Preparation method for spherical cobaltosic oxide

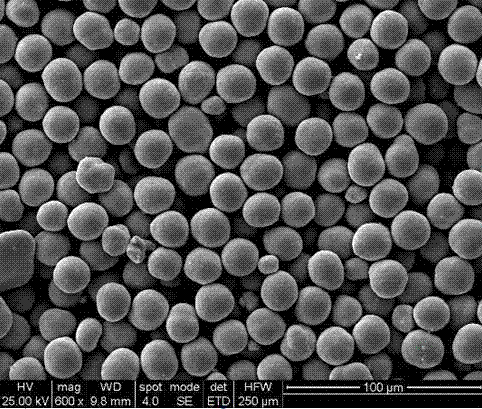

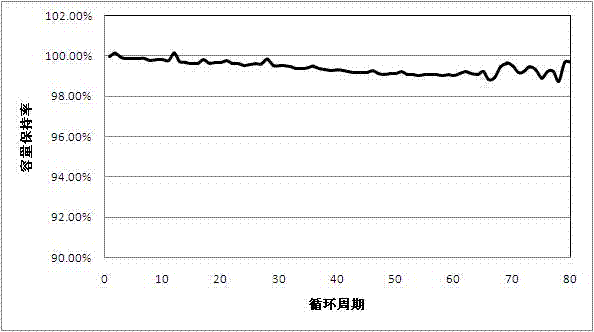

A technology of spherical cobalt tetroxide, which is applied in the field of preparation of spherical cobalt trioxide, can solve the problems of environmental pollution, high energy consumption, and difficulty in uniformly dispersing doping elements inside the lattice structure, etc., and achieves environmental friendliness, high density, and good sphericity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

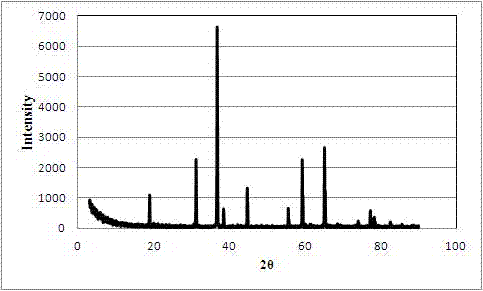

Embodiment 1

[0032] A kind of preparation method of spherical tricobalt tetroxide, by CoCl 2 : MgSO 4 : NbC 2 o 4 The molar ratio is 0.98:0.01:0.01, and a 3.3mol / L mixed liquid is prepared; the mixed liquid, 3mol / L LiOH solution, and 2mol / L NaClO solution are added to the reactor at a certain flow rate in parallel. =7.5 under the condition of stirring and reacting; then filtered and washed with pure water to obtain the intermediate product, which was calcined at 400°C for 20h to obtain (Co 0.98 Mg 0.01 Nb 0.01 ) 3 o 4 , measured D 50 =9.5um, AD=1.24g / cm 3 .

Embodiment 2

[0034] A kind of preparation method of spherical cobalt trioxide, by CoSO 4 :Al 2 (SO 4 ) 3 The molar ratio is 0.95:0.025, prepare 1mol / L mixed salt solution; mix the mixed solution with 2mol / L NH 4 OH solution and high-purity oxygen were added to the reactor at a certain flow rate, and the reaction was stirred at 40°C and pH=10.8; then filtered and washed with pure water to obtain an intermediate product, which was calcined at 600°C for 10 h to obtain (Co 0.95 Al 0.05 ) 3 o 4 , measured D 50 =20.5um, AD=1.43g / cm 3 .

Embodiment 3

[0036] A kind of preparation method of spherical tricobalt tetroxide, by Co (NO 3 )- 2 : Mn (NO 3 ) 2 : n-ZrO 2 The molar ratio is 0.96:0.02:0.02, prepare 2mol / L mixed liquid; put the mixed liquid, 6mol / L NaOH solution and compressed air into the reactor at a certain flow rate, and stir at 70°C and pH=8.0 reaction; then centrifuged, washed with pure water to obtain an intermediate product, and calcined at 800°C for 5h to obtain (Co 0.96 mn 0.02 Zr 0.02 ) 3 o 4 , measured D 50 =6.7um, AD=1.08g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| D50 | aaaaa | aaaaa |

| D50 | aaaaa | aaaaa |

| D50 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com