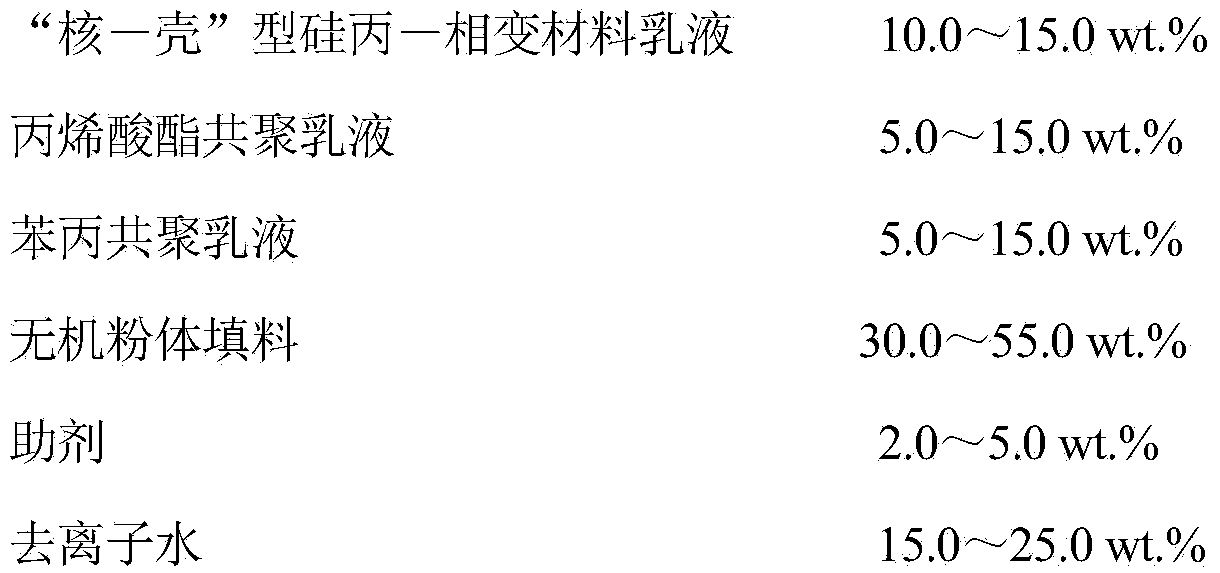

Embodiment 1

[0027] Synthesis of "core-shell" type silicon acrylic-phase change material emulsion, the process is: firstly heat 200mL deionized water to 80°C, then add 35g paraffin and 3g polyethylene oxide-polypropylene oxide-polycyclo Oxyethane block copolymer template was mixed and stirred to form a stable emulsion; in another container, 22g of sodium silicate was dissolved in 50mL of deionized water and stirred, and the pH value was adjusted to 5.5-6.5 with hydrochloric acid to form a silica sol; then Add the silica sol dropwise into the paraffin wax emulsion, adjust the pH value to 4.5-5.0 and continue to stir for 4 hours; after cooling the obtained silica-coated paraffin wax suspension to 60°C, continue to add the template agent and stir and emulsify for 30 minutes, then Add 25g of ethyl acrylate, 15g of active siloxane containing double bonds, and 1g of sodium persulfate initiator, and stir and react for 5 hours to obtain a "core-shell" silicone acrylic-phase change material emulsion...

Embodiment 2

[0031] The synthesis method of the "core-shell" silicone acrylic-phase change material emulsion is the same as that in Example 1.

[0032] The preparation process of the shock-absorbing and noise-reducing water-based damping coating for passenger cars is as follows: firstly, 150mL deionized water is added to a high-speed stirring tank, followed by adding 8g of dispersant, 7g of corrosion inhibitor, 150g of wollastonite, 150g of sericite, glass micro 150 g of beads were dispersed and stirred evenly, and then ground with a conical mill until the fineness of the dispersed phase reached below 30 μm to obtain a water-dispersed slurry. Then, under high-speed stirring, add 190g of silicon acrylic-phase change material emulsion, 190g of acrylate copolymer emulsion and 150g of styrene-acrylic copolymer emulsion into the above-mentioned water slurry, then add 5g of pH regulator, 10g of defoamer, and finally add 12g of the rheological additive, mixed and stirred evenly, and then filtered...

Embodiment 3

[0035] The synthesis method of the "core-shell" silicone acrylic-phase change material emulsion is the same as that in Example 1.

[0036] The preparation process of the shock-absorbing and noise-reducing water-based damping coating for passenger cars is as follows: first, 150 mL of deionized water is added to a high-speed stirring tank, followed by adding 10 g of dispersant, 7 g of corrosion inhibitor, 100 g of wollastonite, 250 g of sericite, and glass micro 150 g of beads were dispersed and stirred evenly, and then ground with a conical mill until the fineness of the dispersed phase reached below 30 μm to obtain a water-dispersed slurry. Then, under high-speed stirring, add 150g of silicon acrylic-phase change material emulsion, 150g of acrylate copolymer emulsion and 190g of styrene-acrylic copolymer emulsion into the above-mentioned water slurry, then add 5g of pH regulator, 10g of defoamer, and finally add 12g of the rheological additive, mixed and stirred evenly, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com