Harmlessness method for treating arsenic in antimony oxide

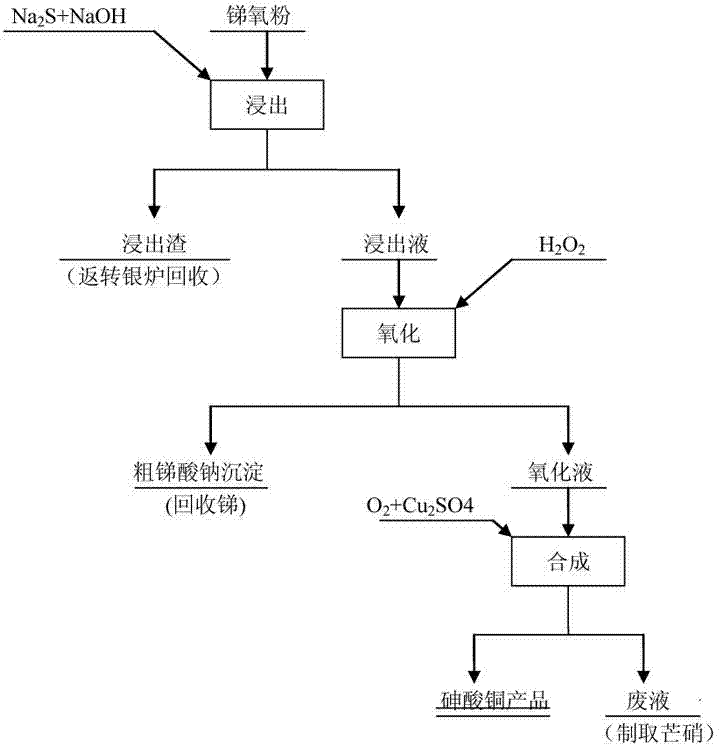

A technology of harmless treatment and antimony oxide powder, applied in chemical instruments and methods, inorganic chemistry, alkali metal compounds, etc., can solve the problems of easy environmental pollution by dearsenic liquid and antimony oxide powder environmental pollution, and achieve the adaptability of raw materials. Wide, safe production, short process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In this example, 200 g of antimony oxide powder contains antimony: 58.33, arsenic: 5.36, and lead: 10.41. When the mixture is leached, the liquid-solid ratio is 4:1, sodium sulfide 50g, sodium hydroxide 60g, temperature 95℃, stirring reaction for 3h, arsenic leaching rate is 99.50%, antimony 98.91%. The amount of hydrogen peroxide added to the leaching solution is 1.2 times the mass of arsenic and antimony in the solution. At room temperature, the stirring reaction time is 1.5h, and the antimony precipitation rate is 99.91%. Pour pure oxygen into the filtered oxidizing solution, the temperature is 90 °C, the amount of copper sulfate added is 3 times the mass of arsenic in the solution, and the reaction is stirred for 1 h. The copper arsenate precipitate is filtered, washed, and baked at 75 °C for 1.5 h, 35.7 g of copper arsenate was obtained, and the product composition (%) was copper: 32.1 and arsenic 28.3.

Embodiment 2

[0028] The antimony oxide powder in this embodiment is 200 g, containing 60.12 antimony, 5.87 arsenic, and 9.79 lead. When the mixture is leached, the liquid-solid ratio is 5:1, sodium sulfide 65g, sodium hydroxide 75g, temperature 90℃, stirring reaction for 3h, arsenic leaching rate is 99.85%, antimony 99.02%. The amount of hydrogen peroxide added to the leaching solution was 1.3 times the mass of arsenic and antimony in the solution. At room temperature, the reaction was stirred for 1.5 hours, and the antimony precipitation rate was 99.95%. Pour pure oxygen into the filtered oxidizing solution, the temperature is 93 °C, the amount of copper sulfate added is 2.8 times the mass of the solution containing arsenic, and the reaction is stirred for 1 hour. 36.4g copper arsenate, the product composition (%) is copper: 31.7, arsenic 29.0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com