A terbium ytterbium rare earth ion double-doped lutetium gadolinium lithium fluoride up-conversion luminescent crystal and preparation method thereof

A technology of mixed lutetium-gadolinium fluoride and lutetium-gadolinium fluoride, which is applied in the field of up-conversion luminescent single crystals, can solve problems such as equipment loss, poor crystal quality, and large crystal stress, and achieve electricity cost savings and uniform ion distribution , The effect of small crystal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

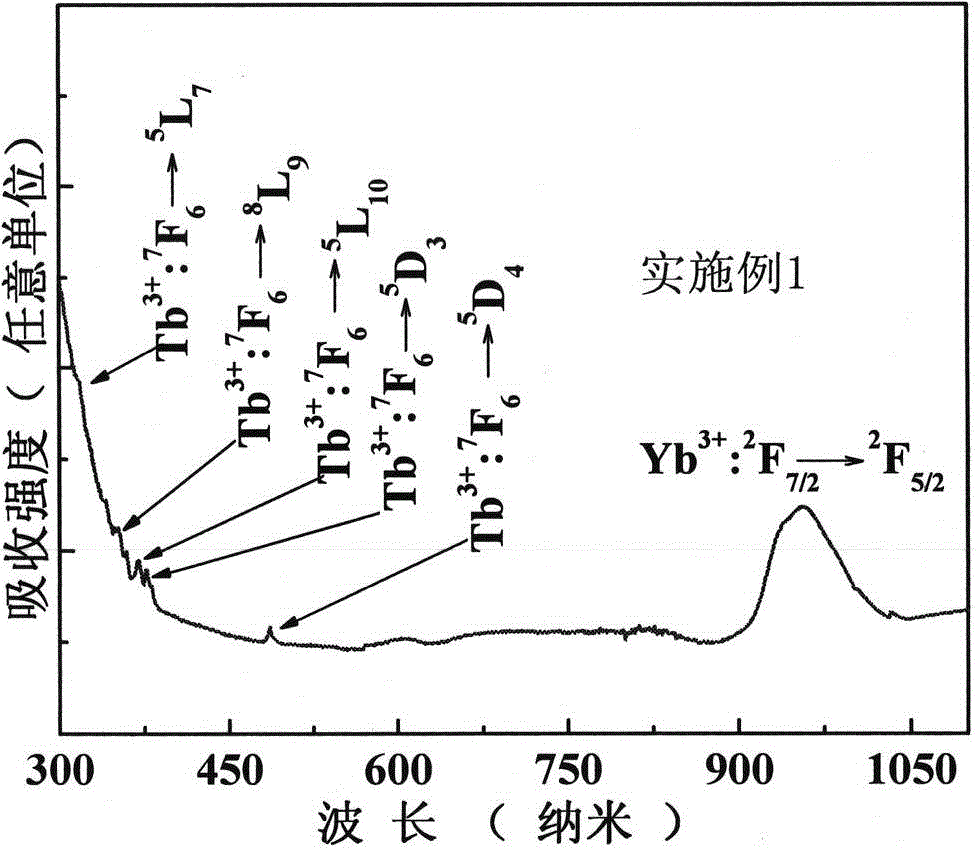

[0024] LiF, LuF with a purity greater than 99.99% 3 , GdF 3 , YbF 3 , TbF 3 Mix according to the molar percentage ratio of 51.5:36.183:10.0:2.0:0.317, place in a mill, grind and mix for 5 hours to obtain a mixture of uniform powder, place the mixture in a boat-shaped platinum crucible, and then install it in a tube In the platinum pipe of the type resistance furnace, and then use N 2 Remove the air in the platinum pipeline, and then gradually raise the temperature of the furnace body to 740°C, and conduct reaction treatment for 2 hours under HF gas, and the reaction treatment is completed. Tube resistance furnace, with N 2 The residual HF gas in the gas cleaning pipeline is gradually cooled to room temperature to obtain polycrystalline powder. The polycrystalline powder is placed in a mill and ground into powder, then placed in a Pt crucible and compacted, and the Pt crucible is sealed. The Pt crucible is placed in a silicon-molybdenum rod furnace, and the crystal is grow...

Embodiment 2

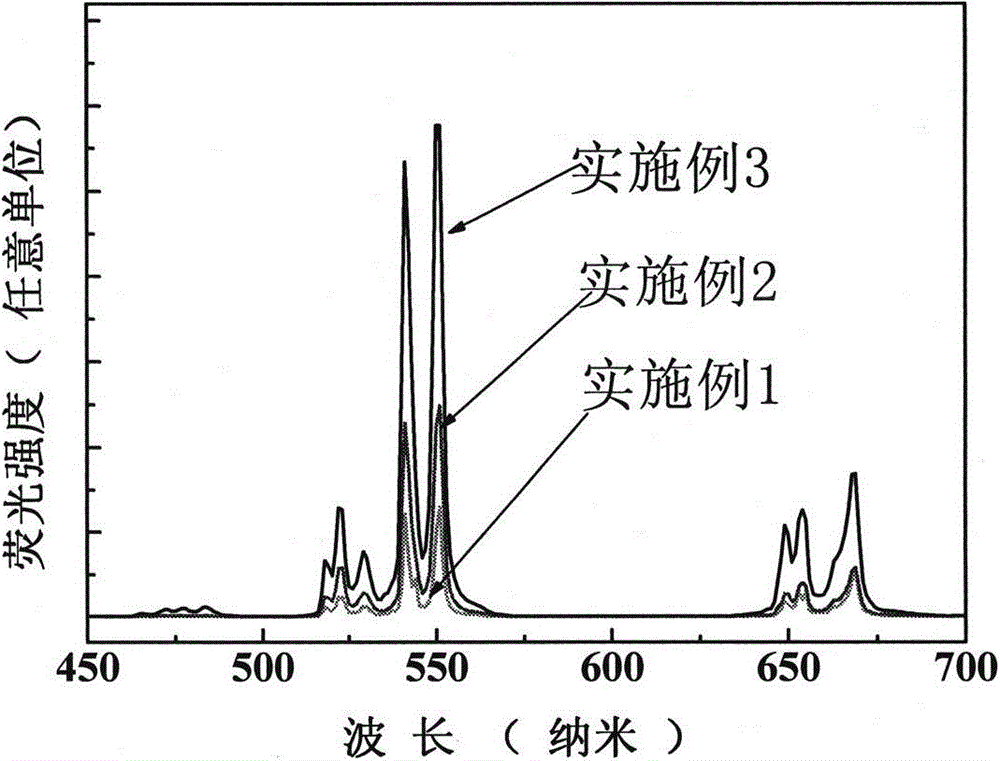

[0026] Basically the same as embodiment 1, the difference is only LiF, LuF 3 , GdF 3 , YbF 3 , TbF 3 Mix according to the molar percentage ratio of 51.5: 33.183: 10.0: 5.0: 0.317, and react for 3 hours. The temperature gradient of the solid-liquid interface is 50°C / cm, and the crucible descending speed is 0.5mm / h. The furnace temperature was lowered to room temperature at 50° C. in one hour, and the samples were taken to measure α=0.071, β=0.0496, and γ=0.0032. The chemical formula of the single crystal is LiLu 0.8762 Gd 0.071 Yb 0.0496 Tb 00032 f 4 , and each sample obtained was polished into a thin slice with a thickness of 2 mm. Keeping the same optical test conditions as in Example 1, the obtained fluorescence intensity is comparable to that of the sample in Example 1. Under 960nm light excitation, under 960nm red light excitation, the upconversion fluorescence of embodiment 1 sees figure 2 , the intensity of blue light in the 550nm band is 12.40 units.

Embodiment 3

[0028] Basically the same as embodiment 1, the difference is only LiF, LuF 3 , GdF 3 , YbF 3 , TbF 3 Mix according to the molar percentage ratio of 51.5:30.183:10.0:8.0:0.317, and react for 4 hours. The temperature gradient of the solid-liquid interface is 80°C / cm, and the crucible descending speed is 1mm / h. The temperature of the furnace was lowered to room temperature at 70°C, and α=0.071, β=0.0793, and γ=0.0032 were measured by sampling. The chemical formula of the single crystal is LiLu 0.8465 Gd 0.071 Yb 0.0793 Tb 0.0032 f 4 , and each sample obtained was polished into a thin slice with a thickness of 2 mm. Keeping the same optical test conditions as in Example 1, the obtained fluorescence intensity is comparable to that of the sample in Example 1. Under 960nm light excitation, under 960nm red light excitation, the upconversion fluorescence of embodiment 1 sees figure 2 , the intensity of blue light in the 550nm band is 28.90 units.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com