Method for manufacturing multilayer amorphous alloy and copper composite structure through intermediate layer diffusion

A technology of amorphous alloy and composite structure, which is applied in the direction of welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve the problems that cannot be directly diffused to prepare multi-layer amorphous alloy and copper composite structure, and achieve easy promotion and use and enhanced toughness , Enhance the effect of shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

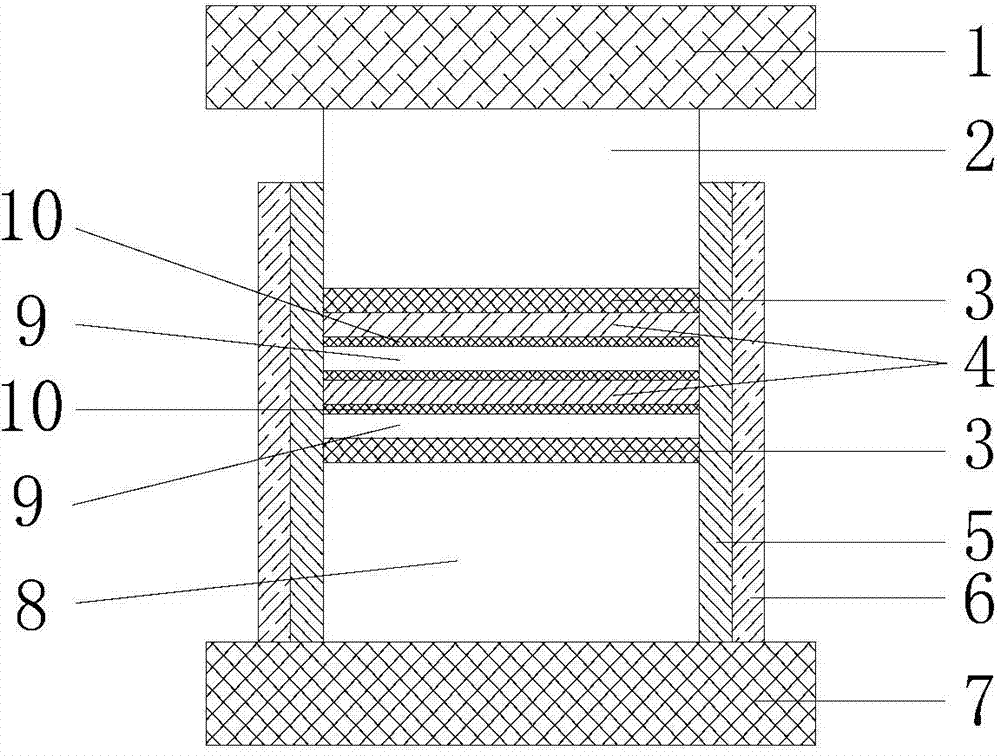

Image

Examples

Embodiment 1

[0055] First place the thickness of 0.2mm on the Zr 41 Ti 14 Cu 12.5 Ni 10 be 22.5 The flakes and copper flakes are cut into specified sizes, and the aluminum foil with a thickness of 5um is divided into the same length and width as the amorphous alloy flakes. Use 800#, 1000#, 1200# sandpaper to polish the cross-section of the workpiece in sequence. After processing, the parallelism is better than 0.02mm, and polish it to better than 1.6um with a polishing cloth to remove the oxide layer. Put the workpiece in acetone and ultrasonically clean it for 15 minutes. After taking out the workpiece, put it into absolute ethanol for the second ultrasonic cleaning machine, and then put the cleaned workpiece into clean absolute ethanol for storage. Place the solder stop layer on the WC cemented carbide pressing head in order from bottom to top, and place Zr crosswise. 41 Ti 14 Cu 12.5 Ni 10 be 22.5 Thin sheet, aluminum foil, copper sheet, solder stop layer, and finally place the...

Embodiment 2

[0057] First place the thickness of 0.2mm on the Zr 55 Cu 30 Al 10 Ni 5 The flakes and copper flakes are cut into specified sizes, and the aluminum foil with a thickness of 5um is divided into the same length and width as the amorphous alloy flakes. Use 800#, 1000#, 1200# sandpaper to polish the cross-section of the workpiece in sequence. After processing, the parallelism is better than 0.02mm, and polish it to better than 1.6um with a polishing cloth to remove the oxide layer. Put the workpiece in acetone and ultrasonically clean it for 15 minutes. After taking out the workpiece, put it into absolute ethanol for the second ultrasonic cleaning machine, and then put the cleaned workpiece into clean absolute ethanol for storage. Place the solder stop layer on the WC cemented carbide pressing head in order from bottom to top, and place Zr crosswise. 55 Cu 30 Al 10 Ni 5 Thin sheet, aluminum foil, copper sheet, solder stop layer, and finally place the WC hard alloy upper ind...

Embodiment 3

[0059] First place the thickness of 0.2mm on the Zr 55 Cu 30 Al 10 Ni 5 The flakes and copper flakes are cut into specified sizes, and the aluminum foil with a thickness of 5um is divided into the same length and width as the amorphous alloy flakes. Use 800#, 1000#, 1200# sandpaper to polish the cross-section of amorphous alloy and copper sheet in sequence. After processing, the parallelism is better than 0.02mm, and polish it to better than 1.6um with a polishing cloth to remove the oxide layer. Put the workpiece in acetone and ultrasonically clean it for 15 minutes. After taking out the workpiece, put it into absolute ethanol for the second ultrasonic cleaning machine, and then put the cleaned workpiece into clean absolute ethanol for storage. Place the solder stop layer on the WC cemented carbide pressing head in order from bottom to top, and place Zr crosswise. 55 Cu 30 al 10 Ni 5 Thin sheet, aluminum foil, copper sheet, solder stop layer, and finally place the WC h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com