Hyacinth-like coated glass and preparation method thereof

A technology for coating glass and hyacinth stone, which is applied in chemical instruments and methods, glass/slag layered products, layered products, etc. High hardness, the effect of delaying the oxidation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

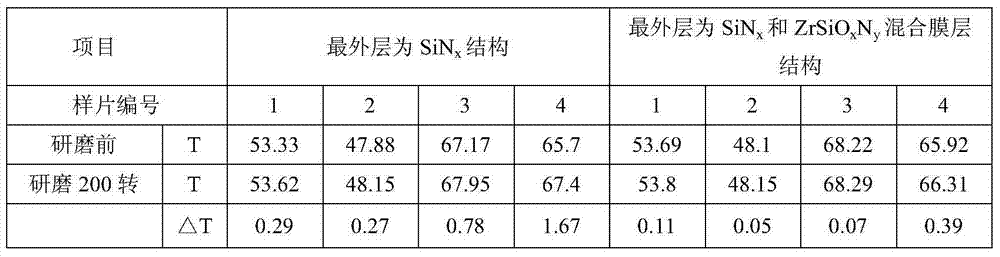

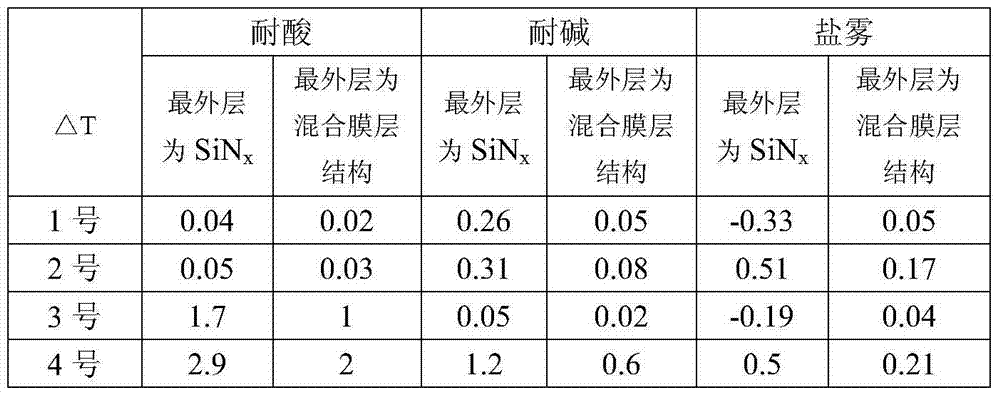

Examples

Embodiment 1

[0036] A kind of low-radiation coated glass is plated by magnetron sputtering deposition method, the glass substrate, the functional film system layer coated on the surface of the glass substrate and the hyacinoid stone plated on the surface of the functional film system layer are mixed and mixed. Miscellaneous film layer, the above-mentioned film layers include in order from the glass substrate outward:

[0037] The base dielectric layer plated on the glass substrate, the material of the film layer is: titanium oxide film layer, and the thick plating is about 12nm.

[0038] The film material of the first barrier layer plated on the base dielectric layer is: a nickel-chromium alloy film layer with a thickness of about 4nm.

[0039] The material of the functional layer plated on the first barrier layer is: silver simple film layer with a thickness of about 12nm.

[0040] The film material of the second barrier layer plated on the functional layer is: a nickel-chromium alloy fi...

Embodiment 2

[0045] A low-radiation coated glass, a glass substrate, a functional film system layer coated on the surface of the glass substrate, and a hyacinoid mixed-doped film layer coated on the surface of the functional film system layer. The glass substrate outwardly includes:

[0046] The base dielectric layer plated on the glass substrate, the material of the film layer is: titanium oxide film layer, and the thick plating is about 12nm.

[0047] The film material of the first barrier layer plated on the base dielectric layer is: a nickel-chromium alloy film layer with a thickness of about 4nm.

[0048] The material of the functional layer plated on the first barrier layer is: silver simple film layer with a thickness of about 12nm.

[0049] The film material of the second barrier layer plated on the functional layer is: a nickel-chromium alloy film with a thickness of about 1 nm.

[0050] The top dielectric layer plated on the second barrier layer is made of silicon oxide film wi...

Embodiment 3

[0054] A low-radiation coated glass, a glass substrate, a functional film system layer coated on the surface of the glass substrate, and a hyacinoid mixed-doped film layer coated on the surface of the functional film system layer. The glass substrate outwardly includes:

[0055] The material of the first dielectric layer plated on the glass substrate is: zinc tin oxide film layer, and the thickness of the film layer is about 39.4nm.

[0056] The film material of the first barrier layer plated on the first dielectric layer is: nickel-chromium alloy film layer 3nm.

[0057] The material of the functional layer plated on the first barrier layer is silver-copper alloy with a thickness of about 6.7nm.

[0058] The film material of the second barrier layer plated on the functional layer is: nickel-chromium alloy film layer 1nm.

[0059] The material of the second dielectric layer plated on the second barrier layer is zinc oxide 20nm.

[0060] The top dielectric layer plated on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com