Filling pipe with a leak alarm function

A fueling pipe and function technology, applied in the field of fueling pipes with leakage alarm function, can solve the problems of insufficient fuel filling, narrow interior space of the car, troublesome connection of the fueling port, etc. The effect of stone resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

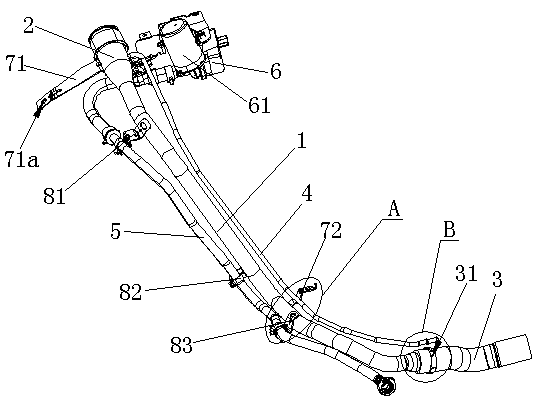

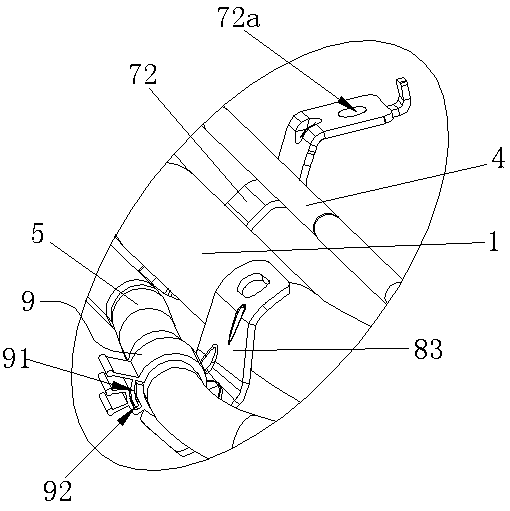

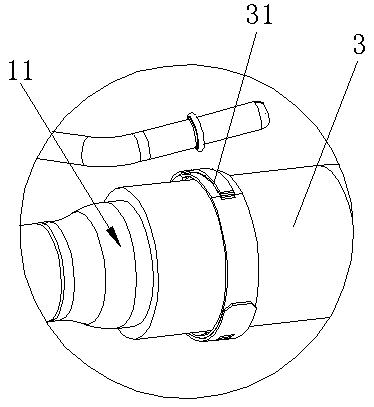

[0024] Such as Figure 1 to Figure 5 Shown is the structural representation of the present invention,

[0025] The reference signs in it are: oil filling pipe body 1, electroplated color zinc layer 1a, PE powder layer 1b, diameter expanding section 11, oil filling port 2, guide pipe 21, oil filling hose 3, single-ear stepless clamp 31, ventilation pipe 4 , air return pipe 5, mounting bracket 6, DMTL leak detection valve 61, first fixing bracket 71, first fixing hole 71a, second fixing bracket 72, second fixing hole 72a, first connecting bracket 81, second connecting bracket 82 , the third connecting bracket 83 , the fixed pipe clip 9 , the bump 91 , and the slot 92 .

[0026] Such as Figure 1 to Figure 5 as shown,

[0027] A filling pipe with a leakage alarm function, comprising a filling pipe body 1 and a filling port 2, a filling rubber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com