Preparation method of positive electrode material of lithium iron phosphate battery

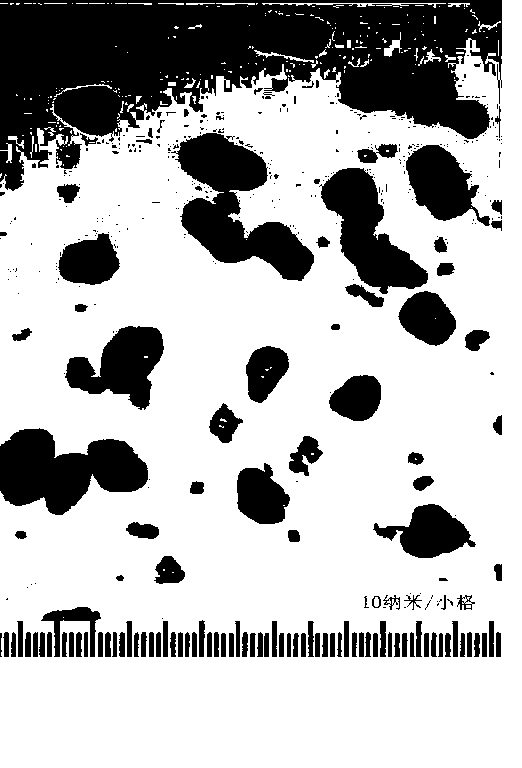

A technology for lithium iron phosphate batteries and cathode materials, applied in battery electrodes, lithium batteries, chemical instruments and methods, etc., can solve the problems of difficult control of grain growth, inability to produce continuously, long production cycle, etc., and achieve regular appearance, The effect of reduced production cycle and uniform grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) Weigh the basic raw materials lithium phosphate, ferrous oxalate, magnesium chloride, and lithium dihydrogen phosphate into the mixer according to the molar ratio Li:Fe:M:P=1:0.8:0.1:1, and then add 0.2% of the mass of the basic raw materials The esterified styrene maleic anhydride resin is used as a dispersant, and 0.6% of the mass of the basic raw material is added as a grain growth inducer nano-magnesium oxide, and 5% of the mass of the basic raw material is added. Air jet mill, which crushes and homogenizes materials through strong impact and severe friction;

[0030] 2) Send the homogenate obtained in step 1) into a reciprocating single-screw extruder, and the screw reciprocates axially during the radial rotation process, and uses the reciprocating single-screw to shear evenly, highly disperse, and pull The characteristics of stretching make the material homogeneous in the axial direction. Under the action of shearing, turning, kneading and stretching, the grain...

Embodiment 2

[0033] 1) Weigh the basic raw materials lithium hydroxide, ferrous phosphate, beryllium chloride, and ammonium dihydrogen phosphate into the mixer according to the molar ratio Li:Fe:M:P=1:0.8:0.1:1, and then add the mass of the basic raw materials 0.5% of the imidized styrene maleic anhydride resin is used as a dispersant, adding 1% of the quality of the basic raw material as a grain growth inducer nano-titanium dioxide, adding 6% of the quality of the basic raw material to powder polyethylene, and mixing evenly Send it into the flat airflow mill, and crush and homogenize the material through strong impact and severe friction;

[0034] 2) Send the homogenate obtained in step 1) into a reciprocating single-screw extruder, and the screw reciprocates axially during the radial rotation process, and uses the reciprocating single-screw to shear evenly, highly disperse, and pull The characteristics of stretching make the material homogeneous in the axial direction. Under the action o...

Embodiment 3

[0037] 1) Weigh the basic raw materials lithium nitrate, ferrous oxide, calcium chloride, and diammonium hydrogen phosphate into the mixer according to the molar ratio Li:Fe:M:P=1:0.8:0.1:1, and then add the mass of the basic raw materials 0.4% styrene maleic anhydride amic acid resin as a dispersant, add 0.6% of the mass of the basic raw material grain growth inducer nano-magnesium oxide, add 8% of the mass of the basic raw material polyvinyl chloride, mix evenly and send into Flat airflow mill, crushing and homogenizing materials through strong impact and friction;

[0038] 2) Send the homogenate obtained in step 1) into a reciprocating single-screw extruder, and the screw reciprocates axially during the radial rotation process, and uses the reciprocating single-screw to shear evenly, highly disperse, and pull The characteristics of stretching make the material homogeneous in the axial direction. Under the action of shearing, turning, kneading and stretching, the grain grows...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com