Chemical nickel-phosphorus alloy plating solution

An electroless nickel-phosphorus plating and plating solution technology, applied in the field of metal surface treatment, can solve the problems of high production cost, slightly exceeding 20 μm/h, generally less than 20 μm/h, and less than 10 μm/h, and achieve good promotion and application Value, broaden the pH range, reduce the effect of plating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

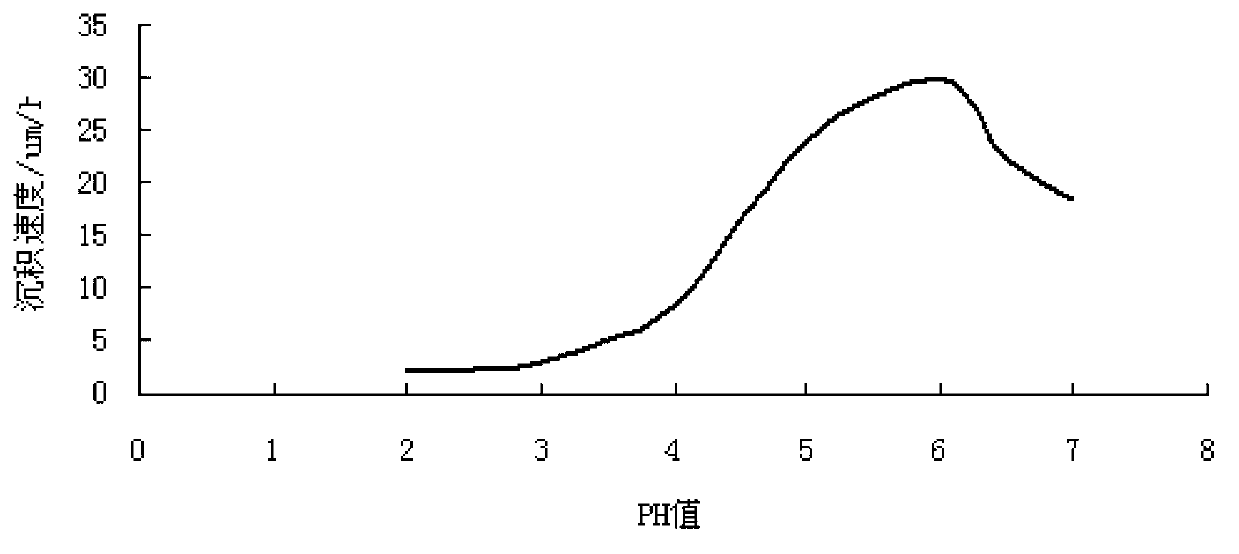

[0025] Embodiment 1: the influence of pH value on deposition rate

[0026] The technological formula is: nickel sulfate hexahydrate 40g / L, sodium hypophosphite dihydrate 40g / L, lactic acid 20ml / L, sodium acetate 15g / L, urea 10g / L; the temperature is 80-83°C.

[0027] When the pH value is 3, the deposition rate is 3.2 μm / h; when the pH value is 4, the deposition rate is 8.4 μm / h; when the pH value is 5, the deposition rate is 23.8 μm / h; when the pH value is 6, the deposition rate is 30.1 μm / h; It is 6.5, and the deposition rate is 22.3 μm / h.

[0028] The experimental results show that the reduction of sodium hypophosphite is enhanced with the increase of pH value, and the deposition rate of the alloy is accelerated; when the pH value is very low, the deposition rate is small; with the increase of pH value, the deposition rate is accelerated. When the pH value rises to 5.5-6, the deposition rate is the fastest; when the pH value is above 6, the deposition rate decreases with th...

Embodiment 2

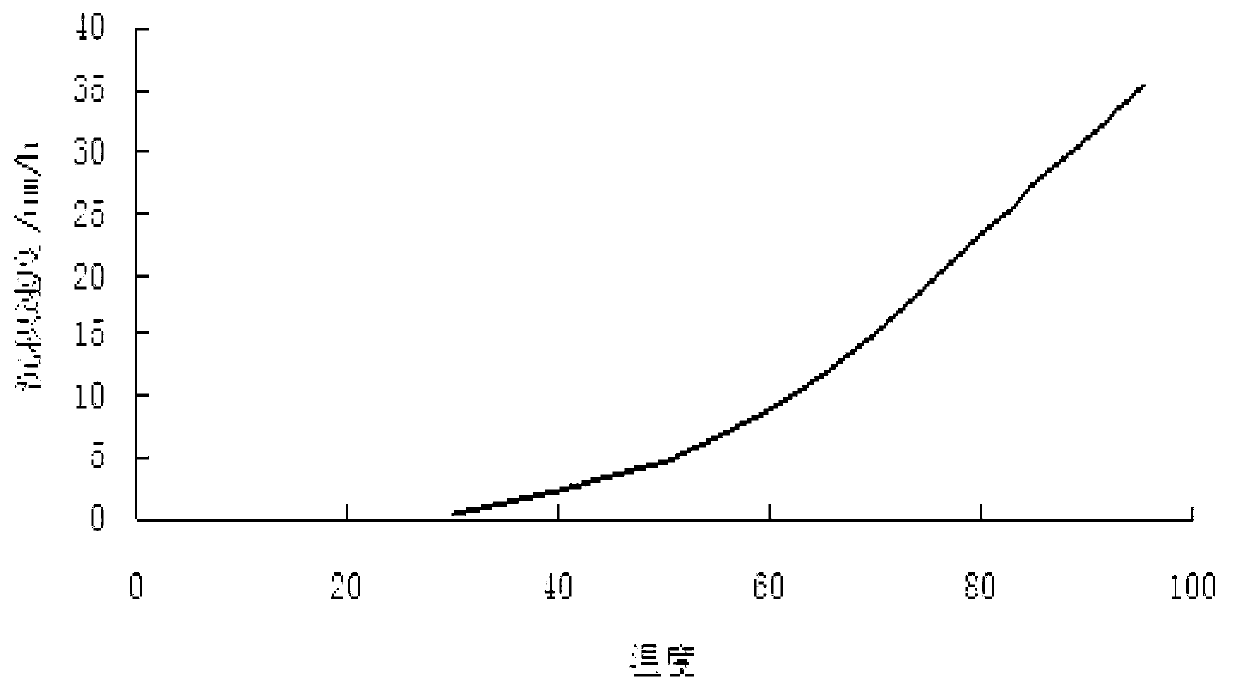

[0029] Embodiment 2: the influence of temperature on deposition rate

[0030] The technological formula is: nickel sulfate hexahydrate 40g / L, sodium hypophosphite dihydrate 40g / L, lactic acid 20ml / L, sodium acetate 15g / L, urea 10g / L; pH value is 5.0-5.1.

[0031] The deposition rate at 30°C is 0.2 μm / h, the deposition rate at 40°C is 2.3 μm / h, the deposition rate at 50°C is 4.6 μm / h, the deposition rate at 60°C is 8.9 μm / h, the deposition rate at 70°C is 15.2 μm / h, and the deposition rate at 80°C is 23.2 μm / h, the deposition rate at 90°C is 31.2 μm / h; the deposition rate at 95°C is 35.2 μm / h.

[0032] Experimental results show that nickel-phosphorus alloy coatings can be obtained in the range of 30-95°C. In the range of 30-50 °C, the deposition rate increases slowly with the increase of temperature; at 50-80 °C, the deposition rate increases rapidly with the increase of temperature; after 80 °C, the increase of deposition rate slows down slightly with the increase of temperat...

Embodiment 3

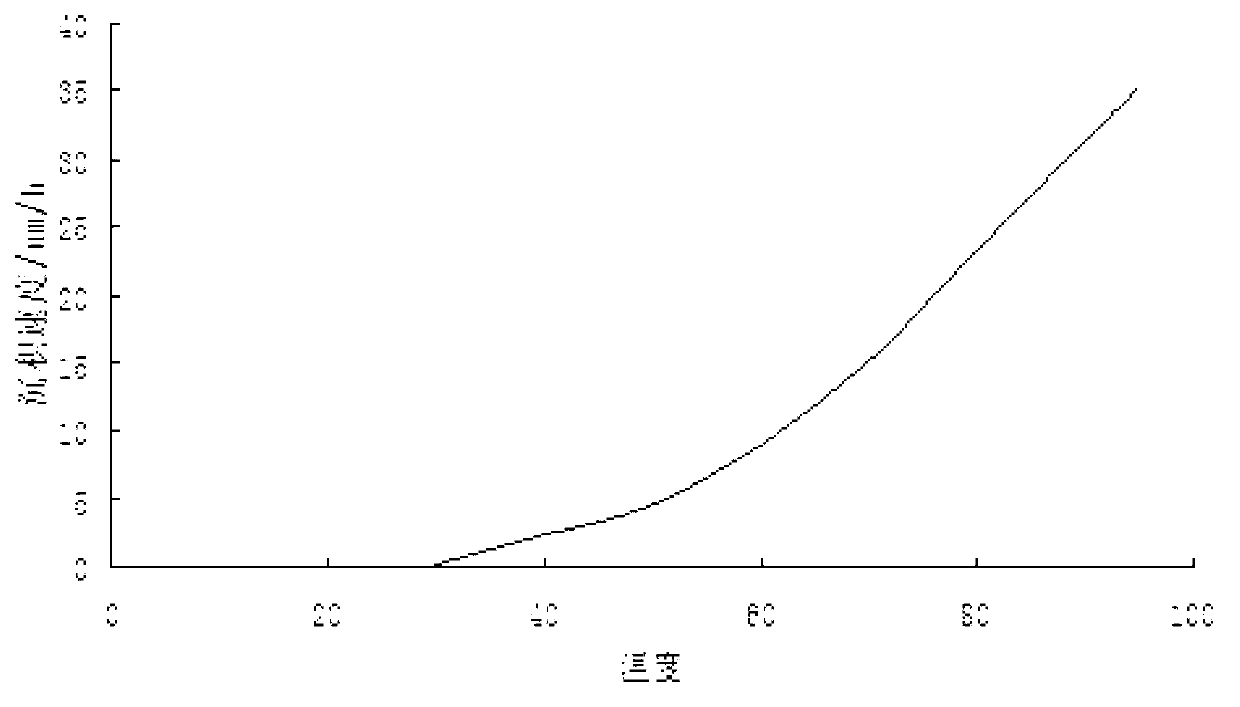

[0033] Embodiment 3: the influence of urea on deposition temperature and deposition rate

[0034] The technological formula is: 40g / L of nickel sulfate hexahydrate, 40g / L of sodium hypophosphite dihydrate, 20ml / L of lactic acid, 15g / L of sodium acetate, and the pH value is 5.0-5.1.

[0035] (1) Effect of urea on deposition temperature

[0036] When urea is not added, the deposition rate is 0 μm / h at 30°C, 0 μm / h at 40°C, 0.5 μm / h at 50°C, 2.9 μm / h at 60°C, 10.2 μm / h at 70°C, and 10.2 μm / h at 80°C The deposition rate is 13.7 μm / h, the deposition rate at 90°C is 18.4 μm / h; the deposition rate at 95°C is 21.3 μm / h.

[0037] (2) Effect of urea on deposition rate

[0038] When the temperature is controlled at 80-83°C, the deposition rate of 1g / L urea is 18.2μm / h, the deposition rate of 5g / L urea is 21.5μm / h, the deposition rate of 10g / L urea is 23.1μm / h, 15g / L The deposition rate of urea is 24.7μm / h, and the deposition rate of 20g / L urea is 23.4μm / h.

[0039] The experimental r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com