Method for preparing BOE (Buffer Oxide Etch) etching liquid

An etching solution and concentration technology, applied in chemical instruments and methods, surface etching compositions, etc., can solve the problems of complex penetration, slow spreading speed, poor microscopic surface ability, etc., achieve simple operation, reduce contact angle, and reduce impurity content. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The preparation method of BOE etchant comprises the steps:

[0022] (1) Add 49wt% electronic grade hydrofluoric acid (HF), 30wt% electronic grade ammonia, and ultrapure water to the reactor in turn, and stir and react at room temperature for 6 hours. Excessive hydrofluoric acid (HF ) reacts with ammonia water to partially convert to ammonium fluoride (NH 4 F), to get hydrofluoric acid (HF) and ammonium fluoride (NH 4 F) mixtures;

[0023] (2) After the mixture obtained in step (1) is cooled to room temperature, add additives and lauryl ammonium sulfate anionic surfactant in turn, stir and mix at room temperature for 12 hours, mix well, and filter with a filter screen with a pore size of 0.2 μm Finally, a transparent BOE etching solution is obtained. The concentration of hydrofluoric acid (HF) in the obtained BOE etching solution is 15wt%, and ammonium fluoride (NH 4 F) The concentration is 30 wt%.

Embodiment 2-7

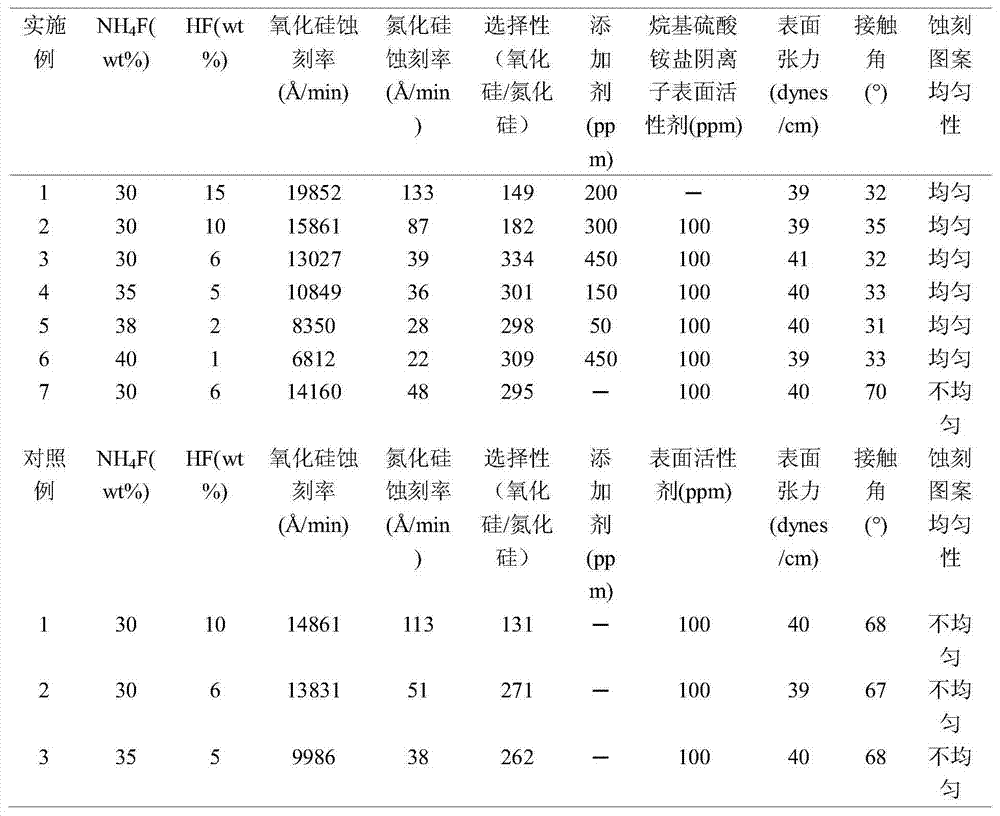

[0025] Following the exact same steps as above, only the above raw materials are changed, and the concentration of hydrofluoric acid (HF) in the BOE etching solution and the concentration of ammonium fluoride (NH 4 F) Concentration, see Table 1.

[0026] The components contained in the etching solution are shown in Table 1. Wherein embodiment 1 additive is succinic acid, amylamine, and consumption is respectively 150ppm, 50ppm; Embodiment 2 additive is undecanoic acid, decylamine, and consumption is respectively 200ppm, 100ppm; Embodiment 3 additive is methylethanolamine, isopropyl Alcohol and valeric acid, consumption is respectively 50ppm, 300ppm and 100ppm; Embodiment 4 additive is dodecylamine, octanol, consumption is respectively 50ppm, 100ppm; Embodiment 5 additive is hexanoic acid, dodecyl alcohol, consumption is respectively 25ppm, 25ppm ; Embodiment 6 additive is n-butanol, and consumption is 450ppm; Embodiment 7 has no additive.

[0027] Lauryl ammonium sulfate ani...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com