Mesotrione oil dispersion and preparation method thereof

The technology of mesotrione and suspending agent is applied in the field of selective post-emergence stem and leaf treatment herbicide in corn field and its preparation field, which can solve the problem that secondary pollution of dust cannot be completely avoided, the viscosity of suspending agent is difficult to control, and it is inconvenient to use, etc. problems, to achieve the effect of stable and reliable product quality, qualified physical and chemical stability, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

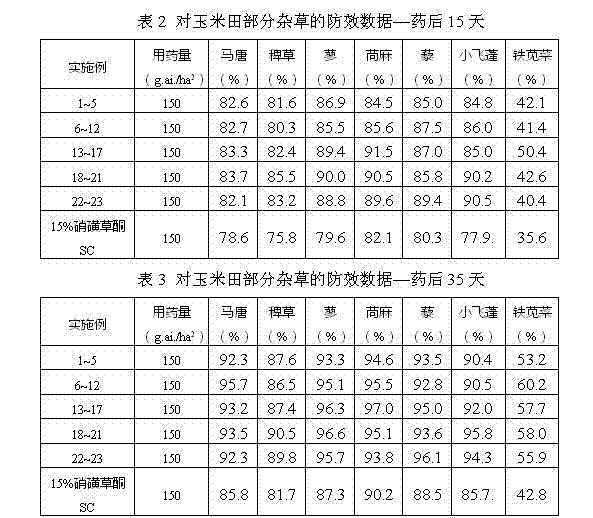

[0019] First add 10% castor oil polyoxyethylene ether, 5% comb-shaped saturated monomer copolymerized polymer compound, the remaining 71.47% methyl oleate, and 1% fatty alcohol ethoxyglyceride into the reaction kettle, and use Under the action of a high-speed shearing machine at a speed of 1500-12000 rpm, it is mixed into a liquid phase, and then 10.53% (10% converted to 10%) of the original drug of mesotrione with a purity of 95% and 1% organic bentonite , 1% white carbon black and other solid raw materials were added to the reaction kettle and mixed with the liquid phase in the first step together with a high-speed shearing machine for 10 to 20 minutes and mixed into a suspension; then the suspension was sent to the sand Grind into a dispersible oil-suspending agent in a mill. After grinding for 2 hours, the detection fineness reaches 5 to 10 microns, and the material is filtered out, and the quality indicators of the inspection are up to the quality standards of the dispersi...

Embodiment 2

[0021] First add 6% soybean oil polyoxyethylene ether, 3% fatty alcohol polyoxyethylene ether phosphate, 8% polyester polymer mixture, the remaining 65.47% methylated rapeseed oil, and 5% acetic acid into the reaction kettle , with a high-speed shearing machine at a speed of 1500 to 12000 rpm, mix it into a liquid phase, and then mix 10.53% (10% percent) of the original drug of mesotrione with a purity of 95%, 2% Organic bentonite and other solid raw materials are added to the reaction kettle and mixed with the liquid phase in the first step, and are mixed with a high-speed shear for 10 to 20 minutes to form a suspension; then the suspension is sent to a sand mill for grinding into a dispersible oil suspension, after grinding for 2 hours, the detection fineness reaches 5 to 10 microns, and the material is filtered out, and every quality index of the inspection reaches the quality standard of the dispersible oil suspension, that is, the described mesotrione is obtained Dispersi...

Embodiment 3

[0023] First add 5% calcium dodecylbenzenesulfonate, 3% fatty alcohol polyoxyethylene ether phosphate, 10% polyoxyethylene-polyoxypropylene block polyether, the balance 66.47% turpentine, and 3% lactic acid to the In the reaction kettle, use a high-speed shearing machine at a speed of 1500 to 12000 rpm to mix it into a liquid phase, and then add 10.53% (10% to 10%) of the original drug of mesotrione with a purity of 95% , 2% organic bentonite and other solid raw materials were added to the reaction kettle and mixed with the liquid phase in the first step together with a high-speed shearing machine for 10 to 20 minutes and mixed into a suspension; then the suspension was sent to the sand mill Grind into a dispersible oil suspension in the machine. After grinding for 2 hours, the detection fineness reaches 5 to 10 microns, and the material is filtered out. The quality indicators of the inspection are up to the quality standard of the dispersible oil suspension, and the nitrate is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com