Rare earth permanent magnetic material and preparation method thereof

A rare-earth permanent magnet and rare-earth element technology, which is applied in the direction of magnetic materials, inorganic material magnetism, and magnetic objects, can solve the problems of high processing costs, inability to diffuse heavy rare-earth elements, and limited diffusion depth of elements, and improve production efficiency. Reduce the cost of preparation and processing, and minimize the effect of remanent magnetism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

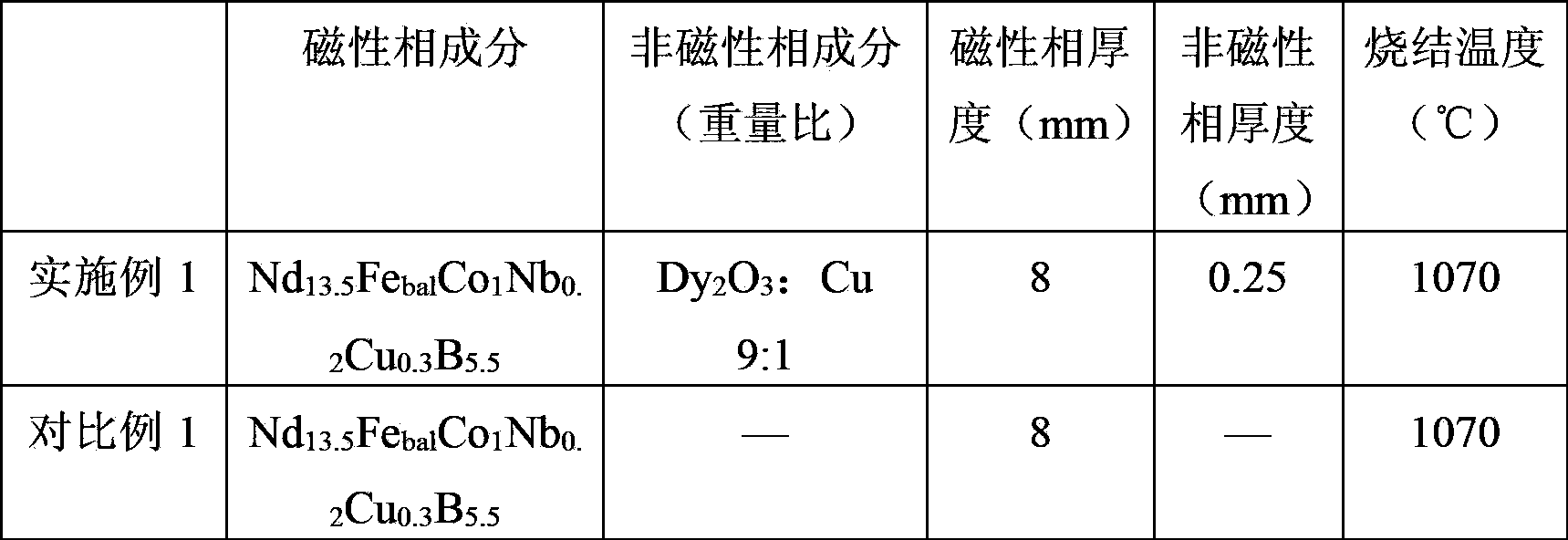

Embodiment 1 and comparative example 1

[0024] Proportioning is carried out according to the composition ratio, and Nd, Fe, Co, Nb, Cu and BFe alloys with a purity greater than 99% (weight percent) are used. Melt at intermediate frequency in an argon atmosphere, and then cast the molten steel on a water-cooled copper roll with a rolling speed of 1.5m / s to prepare a quick-setting sheet. The average thickness of quick-setting flakes is 0.25mm, and the composition is Nd 13.5 Fe bal co 1 Nb 0.2 Cu 0.3 B 5.5 (atomic percent).

[0025] Use hydrogen crushing or mechanical crushing to first coarsely crush the alloy into particles of about 0.5mm, and then use airflow milling to crush the alloy into a fine powder with an average particle size of 3.8um. The magnetic powder is oriented in a 2T magnetic field and simultaneously applied with The forming is carried out under the pressure perpendicular to the orientation field, the pressure is 70 MPa, and a blank with a thickness direction of 8 mm is obtained.

[0026] The...

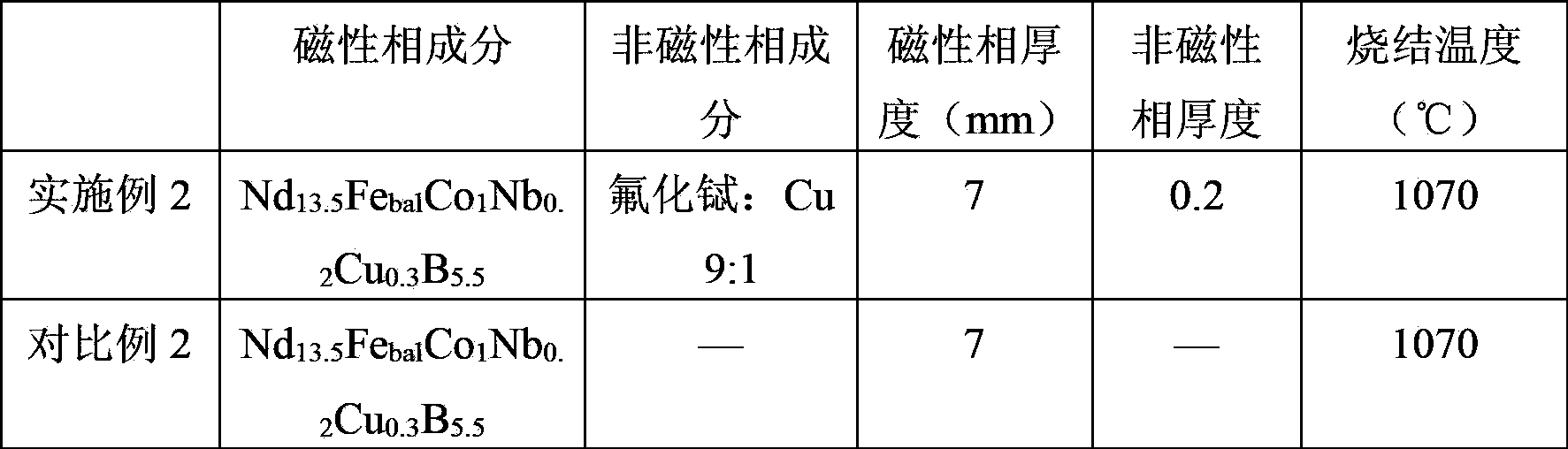

Embodiment 2 and comparative example 2

[0036] Proportioning is carried out according to the composition ratio, and Nd, Fe, Co, Nb, Cu and BFe alloys with a purity greater than 99% (weight percent) are used. Melt with intermediate frequency in 0.04MPA argon atmosphere, and then cast the molten steel on a water-cooled copper roller with a rolling speed of 2m / s to prepare quick-setting flakes. The average thickness of the quick-setting flakes is 0.23mm, and the composition is Nd 13.5 Fe bal co 1 Nb 0.2 Cu 0.3 B 5.5 (atomic percent).

[0037] Use hydrogen crushing or mechanical crushing to first coarsely crush the alloy into particles of about 0.5mm, and then use airflow milling to crush the alloy into a fine powder with an average particle size of 3.8um. The magnetic powder is oriented in a 2T magnetic field and simultaneously applied with The orientation field is parallel or perpendicular to the pressure for forming, the pressure is 70MPa, and the blank with the thickness direction of 8mm is obtained.

[0038...

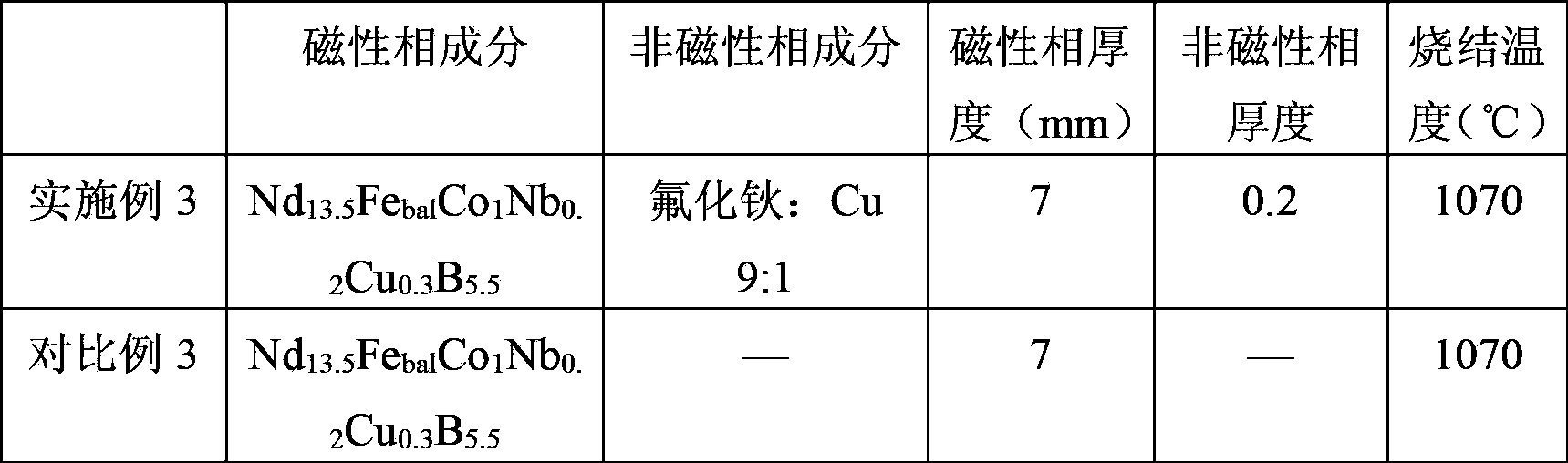

Embodiment 3 and comparative example 3

[0048] Proportioning is carried out according to the composition ratio, and Nd, Fe, Co, Nb, Cu and BFe alloys with a purity greater than 99% (weight percent) are used. Melt with intermediate frequency in 0.04MPA argon atmosphere, and then cast the molten steel on a water-cooled copper roller with a rolling speed of 2m / s to prepare quick-setting flakes. The average thickness of quick-setting flakes is 0.23mm, and the composition is Nd 13.5 Fe bal co 1 Nb 0.2 Cu 0.3 B 5.5 (atomic percent).

[0049] Use hydrogen crushing or mechanical crushing to first coarsely crush the alloy into particles of about 0.5mm, and then use airflow milling to crush the alloy into a fine powder with an average particle size of 3.8um. The magnetic powder is oriented in a 2T magnetic field and simultaneously applied with The orientation field is parallel or perpendicular to the pressure for forming, the pressure is 70MPa, and the blank with the thickness direction of 8mm is obtained.

[0050] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com