Copper chromite black pigment, and preparation method and application thereof

A technology of copper chrome black and pigment, applied in the direction of chromium oxide/hydrate, etc., can solve the problems of poor coloring ability, large particle size, uneven particle size distribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

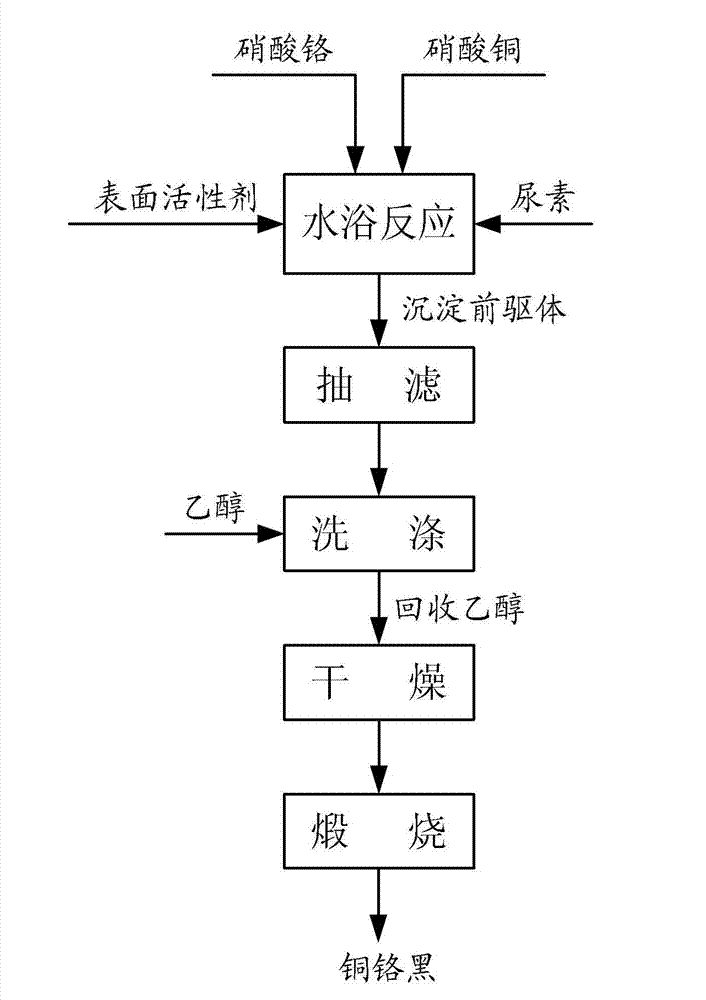

[0068] A kind of preparation method of copper chrome black pigment:

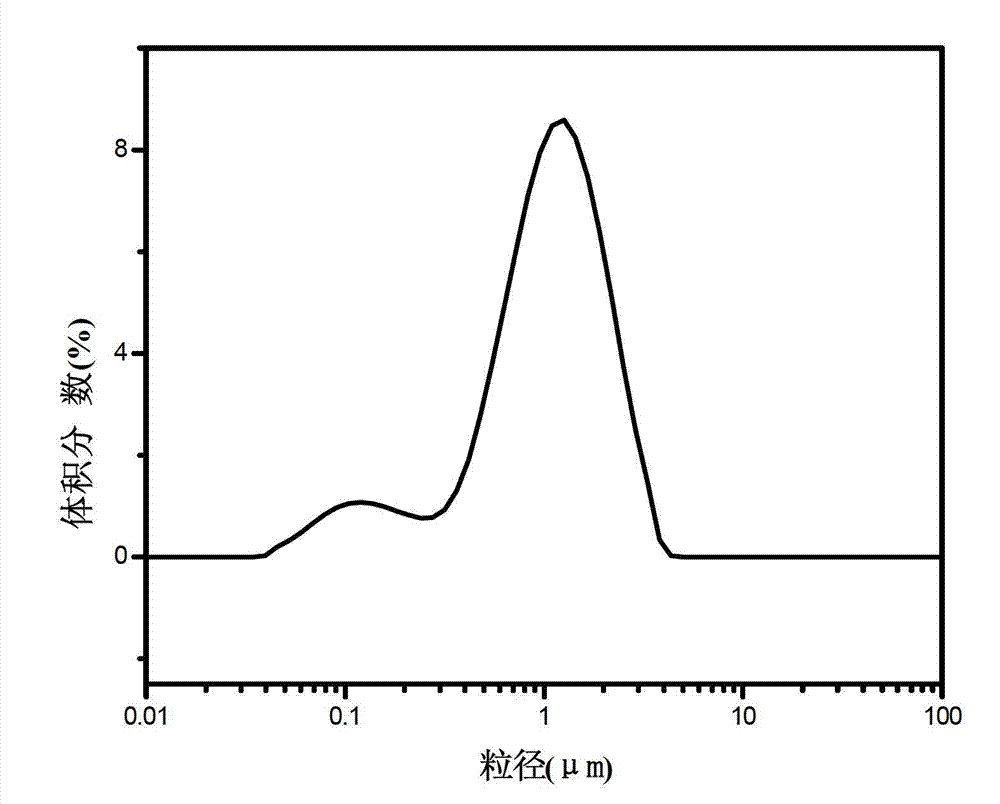

[0069] 2.4969g of copper sulfate pentahydrate, 8.003g of chromium nitrate nonahydrate, prepared as a mixed solution, moved to a 250ml three-necked flask, added 0.4874g of emulsifier OP-10, and 9.6096g of urea to prepare a solution, and slowly added the urea solution dropwise into the flask . Under normal pressure, react at 20°C, and end at pH=9. After the reaction, filter, wash with ethanol, and dry to obtain a light blue powder, and keep the precursor at 800°C for 1.5 hours to obtain a copper chromium black pigment. The average particle diameter of the copper chromium black pigment obtained in the present invention is 1.46 μm; the ultraviolet light reflectance at 600 nm is 31.3% when the dilution ratio is 1:10, which is 2.9% lower than that of the prior art.

Embodiment 2

[0071] A kind of preparation method of copper chrome black pigment:

[0072] Copper sulfate pentahydrate 3.7454g, chromium nitrate nonahydrate 12.0045g, prepared as a mixed solution, moved to a 250ml three-neck flask, added polyethylene glycol 400 0.8123g, urea 12.012g to prepare a solution, and slowly added the urea solution dropwise into the flask . Under normal pressure, react at 98°C and end at pH=5. After the reaction, filter, wash with ethanol, and dry to obtain a light blue powder, and keep the precursor at 900°C for 3 hours to obtain a copper chromium black pigment. The average particle diameter of the copper chrome black pigment obtained in the present invention is 0.10 μm; the ultraviolet light reflectance at 600 nm is 31.493% when the dilution ratio is 1:10, which is 2.3% lower than that of the prior art.

Embodiment 3

[0074] A kind of preparation method of copper chrome black pigment:

[0075] The experimental procedure is the same as in Example 1, and the reaction conditions are as follows: 1.2485g of copper sulfate pentahydrate, 4.0015g of chromium nitrate nonahydrate, 0.8952g of sodium dodecylbenzenesulfonate, 9.6096g of urea, under normal pressure, 95°C, 700°C Keep warm for 4h. The average particle size of the copper chrome black pigment obtained in the present invention is 1.95 μm; the ultraviolet light reflectance at 600 nm is 29.656% when the dilution ratio is 1:10, which is 8.0% lower than that of the prior art.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com