Nickel-rhenium alloy target material and preparation method thereof

A technology of rhenium alloy and target material, which is applied in the field of nickel-rhenium alloy target material and its production method, can solve the problems of large particle size variation, insufficient crystallinity, and coarse grain, so as to improve crystallinity and solve the problem of grain size. Large variation in particle size, solving the effect of coarse grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 19

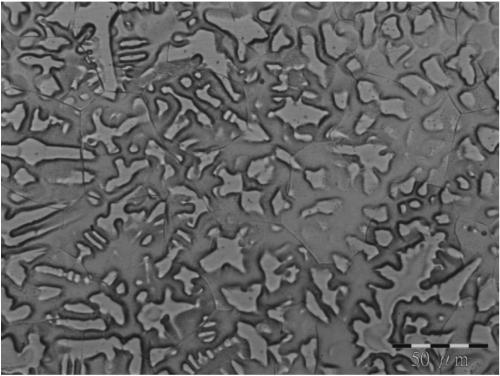

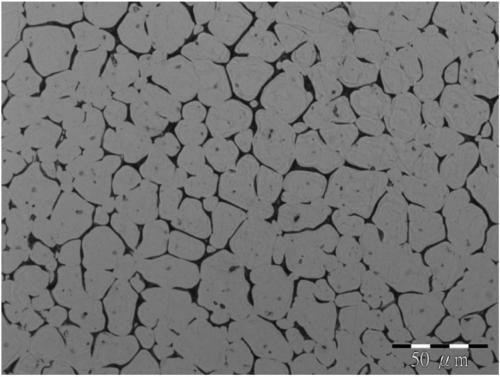

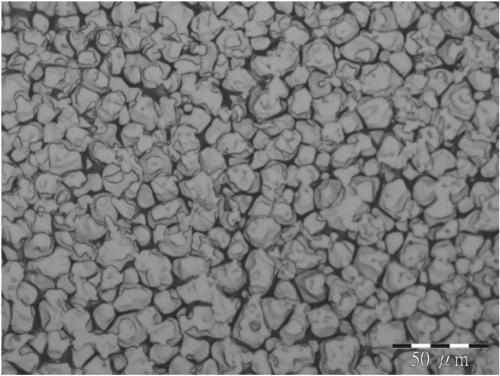

[0035] Examples 1 to 19: Nickel-rhenium alloy target

[0036] According to the composition of the nickel-rhenium alloy target shown in Table 1 below, weigh and mix appropriate amounts of nickel (Ni), rhenium (Re), iron (Fe), the first metal component (M1) and the second metal component (M2 ) and other raw materials, using vacuum induction melting method, in 5×10 -2 The vacuum environment of Thor, the reaction condition of 100°C higher than the pouring temperature, after holding the temperature, cast at the pouring temperature of 1650°C to 1670°C to obtain a pre-alloyed ingot. Here, the first metal component can be aluminum (Al), zirconium (Zr) or a combination thereof, and the second metal component includes titanium (Ti), osmium (Os), iridium (Ir), yttrium (Y), tantalum (Ta ), niobium (Nb), molybdenum (Mo), or combinations thereof.

[0037] After that, using atomization granulation equipment, at 1×10 -2 Torr to 1×10 -5 The pre-alloyed ingot is atomized into a pre-alloyed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com