Anisotropic conducting film and manufacturing method for same

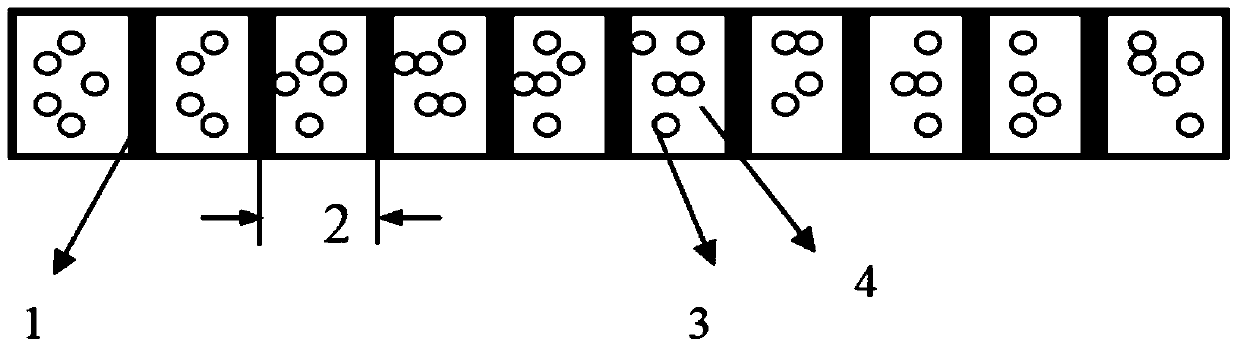

An anisotropic, conductive film technology, applied in the direction of cable/conductor manufacturing, conductive adhesive connection, conductive materials dispersed in non-conductive inorganic materials, etc., can solve the poor filling rate of conductive particles in the uniformity of pores, porous Complicated film process and other issues, to achieve good vertical conduction and lateral insulation, improve vertical conduction performance, and increase the effect of filling density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Dissolve 50 grams of polyimide in 150 ml of dimethylacetamide to form a solution with a viscosity of 0.5 Pa·s. Using a screen with a strip pattern with a pitch of 2 μm, the above solution is printed and coated on the substrate by a screen printing process, and the printing and coating operation is repeated several times to form a plurality of isolations with a pitch of 2 μm on the substrate. film layer. After heating and curing at 120° C. for 30 minutes, a plurality of completely cured isolation layers with a height of 15 μm were formed on the substrate.

[0069] 60 gram epoxy resins (JE6110-3) are dissolved in the organic solvent of 170ml toluene / ethyl acetate, then add 3ml latent curing agent (2-heptadecyl imidazole modified curing agent), then 120 grams particle size Conductive gold balls with a diameter of 5 μm were dispersed therein to form a mixed solution containing conductive particles and a resin binder.

[0070] The substrate formed with multiple isolation l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com