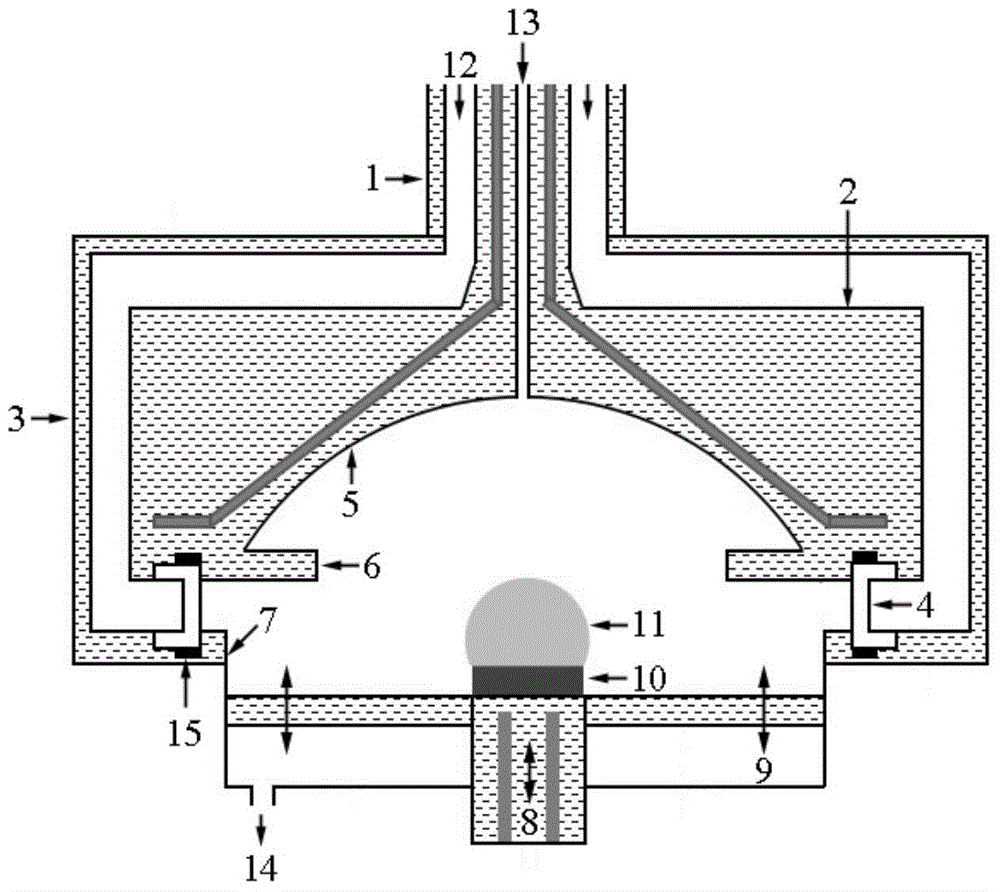

A dome-type microwave plasma chemical vapor deposition diamond film device

A technology of microwave plasma and chemical vapor deposition, which is applied in the direction of gaseous chemical plating, electrical components, metal material coating technology, etc., to achieve the effect of uniform deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

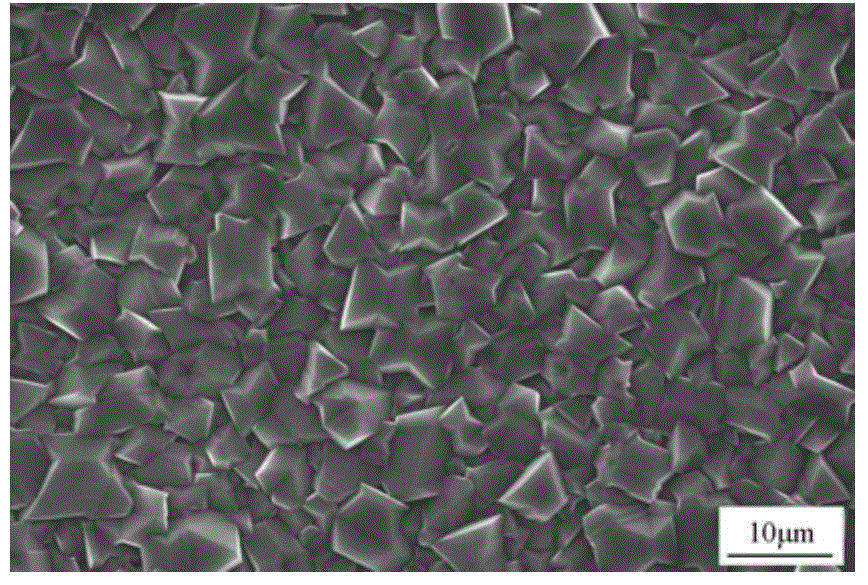

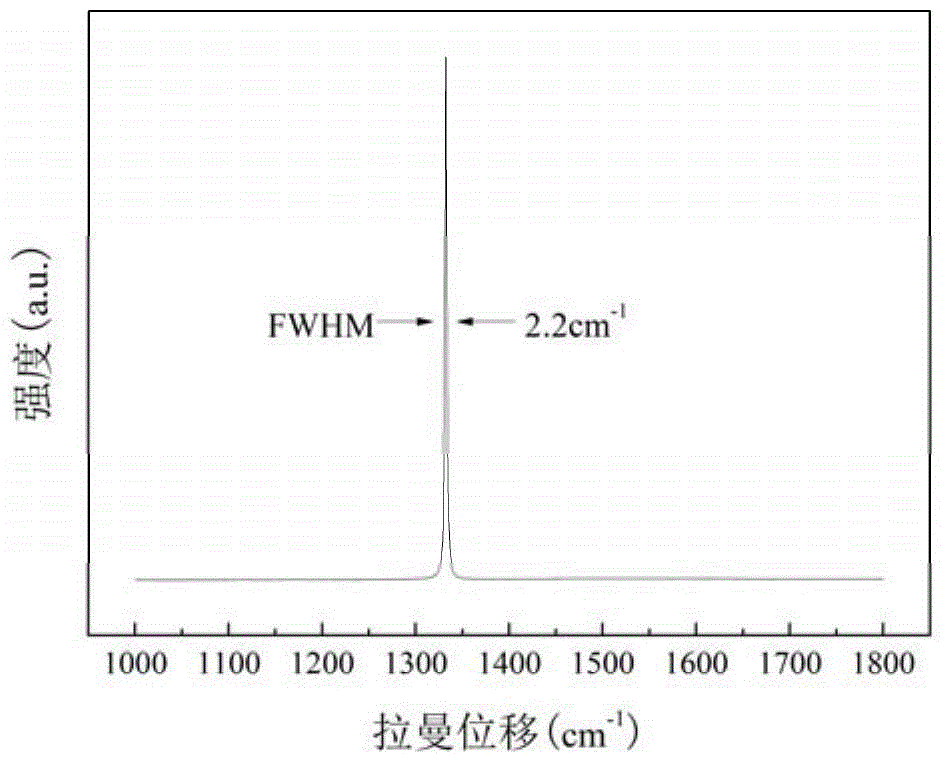

[0031] Utilize the dome type MPCVD diamond film deposition device that the present invention proposes, carried out the deposition of high-quality diamond film, experimental process is as follows:

[0032] (1) Turn on the chiller, from the top coaxial waveguide converter 1 to the middle cylindrical loop antenna 2 to the bottom adjustable center deposition table 8 and adjustable edge deposition table 9, and the entire cylindrical shell 3, All parts through which the microwave propagates are water-cooled;

[0033] (2) Turn on the mechanical pump to evacuate the resonance cavity to below 1Pa;

[0034] (3) The hydrogen gas and the methane gas with a flow rate of 400ml / min and 20ml / min are respectively introduced into the resonance cavity through the intake pipe 13;

[0035] (4) Adjust the valve size of the mechanical pump so that the gas pressure in the resonance chamber is around 800Pa;

[0036] (5) Turn on the microwave power supply, input the microwave 12 with a frequency of 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com