Laser cutting device for acrylic sheet cutting

An acrylic sheet, laser cutting technology, used in laser welding equipment, welding/welding/cutting items, sound-emitting equipment, etc., can solve problems such as poor shock absorption and noise reduction, and achieve stable operation, improve practicability, and reduce noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

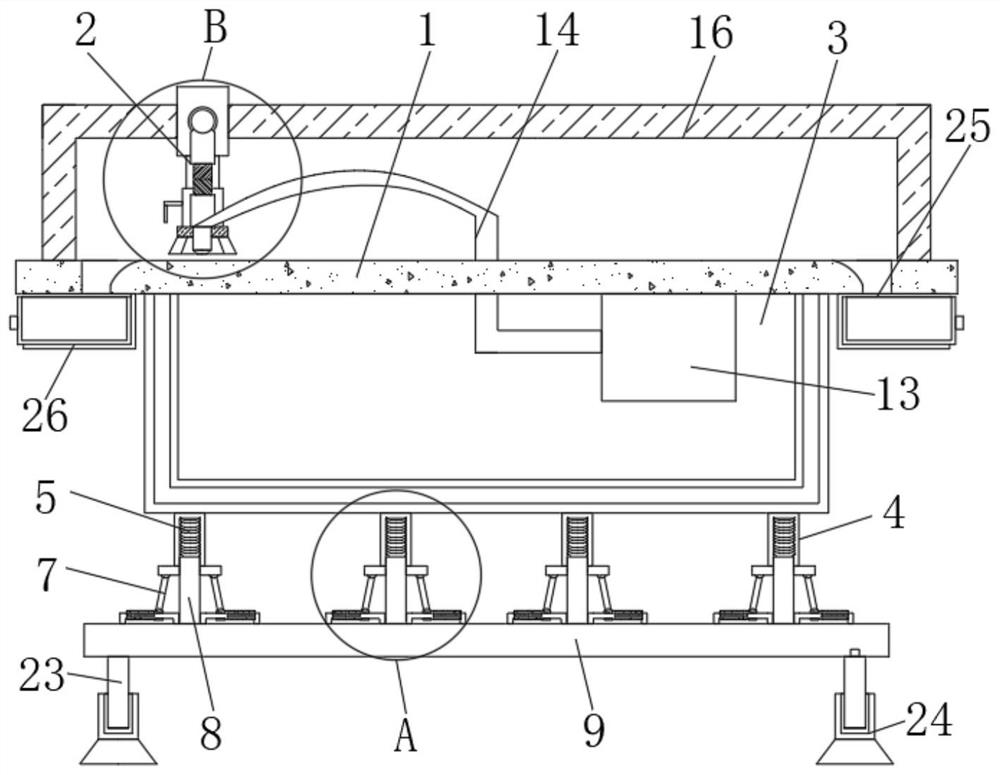

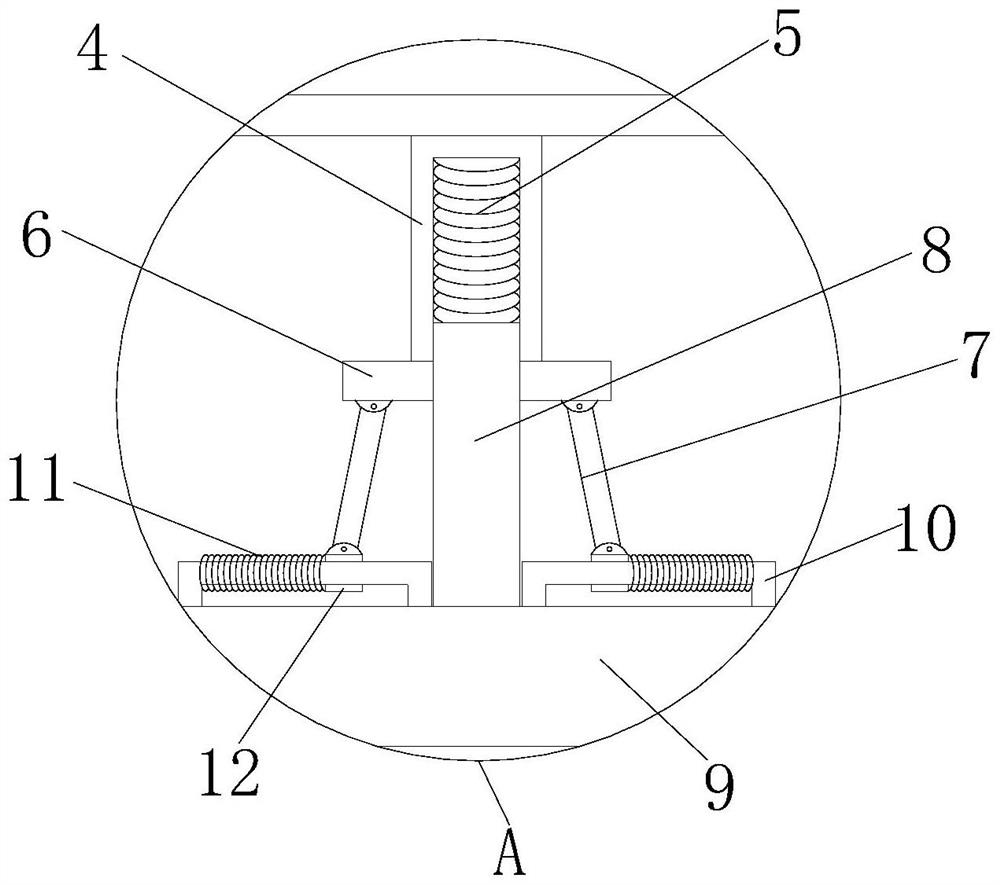

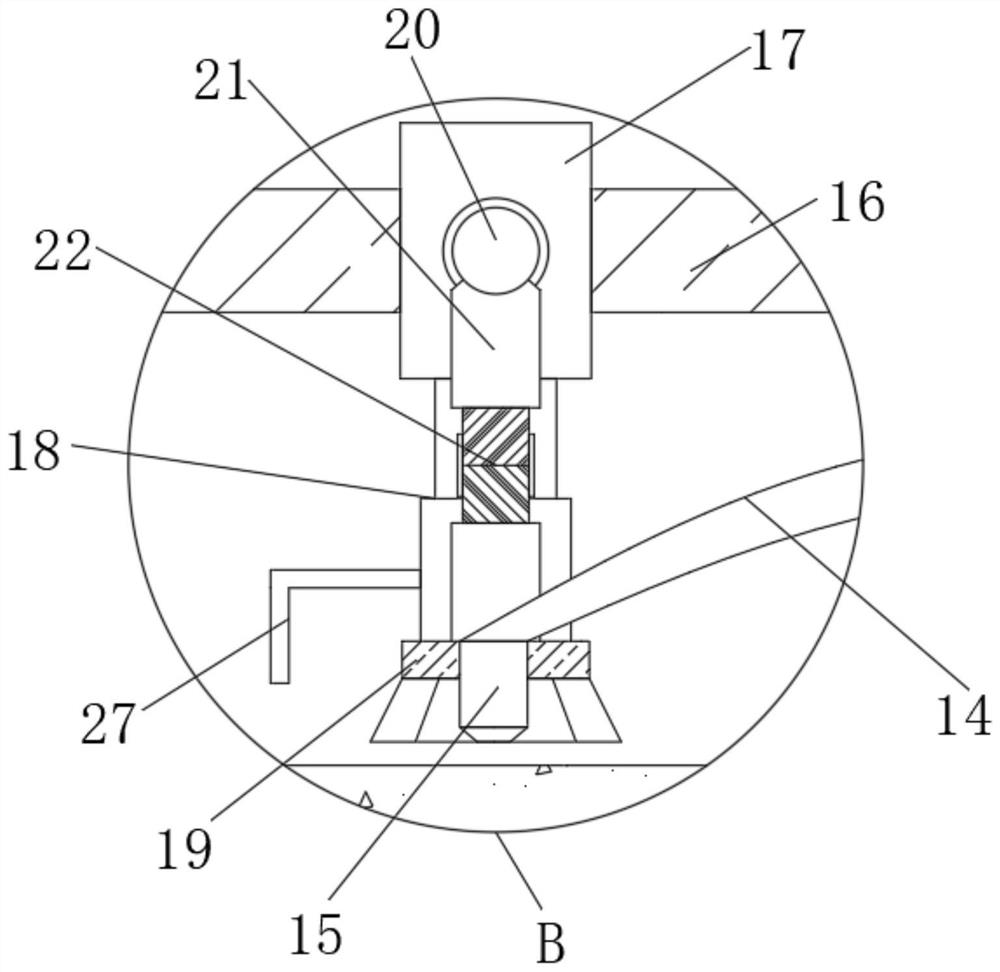

[0023] Such as Figure 1-Figure 6 As shown, the present embodiment provides a laser cutting device for cutting acrylic sheets, including a platen 1, a cleaning laser cutting assembly 2 is arranged on the platen 1, a soundproof box 3 is fixed on the bottom of the platen 1, and the soundproof box 3 The bottom is uniformly provided with a buffer tube 4, the inner top wall of the buffer tube 4 is fixed with a first spring 5, the bottom of the buffer tube 4 is fixed with a disc 6, and the bottom of the disc 6 is evenly provided with a connecting rod 7, and the connecting rod 7 The bottom ends of the slide tubes 12 are hinged, and the inside of the slide tubes 12 is slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com