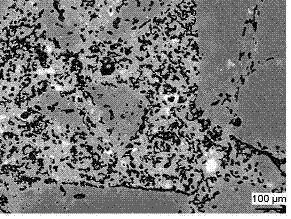

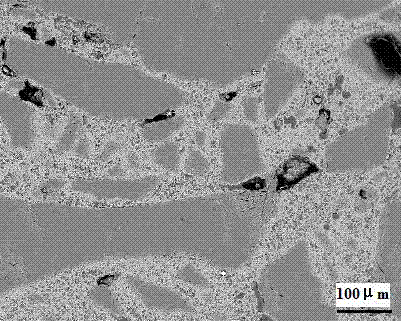

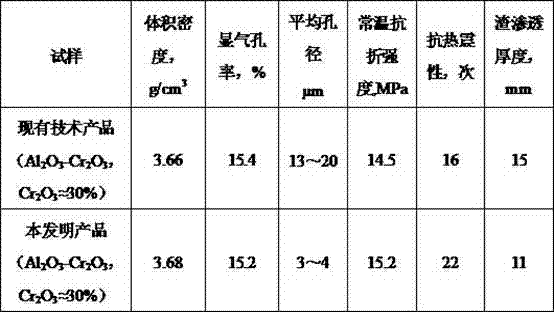

Al2O3-Cr2O3 refractory material having microporous structure

A technology of al2o3-cr2o3 and refractory materials, applied in the field of refractory materials, can solve problems such as uneven pore size distribution, achieve excellent thermal shock resistance, excellent slag erosion resistance, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh D separately 50 6μm chromium oxide green powder (Cr 2 o 3 ≥99%) 6kg, D 50 5μm alumina powder (Al 2 o 3 ≥99%) 4kg, sodium hexametaphosphate 120g, cellulose 160g, prepared into a slurry with a solid content of 65%, spray granulation. Weigh the fused chromium oxide (Cr 2 o 3 ≥99%) 2.2kg, sintered alumina (Al 2 o 3 ≥99%) 0.5kg, Al prepared in the previous step 2 o 3 -Cr 2 o 3 Granulation material 1kg, ZrO 2 0.3kg of fine powder is fully premixed by a ball mill to prepare a matrix. Sintered corundum particles (Al 2 o 3≥99%) 0.5kg, particle size 1mm~3mm fused Al 2 o 3 -Cr 2 o 3 Particles (Cr 2 o 3 ≈50%) 4kg, fused chromium oxide particles (Cr 2 o 3 ≥99%) 1.5kg into the roller sand mixer and mix evenly, add 0.3kg of PVA aqueous solution with a mass fraction of 5% to the granular material, add the premixed matrix fine powder after stirring, and mix well, the trapped material , friction brick press forming body, after drying at 60°C, put it into a s...

Embodiment 2

[0030] Weigh D separately 50 10μm chromium oxide green powder (Cr 2 o 3 ≥99%) 2kg, D 50 3μm alumina powder (Al 2 o 3 ≥99%) 8kg, ammonium hexametaphosphate 50g, dextrin 300g, prepared into a slurry with a solid content of 55%, spray granulation. Weigh the sintered chromium oxide (Cr 2 o 3 ≥99%) 1kg, sintered alumina (Al 2 o 3 ≥99%) 1.8kg, Al prepared in the previous step 2 o 3 -Cr 2 o 3 Granulation material 1kg, Y 2 o 3 0.2kg of fine powder is fully pre-mixed by a ball mill to prepare a matrix. Sintered corundum particles (Al 2 o 3 ≥99%) 3.5kg, particle size 1mm~3mm fused Al 2 o 3 -Cr 2 o 3 Particles (Cr 2 o 3 ≈70%) 1kg, sintered chromium oxide particles (Cr 2 o 3 ≥99%) 1.5kg into the roller sand mixer and mix evenly, add 0.3kg of PVA aqueous solution with a mass fraction of 5% to the granular material, add the premixed matrix fine powder after stirring, and mix well, the trapped material ; After the green body is formed by a friction brick press, it is...

Embodiment 3

[0032] Weigh D separately 50 8μm chromium oxide green powder (Cr 2 o 3 ≥99%) 4kg, D 50 4μm alumina powder (Al 2 o 3 ≥99%) 6kg, polyacrylamide 90g, cellulose 260g, prepared into a slurry with a solid content of 75%, spray granulation. Weigh the sintered chromium oxide (Cr 2 o 3 ≥99%) 1kg, fused alumina (Al 2 o 3 ≥99%) 1kg, Al prepared in the previous step 2 o 3 -Cr 2 o 3 1.5 kg of granulated material and 0.5 kg of MgO micropowder are fully premixed by a ball mill to prepare a matrix. Weigh the fused corundum particles (Al 2 o 3 ≥99%) 1kg, particle size 1mm~3mm fused Al 2 o 3 -Cr 2 o 3 Particles (Cr 2 o 3 ≈80%) 1kg, sintered chromium oxide particles (Cr 2 o 3 ≥99%) 4kg was added to the roller sand mixer and mixed evenly, and 0.3kg of calcium lignosulfonate solution with a mass concentration of 35% was added to the pellets, and after stirring, the premixed matrix fine powder was added. material; the body formed by a friction brick press, dried at 110°C, put...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com