Preparation method of bismuth sodium titanate-barium titanate lead-free composite piezoelectric thick film

A technology of sodium bismuth titanate and barium titanate, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., can solve the incompatibility of semiconductor preparation processes , complex aerosol deposition process, affecting film quality and other issues, to achieve the effect of increasing thickness, increasing density, and increasing deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A preparation method of bismuth sodium titanate-barium titanate lead-free composite piezoelectric thick film includes the following steps:

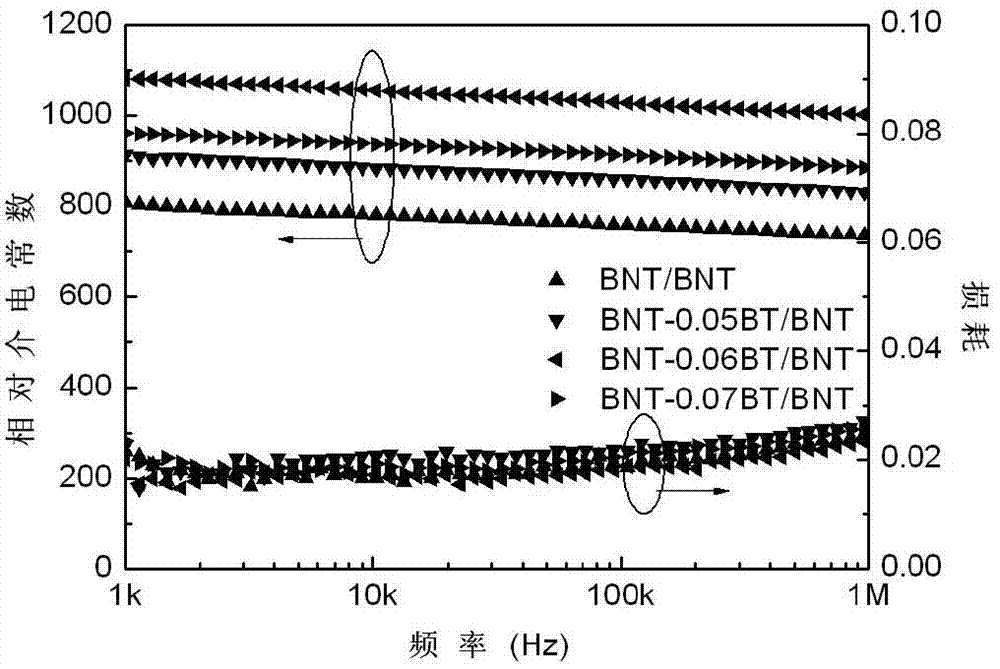

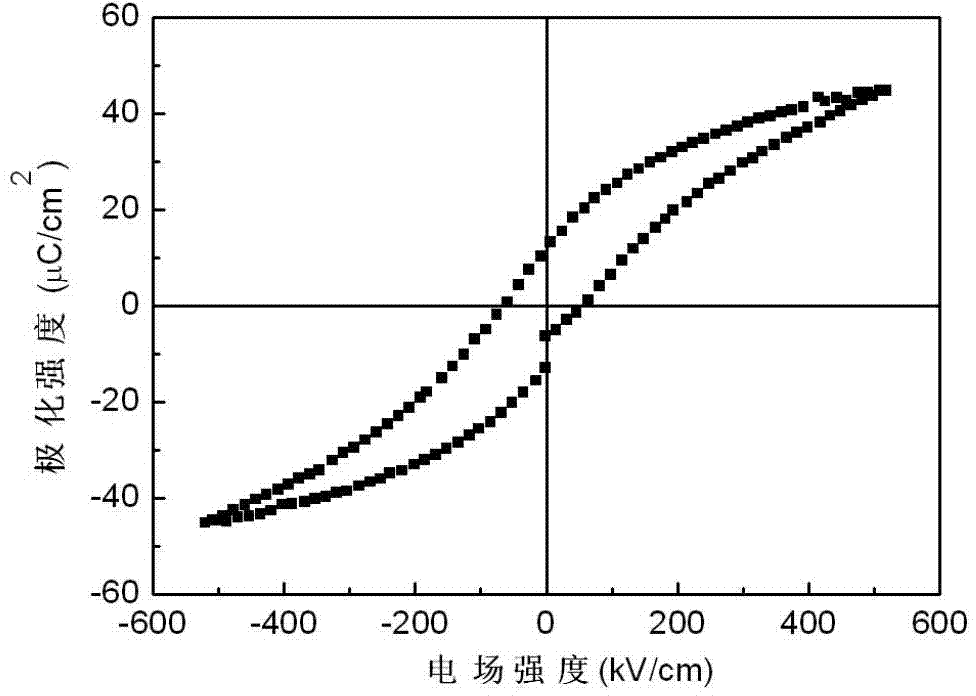

[0048] 1) According to (1-x)Bi 0.5 Na 0.5 TiO 3 -xBaTiO 3 (Where x=0,0.05,0.06,0.07) the stoichiometric ratio, using barium carbonate, sodium carbonate, titanium dioxide and bismuth oxide as raw materials, mixed wet milling for 7 hours, and dried at 80°C for 6 hours to obtain a uniformly mixed raw material , And then compressed with a diameter of 45mm, and sintered at 800 ℃ for 4 hours to obtain bismuth sodium titanate-barium titanate with perovskite structure (abbreviated as BNT, BNT-0.05BT, BNT-0.06BT, BNT-0.07 BT) The blanks, which are respectively subjected to ordinary planetary ball milling for 7 hours, to obtain micro-nano-level BNT, BNT-0.05BT, BNT-0.06BT, and BNT-0.07BT powders;

[0049] 2) According to Bi 0.5 Na 0.5 TiO 3 Add tetra-n-butyl titanate solution and sodium acetate solution dropwise to the bismuth nitrate solution an...

Embodiment 2

[0056] A preparation method of bismuth sodium titanate-barium titanate lead-free composite piezoelectric thick film includes the following steps:

[0057] 1) According to (1-x)Bi 0.5 Na 0.5 TiO 3 -xBaTiO 3 (Where x=0,0.05,0.06,0.07) the stoichiometric ratio, using barium carbonate, sodium carbonate, titanium dioxide and bismuth oxide as raw materials, mixed wet milling for 7 hours, and dried at 80°C for 6 hours to obtain a uniformly mixed raw material , And then compressed with a diameter of 45mm, and sintered at 800 ℃ for 4 hours to obtain bismuth sodium titanate-barium titanate with perovskite structure (abbreviated as BNT, BNT-0.05BT, BNT-0.06BT, BNT-0.07 BT) The blanks, which are respectively subjected to ordinary planetary ball milling for 7 hours, to obtain micro-nano-level BNT, BNT-0.05BT, BNT-0.06BT, and BNT-0.07BT powders;

[0058] 2) According to Bi 0.5 Na 0.5 TiO 3 The stoichiometric ratio of tetra-n-butyl titanate and sodium acetate solution were added dropwise to the b...

Embodiment 3

[0065] A preparation method of bismuth sodium titanate-barium titanate lead-free composite piezoelectric thick film includes the following steps:

[0066] 1) According to (1-x)Bi 0.5 Na 0.5 TiO 3 -xBaTiO 3 (Where x=0,0.05,0.06,0.07) the stoichiometric ratio, using barium carbonate, sodium carbonate, titanium dioxide and bismuth oxide as raw materials, mixed wet milling for 7 hours, and dried at 80°C for 6 hours to obtain a uniformly mixed raw material , And then compressed with a diameter of 45mm, and sintered at 800 ℃ for 4 hours to obtain bismuth sodium titanate-barium titanate with perovskite structure (abbreviated as BNT, BNT-0.05BT, BNT-0.06BT, BNT-0.07 BT) The blanks, which are respectively subjected to ordinary planetary ball milling for 7 hours, to obtain micro-nano-level BNT, BNT-0.05BT, BNT-0.06BT, and BNT-0.07BT powders;

[0067] 2) According to Bi 0.5 Na 0.5 TiO 3 The stoichiometric ratio of tetra-n-butyl titanate and sodium acetate solution were added dropwise to the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com