Polylactic acid/core-shell structure composite material and preparation method thereof

A composite material, polylactic acid technology, applied in the field of polylactic acid/core-shell composite material and its preparation, can solve the problems of high strength and modulus loss, little increase in toughness, poor weather resistance, etc., to save time and Cost, excellent mechanical properties, and the effect of reducing dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

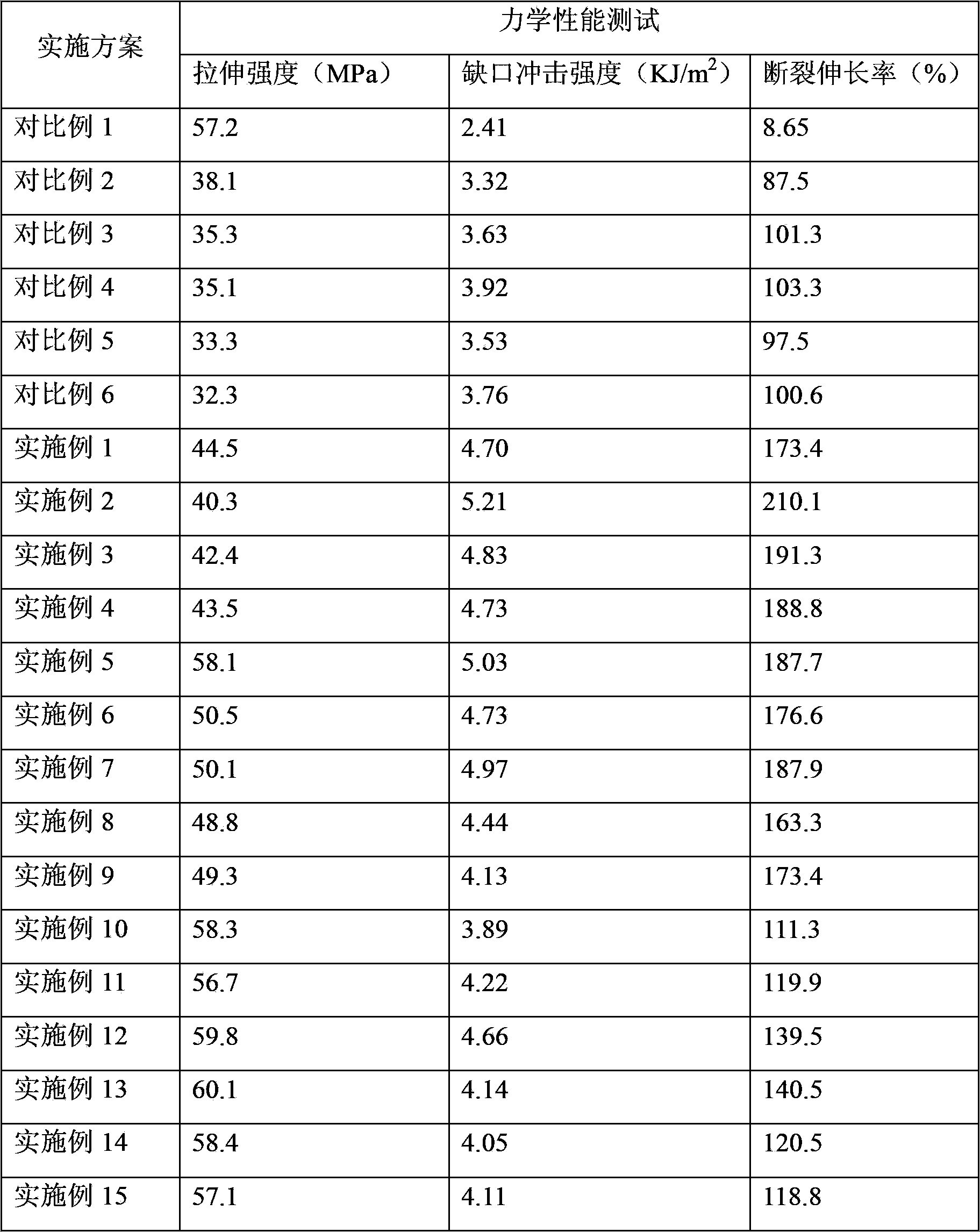

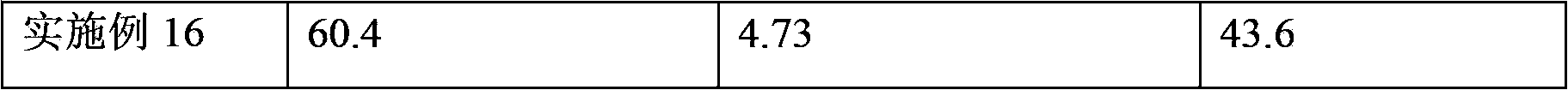

Examples

Embodiment 1

[0043] In this embodiment, the biodegradable high-toughness polylactic acid resin is composed of poly-L-lactic acid resin, PCL, antioxidant butyl hydroxyanisole, heat stabilizer triaryl phosphite, modifier maleic anhydride and calcium carbonate; In terms of weight fractions, the weight content of poly L-lactic acid is 75%, the weight content of PCL is 7.5%, the weight content of butyl hydroxyanisole is 5%, the weight content of triaryl phosphite is 5%, and the weight content of calcium carbonate is 5%. , The weight content of maleic anhydride is 2.5%.

[0044] The specific preparation method is as follows:

[0045] (1) Add 5g of calcium carbonate (5% by weight) and 7.5g of PCL (7.5% by weight) into the internal mixer according to the stated ratio and banbury at 150°C for 5 minutes to obtain calcium carbonate and PCL Form a "core-shell" structure masterbatch;

[0046] (2) According to the ratio, 75g of polylactic acid 101 resin (poly L-lactic acid) produced by Zhejiang Hisun ...

Embodiment 2

[0048] In this embodiment, the biodegradable high-toughness polylactic acid resin is made of poly-L-lactic acid resin, PCL, antistatic agent carbon black, 1250 mesh talcum powder and coupling agent isopropyl dioleic acid acyloxy (dioctyl phosphate acyloxy) Oxygen) titanate; according to the weight fraction, the weight content of poly L-lactic acid is 5%, the weight content of PCL is 80%, the weight content of carbon black is 5%, and the weight content of talcum powder is 10%;

[0049] Wherein the content of isopropyl dioleate acyloxy (dioctyl phosphate acyloxy) titanate in the talc powder is 1.5% of the mass of the talc powder.

[0050] Wherein the treatment steps of the inorganic material through the coupling agent are:

[0051] First add 20g of Nanjing Pinning Coupling Agent Co., Ltd. PN-102 brand titanate coupling agent (isopropyl dioleic acid acyloxy (dioctyl phosphate acyloxy) titanate) to 180g of acetone solution Make a solution in it, shake it well for later use, then ...

Embodiment 3

[0056] In this example, the biodegradable high-toughness polylactic acid resin is composed of poly-L-lactic acid resin, PBS, glycidyl methacrylate, montmorillonite and coupling agent (γ-aminopropylmethyltriethoxysilane) ; According to the weight fraction, the weight content of poly-L-lactic acid is 5%, the weight content of PBS is 35%, the weight content of PBSA is 40%, the weight content of glycidyl methacrylate is 5%, and the weight content of montmorillonite is 15%. ;

[0057] Wherein the content of γ-aminopropylmethyltriethoxysilane in the montmorillonite is 1% of the mass of the talcum powder.

[0058] Wherein the treatment steps of the inorganic material through the coupling agent are:

[0059] First add 20g of PN-902 silane coupling agent (γ-aminopropylmethyltriethoxysilane) from Nanjing Pinning Coupling Agent Co., Ltd. to 180g of aqueous solution to make a solution, shake well for later use, and then take 0.15 g was added to 10g of montmorillonite and stirred at a hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Notched impact strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com