Plating solution formula of chemical nickel-phosphate plating alloy

An electroless nickel-plating phosphorus and plating solution technology, which is applied in the field of metal surface treatment, can solve the problems that phosphorus cannot be recycled and the utilization rate of phosphorus is not high, and achieve good promotion and application value, improve self-catalysis activity, and simple implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Prepare a kind of nickel-phosphorus electroless plating solution of novel additive according to following formula:

[0020] Nickel sulfate hexahydrate 20g

[0021] Sodium hypophosphite 15g

[0022] Polyvinylpyrrolidone (PVP) 100g

[0023] Sodium Lactate Buffer (PH4.5) 7mg

[0024] Lactic acid 4mg

[0025] Glycine 1.5g

[0026] Sodium thiosulfate 30μg

[0027] Thiourea 10μg

[0028] The balance is water.

[0029] After preparing the solutions in proportion, measure the pH value, and adjust the pH to 4.7 with dilute sulfuric acid and potassium bicarbonate solution, and the plating temperature is 75°C.

[0030] The obtained nickel-phosphorus alloy coating performance index:

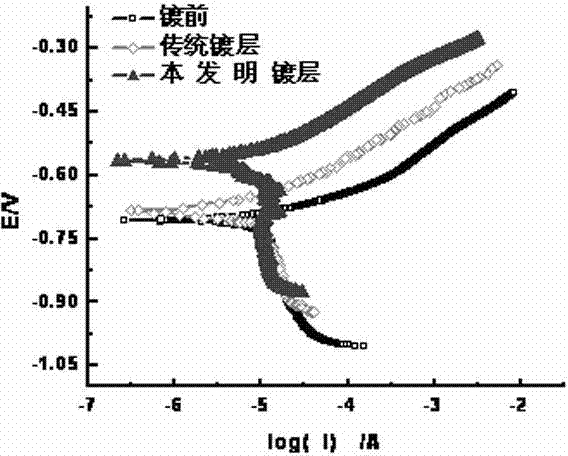

[0031] Corrosion potential 535mV vs SCE

[0032] Neutral salt spray test (25μm) 2000~2500h

[0033] Deposition rate 20μm / h

[0034] Microhardness 1850HV

[0035] Porosity None

[0036] The microhardness adopts HXR-1000TM digital microhardness tester, and the neutral salt spray adopts Shan...

Embodiment 2

[0038] Prepare a kind of nickel-phosphorus electroless plating solution of novel additive according to following formula:

[0039] Nickel sulfate hexahydrate 25g

[0040] Sodium hypophosphite 20g

[0041] Polyvinylpyrrolidone (PVP) 100g

[0042] Sodium Lactate Buffer (PH4.5) 7mg

[0043] Lactic acid 4mg

[0044] Glycine 2g

[0045] Sodium thiosulfate 30μg

[0046] Thiourea 10μg

[0047] The balance is water.

[0048] After preparing the solutions in proportion, measure the pH value, and adjust the pH to 4.7 with dilute sulfuric acid and potassium bicarbonate solution, and the plating temperature is 75°C.

[0049] The obtained nickel-phosphorus alloy coating performance index:

[0050] Corrosion potential 405mV vs SCE

[0051] Neutral salt spray test (25μm) 1200~2500h

[0052] Deposition rate 22μm / h

[0053] Microhardness 2500HV

[0054] Porosity None

[0055] The microhardness adopts HXR-1000TM digital microhardness tester, and the neutral salt spray adopts Shangh...

Embodiment 3

[0057] Prepare a kind of nickel-phosphorus electroless plating solution of novel additive according to following formula:

[0058] Nickel sulfate hexahydrate 40g

[0059] Sodium hypophosphite 30g

[0060] Polyvinylpyrrolidone (PVP) 120g

[0061] Sodium Lactate Buffer (PH4.5) 5mg

[0062]Lactic acid 2mg

[0063] Glycine 3g

[0064] Sodium thiosulfate 30μg

[0065] Thiourea 20μg

[0066] The balance is water.

[0067] After preparing the solutions in proportion, measure the pH value, and adjust the pH to 4.7 with dilute sulfuric acid and potassium bicarbonate solution, and the plating temperature is 75°C.

[0068] The obtained nickel-phosphorus alloy coating performance index:

[0069] Corrosion potential 375mV vs SCE

[0070] Neutral salt spray test (25μm) 1800~3000h

[0071] Deposition rate 17μm / h

[0072] Microhardness 2000HV

[0073] Porosity None

[0074] The microhardness adopts HXR-1000TM digital microhardness tester, and the neutral salt spray adopts Shangha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Microhardness | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com