Quantum dot/acrylate polymer nanocrystal composite, preparation method and color conversion film

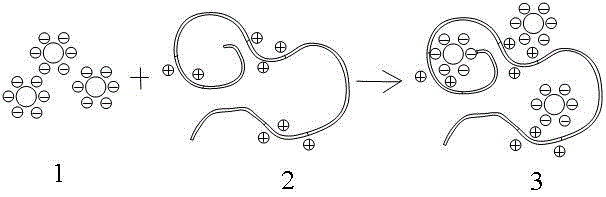

A technology of color conversion film and acrylate, which is applied to the coating equipment of photoengraving process and the photosensitive material used for opto-mechanical equipment, etc., can solve the problems of low color gamut, low utilization rate of light source, and not enough vivid and true colors, etc. To achieve high luminous efficiency, easy to disperse, to ensure the effect of photoluminescence characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067]Under a nitrogen atmosphere, polymerize β-hydroxyethyl methacrylate and dimethylaminoethyl methacrylate according to a molar ratio of 1:1 to obtain random polymers, and further, add dimethylaminoethyl methacrylate Equimolar ratio of chlorohydrin, ionized to obtain a cationic acrylate polymer containing ammonium ions. Dissolve it in THF solution to obtain a concentration of 0.5 mgmL -1 Tetrahydrofuran solutions of cationic acrylate polymers, thioglycolic acid ligand-stabilized CdTe / ZnS quantum dots were dissolved in acetone to prepare 0.2mgmL -1 quantum dot nanocrystal solution. Under mechanical stirring, mix 20mL ionic acrylate polymer solution with 15mL quantum dot nanocrystal solution, continue mechanical stirring for 0.5h, then add 100mL precipitant methanol solution of ionic acrylate polymer, remove supernatant, take The precipitate is put into a vacuum oven to remove the residual solvent, and then a CdTe / ZnS quantum dot / ionic acrylate polymer nanocrystal composite...

Embodiment 2

[0073] Under a nitrogen atmosphere, cyclohexyl methacrylate and N-vinylimidazole are polymerized according to a molar ratio of 3:2 to obtain a block polymer, and further, lauryl chloride and N-vinylimidazole in an equimolar ratio are added, and the ions to obtain ionic acrylate polymers. Take 5g and heat it to the melting temperature of 180-200°C. Under mechanical stirring, disperse 2.5g of negatively charged oleic acid-stabilized CdSe / CdS quantum dot powder into the molten ionic acrylate polymer, and continue mechanical stirring After 2 hours, the temperature was naturally lowered to room temperature to obtain a quantum dot / acrylate polymer nanocrystal composite, which was kept in a desiccator (the entire composite process was completed under the protection of an inert gas).

[0074] The preparation method of described color conversion film comprises the following steps:

[0075] i) Disperse the CdSe / CdS quantum dots / ionic acrylate polymer nanocrystal composite in the photor...

Embodiment 3

[0079] Under a nitrogen atmosphere, the block polymer obtained by polymerizing lauryl methacrylate and p-chloromethyl styrene according to the molar ratio of 2:1, further, adding N-formaldehyde in an equimolar ratio to p-chloromethyl styrene Based imidazole, ionized to prepare cationic acrylate polymer. Dissolve it in chloroform hot liquid to obtain a concentration of 0.2 mgmL -1 Chloroform solutions of cationic acrylate polymers, 0.1mgmL -1 quantum dot nanocrystal solution. Under mechanical stirring, mix 10mL of imidazolium ionic acrylate polymer solution with 10mL of quantum dot solution, continue mechanical stirring for 0.5h, let stand to separate layers, the quantum dots will be extracted into the ionic acrylate polymer chloroform solution, take out One layer of chloroform solution of ionic acrylate polymer, the solvent is removed by rotary evaporation, and then the quantum dot / acrylate polymer nanocrystal composite is obtained, which is kept in a desiccator for future u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com