Method for reducing inner residual stress of nickel-based superalloy

A technology of nickel-based superalloys and internal residual stress, which is applied in the field of nickel-based superalloys to reduce the internal residual stress of nickel-based superalloys, can solve the problems of reducing material performance, safety hazards, stress corrosion, etc., and achieve material dimensional stability Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1: Cold and hot cycle treatment scheme and dimensional stability improvement effect of CMSX4 nickel-based superalloy

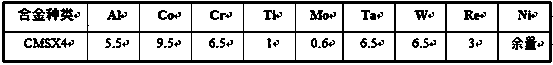

[0017] Table 1 Composition list of high temperature nickel-based alloy CMSX4

[0018]

[0019] In vacuum smelting, the CMSX4 nickel-based alloy was smelted according to the above composition ratio, and it was formed by investment casting; the alloy was subjected to solution treatment at 1312°C for 6 hours, and then air-cooled to room temperature after heat treatment.

[0020] The cold and hot cycle treatment process is:

[0021] The cooling rate during cold treatment is 5°C / min;

[0022] Low temperature treatment temperature is -150°C;

[0023] Holding time 24h;

[0024] Set the temperature at 200°C for 22 hours during the warm-up treatment;

[0025] The number of heating and cooling cycles is 2;

[0026] After the above cold and heat cycle treatment, the dimensional stability of CMSX4 increased by 40%.

Embodiment 2

[0027] Example 2: Cold and hot cycle treatment scheme and dimensional stability improvement effect of CMSX10N nickel-based superalloy

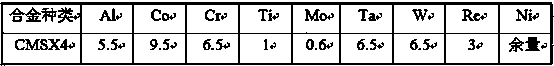

[0028] Table 2 Composition list of nickel-based superalloy CMSX10N

[0029]

[0030] In vacuum melting, the CMSX10N nickel-based alloy was smelted according to the above composition ratio, and it was formed by investment casting; the alloy was subjected to solid solution treatment at 1360°C for 24 hours, and air-cooled to room temperature after heat treatment.

[0031] The cold and hot cycle treatment process is:

[0032] The cooling rate during cold treatment is 15°C / min;

[0033] Low temperature treatment temperature is -175°C;

[0034] Holding time 36h;

[0035] Set the temperature at 250°C for 18 hours during the warm-up treatment;

[0036] The number of heating and cooling cycles is 2;

[0037] After the above cold and heat cycle treatment, the dimensional stability of CMSX4 increased by 45%.

Embodiment 3

[0038] Embodiment three: Udmet 500 Cold and hot cycle treatment scheme and dimensional stability improvement effect of nickel-based superalloy

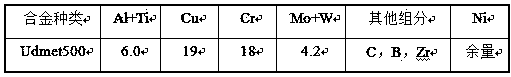

[0039] Table 3 Composition list of Udmet500 nickel-based superalloy

[0040]

[0041] In vacuum melting, Udmet500 nickel-based alloy is smelted according to the above composition ratio, and it is formed by investment casting; the alloy is subjected to four-stage solution aging treatment, specifically: solution treatment, 1175 ° C, 2 hours, air cooling; intermediate treatment , 1080°C, 4 hours, air-cooled; primary aging treatment, 843°C, 24 hours, air-cooled; secondary aging treatment, 760°C, 16 hours, air-cooled.

[0042] Air-cool to room temperature after heat treatment; cold and heat cycle treatment process is:

[0043] The cooling rate during cold treatment is 20°C / min;

[0044] Low temperature treatment temperature is -196°C;

[0045] Holding time 48h;

[0046] Set the temperature at 755°C for 24 hours during the warm-u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com