A preparation method of hydroxyapatite powder with controllable structure size for plasma thermal spraying

A hydroxyapatite and nano-hydroxyapatite technology, which is applied in the fields of nanotechnology, chemical instruments and methods, and phosphorus compounds for materials and surface science, can solve the problem of difficult to obtain hydroxyapatite hollow microspheres, Hydroxyapatite powder has low crystallinity and does not explain the effects of pore-forming agents, which can reduce the difficulty of preparation, improve rheological properties, and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

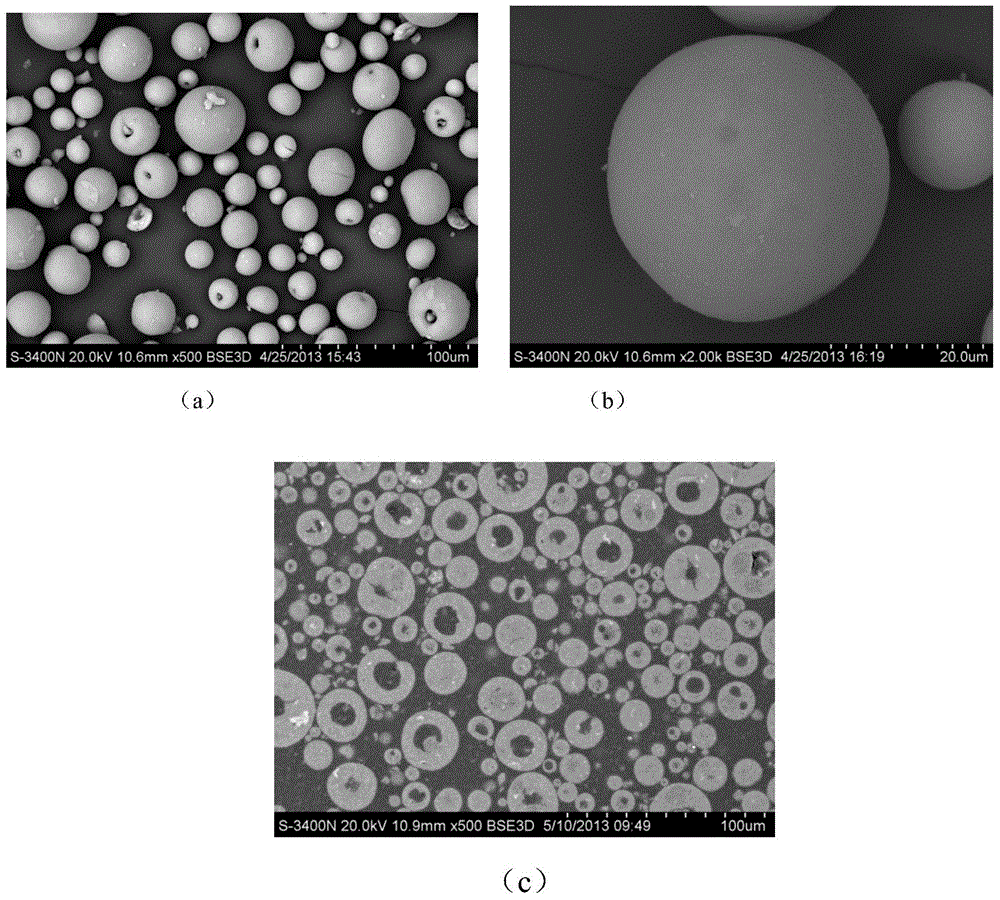

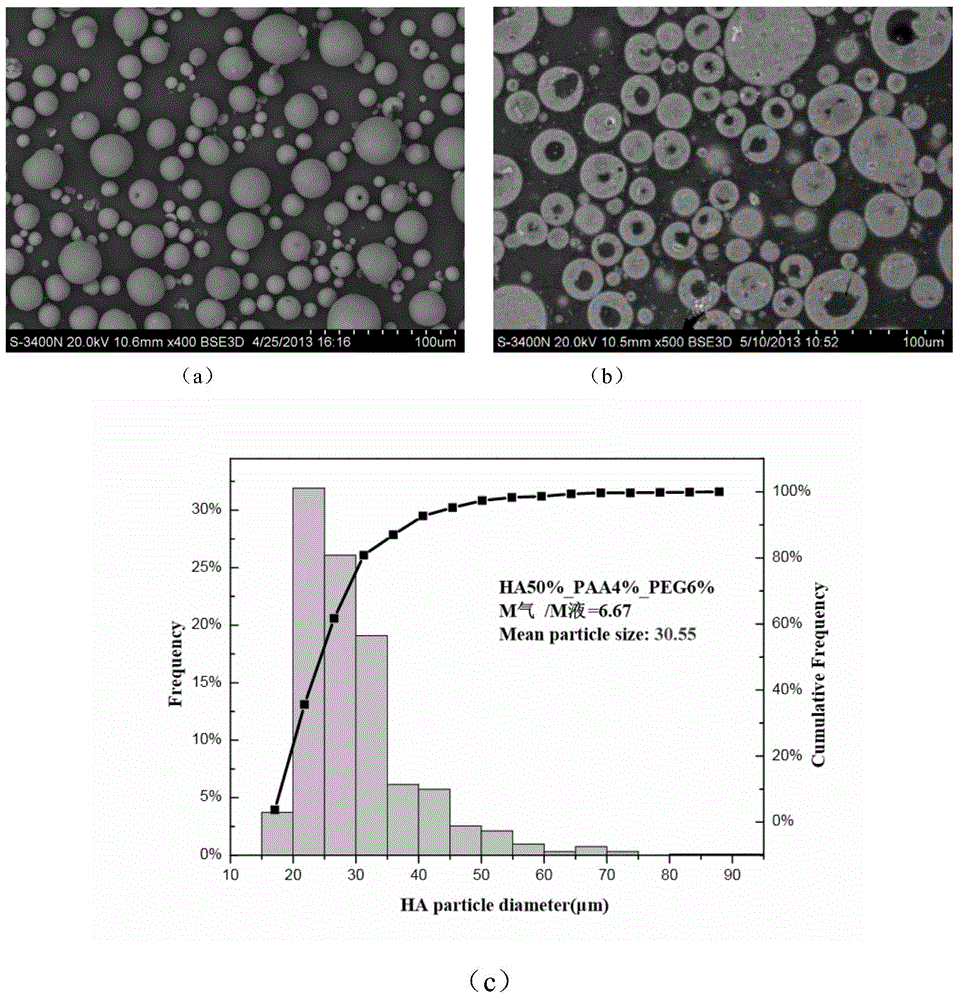

[0029] (1) Weigh 94g of deionized water and add it to the ball mill tank, add 10g of ammonium polyacrylate solution (40% by mass percentage concentration, the following concentrations are all mass percentage concentrations unless otherwise specified), take 100g of nano-hydroxyapatite and mix it, Prepare slurry (solid content 50%), ball mill for 5 hours, add 6g of polyethylene glycol, and continue ball milling for 5 hours;

[0030] (2) Spray-dry the uniformly mixed slurry, feed it under magnetic stirring, the nozzle diameter is 2mm, the inlet temperature is 170°C, the outlet temperature is 100°C, the feed rate is 13ml / min, the compressed air pressure 0.5MPa, compressed air flow rate is 1.5m 3 / h, M 气 / M 液 =6.67;

[0031] (3) Dry the powder obtained by spray drying at 80°C;

[0032] (4) Put the obtained powder in a resistance furnace (atmospheric atmosphere) for heat treatment, the heating rate is 5°C / min, first keep warm at 650°C for 3 hours, remove the organic additives in...

Embodiment 2

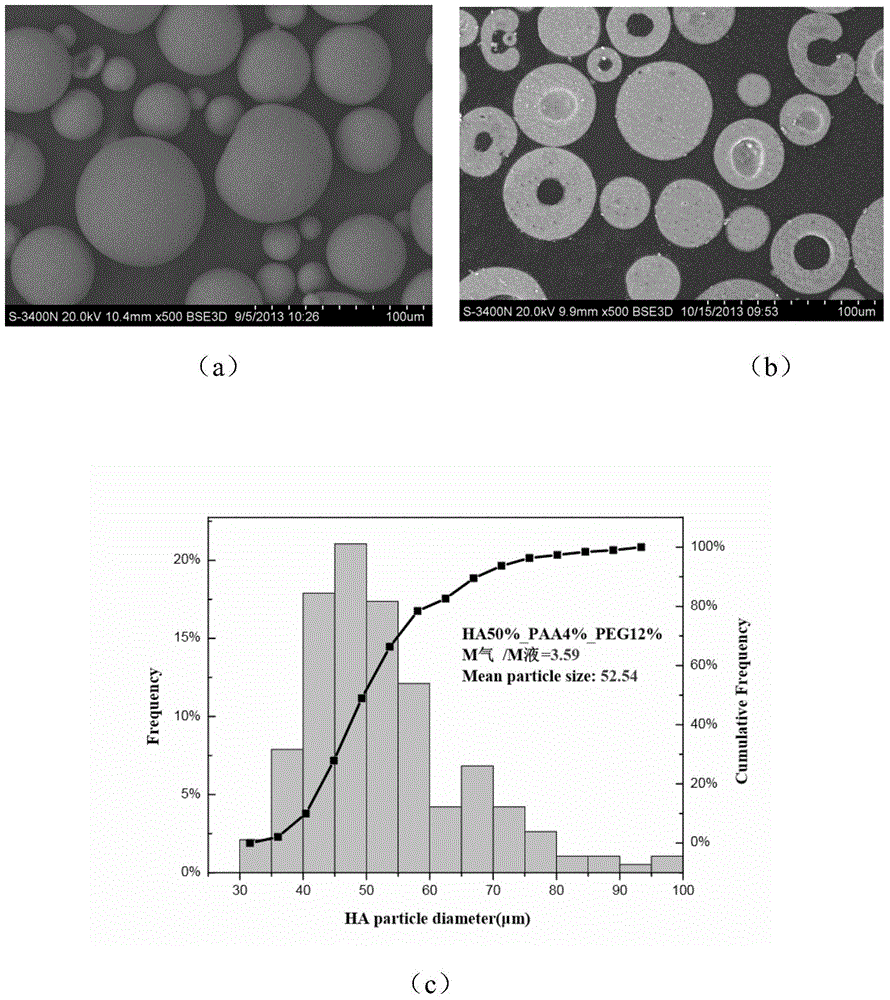

[0035] (1) Weigh 94g of deionized water and add it to the ball mill tank, add 10g of ammonium polyacrylate solution (concentration 40%), take 100g of nano-hydroxyapatite and mix it, prepare slurry (solid content 50%), ball mill for 5 hours, add 12g polyethylene glycol, continue ball milling for 5h;

[0036] (2) Spray-dry the uniformly mixed slurry, feed it under magnetic stirring, the nozzle diameter is 2mm, the inlet temperature is 170°C, the outlet temperature is 100°C, the feed rate is 13ml / min, the compressed air pressure 0.5MPa, compressed air flow rate is 1.5m 3 / h, M 气 / M 液 =6.67;

[0037] (3) Dry the powder obtained by spray drying at 80°C;

[0038] (4) Put the obtained powder in a resistance furnace (atmospheric atmosphere) for heat treatment, the heating rate is 5°C / min, first keep warm at 650°C for 3 hours, remove the organic additives in the powder, and continue heating to Keep warm at 950°C high temperature section for 2 hours, then cool to 500°C at a rate of...

Embodiment 3

[0041] (1) Weigh 94g of deionized water and add it to the ball mill tank, add 10g of ammonium polyacrylate solution (concentration 40%), take 100g of nano-hydroxyapatite and mix it, prepare slurry (solid content 40%), ball mill for 5 hours, add 6g polyethylene glycol, continue ball milling for 5h;

[0042] (2) Spray-dry the uniformly mixed slurry, feed it under magnetic stirring, the nozzle diameter is 2mm, the inlet temperature is 170°C, the outlet temperature is 100°C, the feed rate is 13ml / min, the compressed air pressure 0.5MPa, compressed air flow rate is 1.5m 3 / h, M 气 / M 液 =6.67;

[0043] (3) Dry the powder obtained by spray drying at 80°C;

[0044] (4) Put the obtained powder in a resistance furnace (atmospheric atmosphere) for heat treatment, the heating rate is 5°C / min, first keep warm at 650°C for 3 hours, remove the organic additives in the powder, and continue heating to 950°C high-temperature section for 1-2 hours, then cooled to 500°C at a rate of 10°C / min ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com