Self-phosphating waterborne polyurethane acrylate resin for axle and preparation method thereof

A technology of polyurethane acrylate and water-based polyurethane, applied in the field of polymer material preparation, can solve the problems of low degree of grafting and cross-linking of acrylate-polyurethane, insufficient degree of film-forming cross-linking, poor stability of emulsion, etc. Corrosion performance, improved emulsion and film performance, good flexibility and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

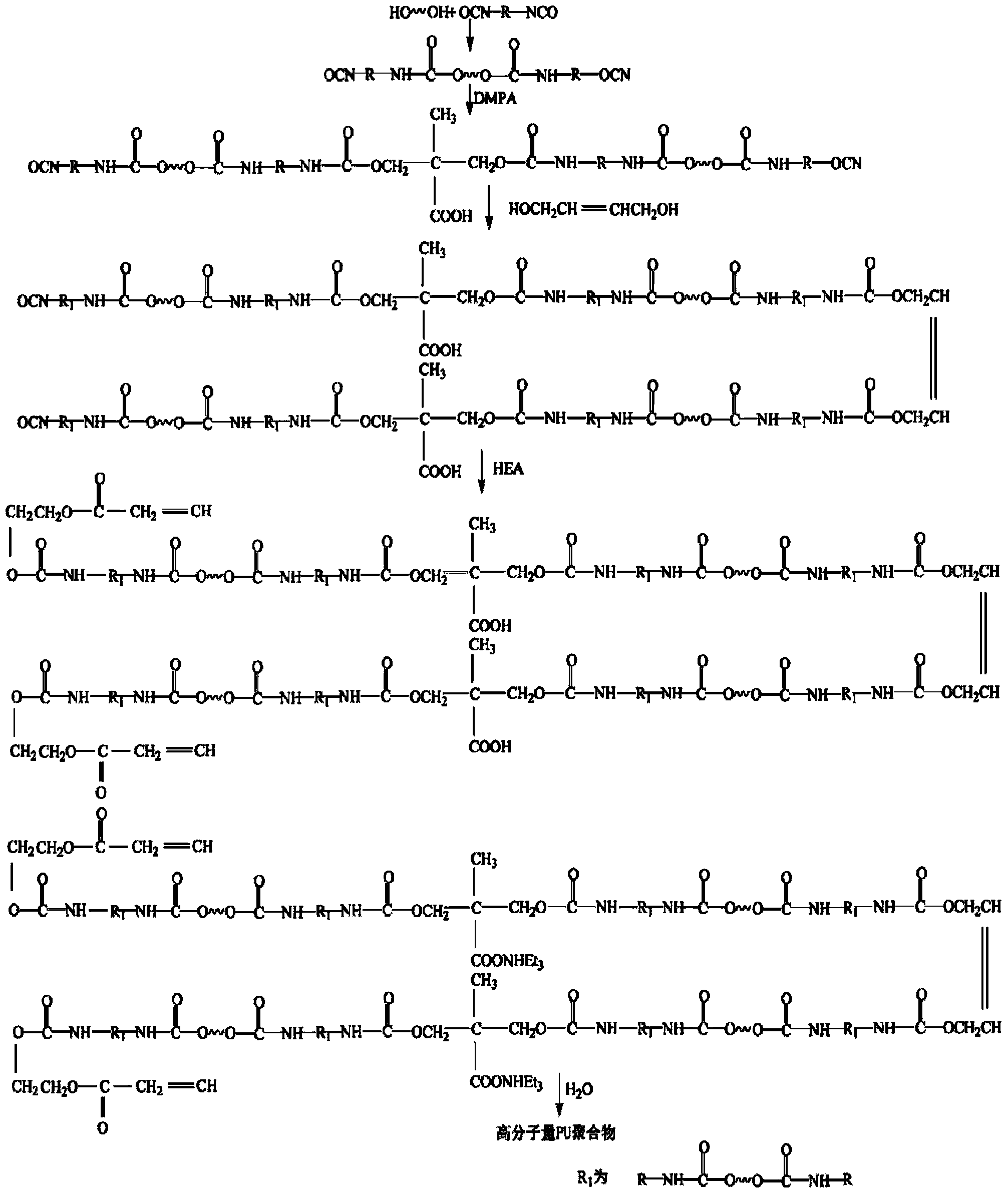

[0034] The preparation method of self-phosphating water-based polyurethane acrylate coating for vehicle axle, the steps are as follows:

[0035] 1) Carry out chain extension reaction with polyether diol, diisocyanate, dimethylol propionic acid (DMPA), 1,4-butene diol to obtain a water-based polyurethane prepolymer with terminal isocyanate groups; wherein,— The molar ratio of NCO to —OH is 1.3-1.8; the amount of dimethylolpropionic acid accounts for 4-7wt% of the water-based polyurethane prepolymer; the amount of the 1,4-butene glycol accounts for 1% of the water-based polyurethane prepolymer -4wt%; chain extension reaction temperature is 70-80°C, reaction time is 3-5h, and the viscosity of the system is adjusted with acetone;

[0036] 2) Add hydroxyethyl acrylate (HEA) to the isocyanate group-terminated polyurethane prepolymer to carry out the end-capping reaction, add triethylamine to neutralize the salt after cooling, add water to emulsify, and evaporate the solvent to obtai...

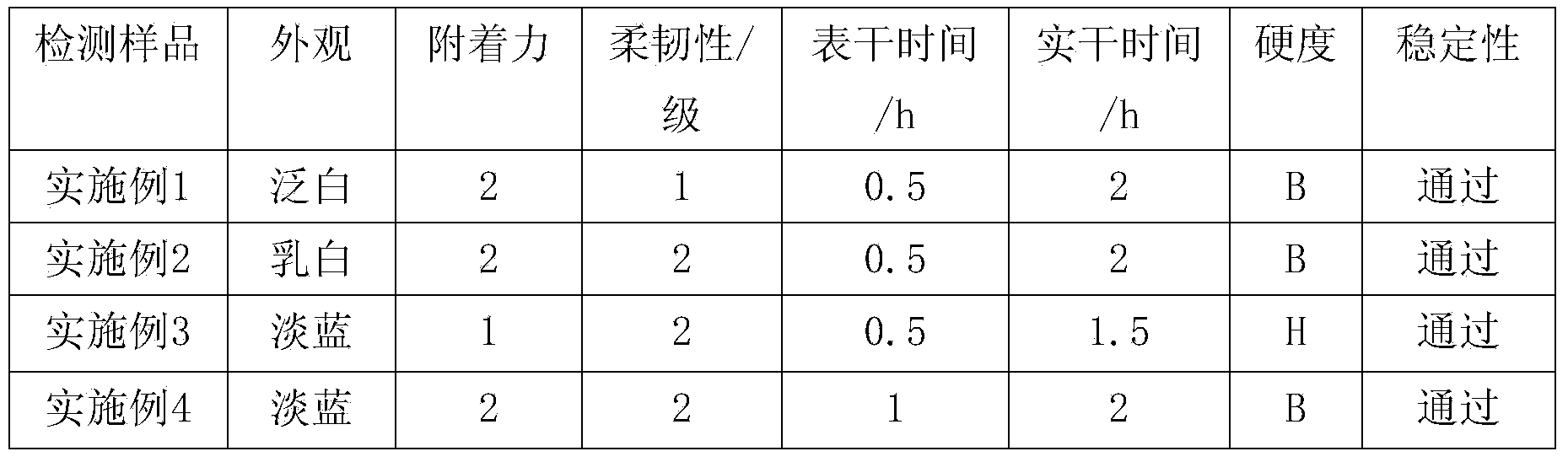

Embodiment 1

[0043]In the above synthesis chain extension process, the diisocyanate is selected from TDI; the molar ratio of —NCO to —OH is 1.3; the amount of dimethylol propionic acid accounts for 4wt% of the waterborne polyurethane prepolymer; the amount of 1,4-butene diol accounts for Prepolymer 1wt%; chain extension reaction temperature is 70°C, reaction time is 3h, during which acetone is used to adjust the viscosity of the system.

[0044] During the capping process, the dosage of hydroxyethyl acrylate was 5wt% of the water-based polyurethane prepolymer, the capping temperature was 70°C, and the capping reaction time was 1 h.

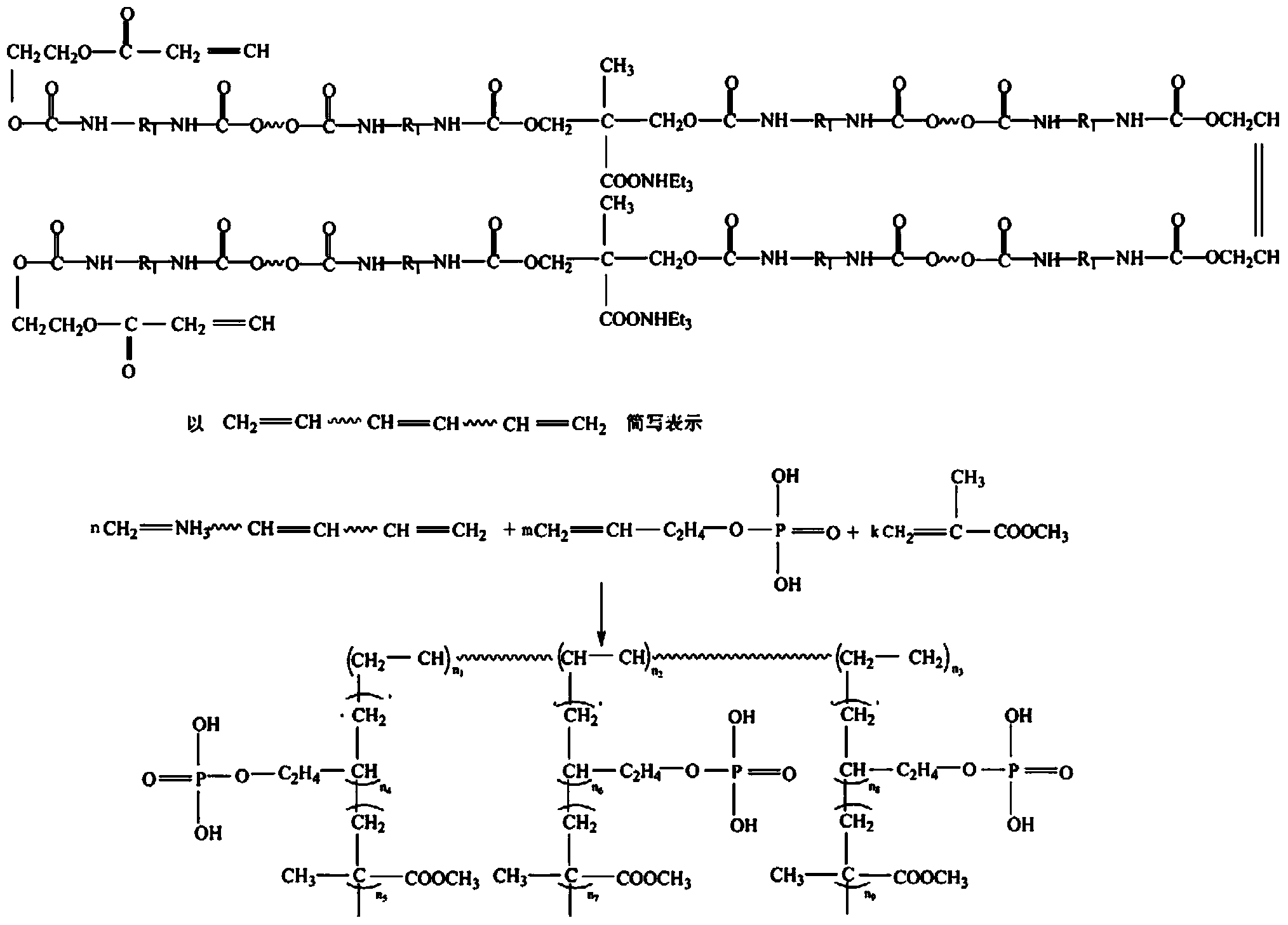

[0045] During the polymerization process, the polymerization reaction temperature was 78°C, the reaction time was 5h, and the amount of the mixed solution of initiator, PM-100 and MMA was 20wt% of the waterborne polyurethane prepolymer; among them, the amount of PM-100 was the waterborne polyurethane prepolymer of 5wt%.

[0046] The finally obtained aqueous s...

Embodiment 2

[0048] In the above-mentioned synthetic chain extension process, the diisocyanate is selected from TDI; the molar ratio of —NCO to —OH is 1.8; the amount of dimethylol propionic acid accounts for 7wt% of the water-based polyurethane prepolymer; the 1,4-butene The amount of diol accounted for 4wt% of the waterborne polyurethane prepolymer; the chain extension reaction temperature was 80°C, and the reaction time was 5h, during which acetone was used to adjust the viscosity of the system.

[0049] During the capping process, the dosage of hydroxyethyl acrylate was 10wt% of the waterborne polyurethane prepolymer, the capping temperature was 70°C, and the capping reaction time was 1 h.

[0050] During the polymerization process, the polymerization reaction temperature was 90°C, the reaction time was 5h, and the amount of the mixed solution of initiator, PM-100 and ethyl acrylate was 30wt% of the waterborne polyurethane prepolymer; among them, the amount of PM-100 was the waterborne ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com