Hard alloy for low-load high-speed punching precision mold and preparation method thereof

A high-speed stamping and precision mold technology, applied in the field of cemented carbide, can solve problems affecting the quality of stamped parts, poor wear resistance of parts, micro-cracking, etc., and achieve excellent chemical corrosion resistance, long service life, and high hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

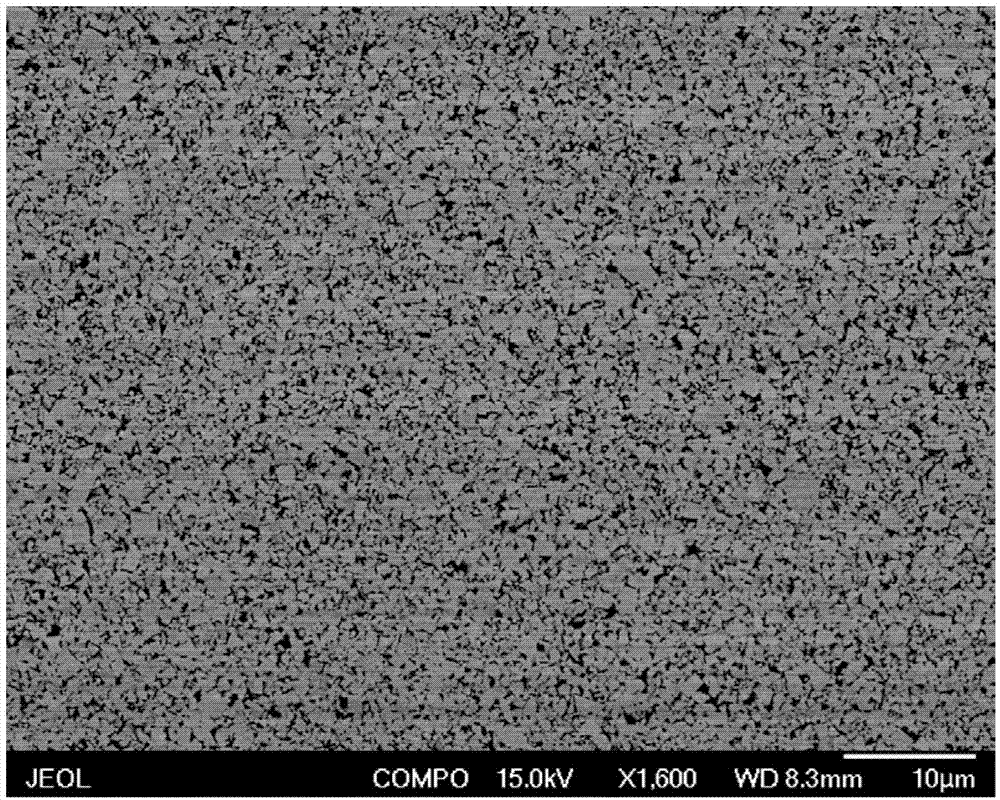

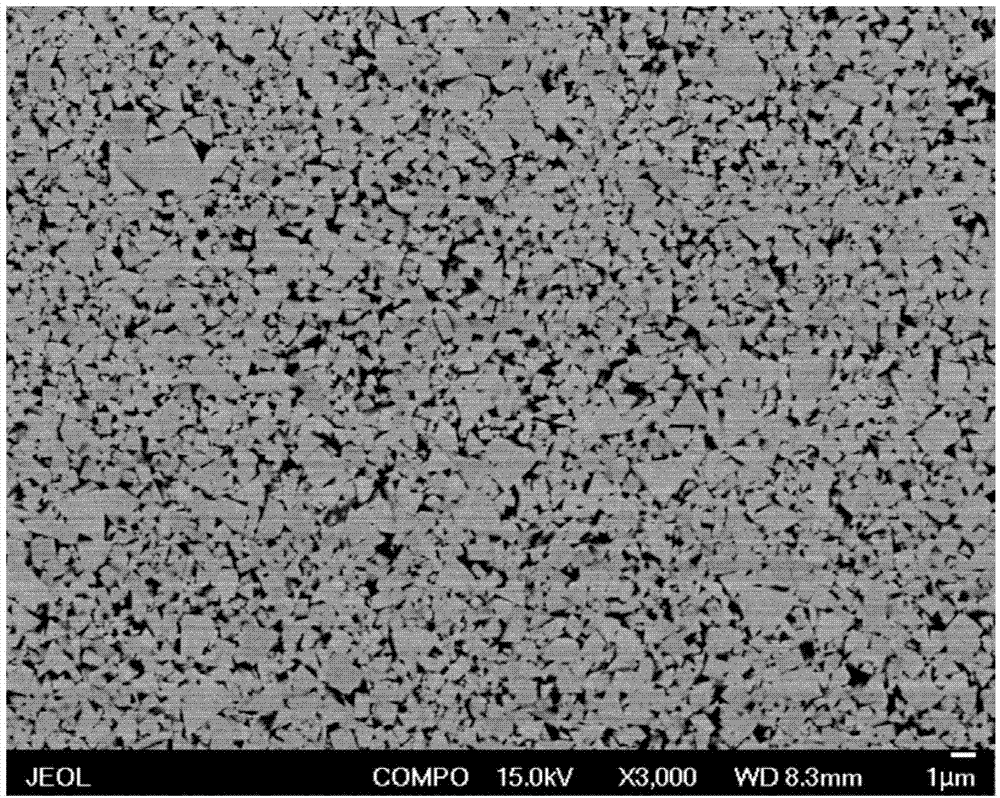

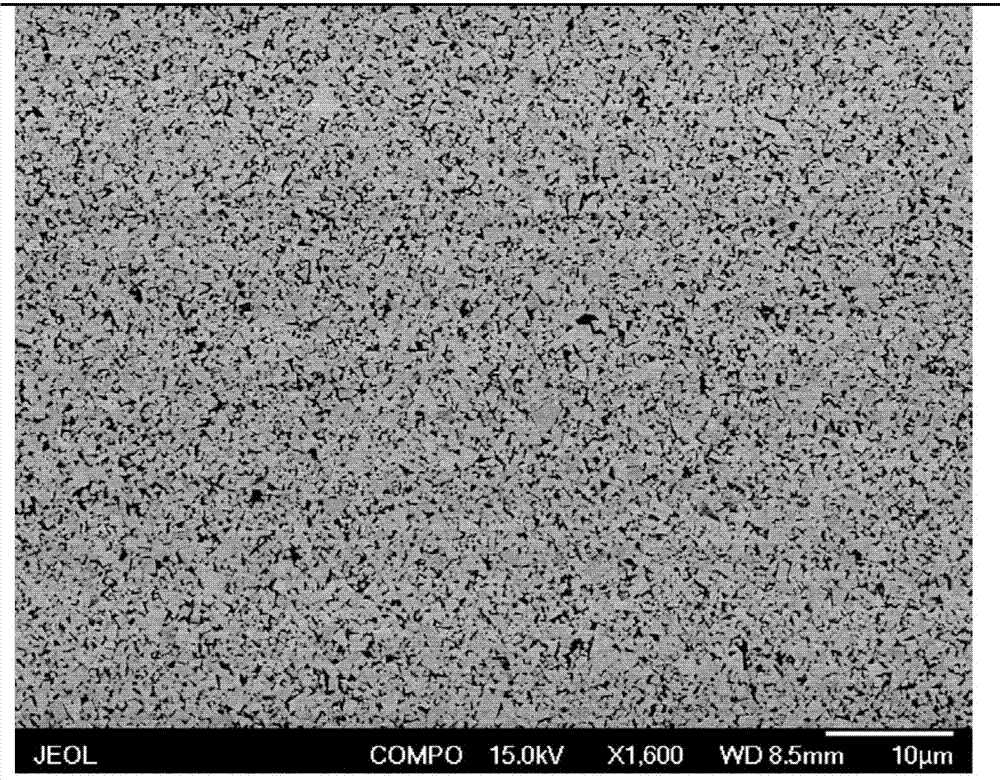

Image

Examples

Embodiment 1

[0029] Embodiment 1: Carbide of the present invention according to the following steps:

[0030] (1) Equipped with raw materials: 100% based on the total weight of raw materials, fine-grained WC with a mass percentage of 63.49% and a Fischer particle size of 0.9μm, a mass percentage of 5.67% of Co powder, and a mass percentage of Ni powder of 2.83% , the mass percentage is 0.8% Cr 3 C 2 , with a mass percentage of 27.21% and coarse-grained WC with a Fischer particle size of 1.9 μm; the actual total carbon content of the above raw materials is 5.69% (fine-grained WC3.90%+Cr 3 C 2 0.11%+coarse grain WC1.68%);

[0031] (2) Adding C / W: the correction value of the total alloy carbon balance is 0.03%, and the total alloy carbon correction amount = the actual total carbon content of the raw material is 5.69% - the theoretical total carbon content of the alloy in this example is 5.67% - the total carbon balance of the alloy Correction value 0.03%=-0.01%, this value is a negative n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com