Preparation method for metal-doped lithium/carbon manganese phosphate composite from manganese phosphate

A carbon composite material, lithium manganese phosphate technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of difficult to improve and solve the yield, difficult to ensure the stability of product batches, poor material conductivity, etc., to reduce Effects of natural cooling time, improved electrochemical performance, and improved batch performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

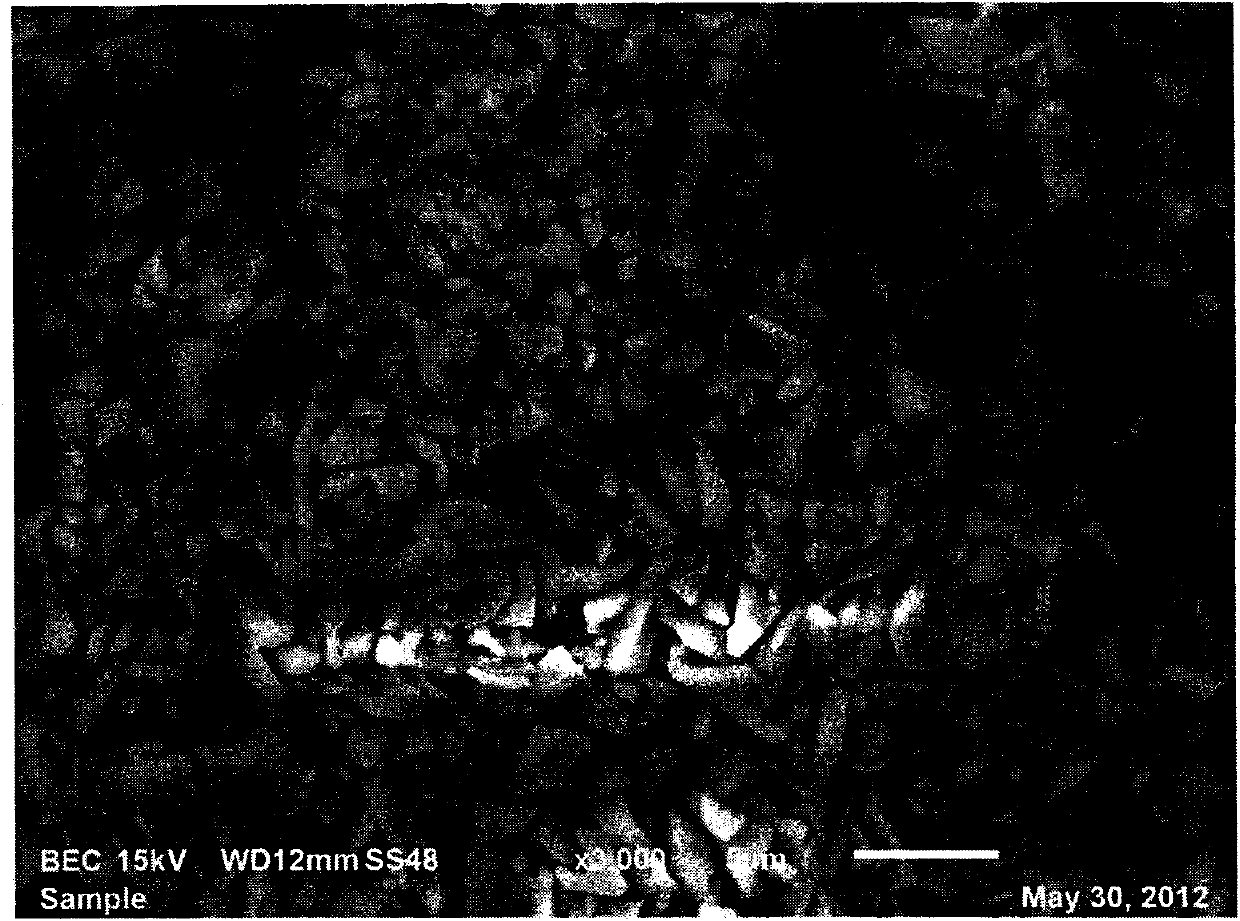

[0041] Embodiment 1, under room temperature, get manganese sulfate 82.82g, the solution that concentration is 1mol / L (99.5% of industrial high purity) and phosphoric acid 57.62g (AR) are made into the solution of 500ml, after stirring evenly, add oxidant hydrogen peroxide 50ml (excessive ), oxidize divalent manganese to trivalent manganese, the color of the solution becomes darker, continue to stir for 2 hours under rapid stirring at 500-100r / min, then heat to 50°C, and adjust the pH value with 1mol / L ammonium bicarbonate solution , The feeding rate is 500ml / h. Use a pH instrument to control the pH value to 5.5, then continue to stir and keep warm for 2 hours, then filter, beat and wash for 3 times, wait until the filtrate is added with BaCl2 without white precipitation, and finally adjust to 60°C in a vacuum oven and dry for 24 hours. The manganese phosphate precursor material is obtained by pulverization and classification, and its electron microscope SEM sees figure 1 .

...

example 2

[0043] Example 2, at room temperature, get manganese sulfate 82.82g, concentration is 1mol / L solution (industrial high purity 99.5%) and phosphoric acid 57.62g (AR) are respectively made into 500ml solution, mixes 200ml deionized water bottom liquid, adds oxidizing agent Hydrogen peroxide 50ml (excess). Manganese sulfate solution, phosphoric acid solution and 1mol / L ammonia solution were added dropwise in parallel to adjust the pH value, and the feeding rate was 50ml / h. Use a pH instrument to control the pH value from 4.5 to 5.5, then continue to stir and keep warm for 2 hours, then filter, beat and wash for 3 times, wait until the filtrate is added with BaCl2 without white precipitation, and finally adjust to 60°C in a vacuum oven and dry for 24 hours. Finally, the manganese phosphate precursor material is obtained by crushing and grading, and its electron microscope SEM sees Figure 5 .

[0044] Manganese phosphate 100g (self-made), lithium carbonate 24.76g (battery grade ...

example 3

[0045] Example 3, at room temperature, get manganese acetate 123.78g, concentration is 1mol / L solution (99.5% of industrial high purity) and phosphoric acid 57.62g (AR) and is made into 500ml solution, after stirring evenly, add oxidant hydrogen peroxide 50ml (excessive) , oxidize divalent manganese to trivalent manganese, the color of the solution becomes darker, continue to stir for 2 hours, then heat to 50°C, continue to stir and react for 2 hours, then add polyethylene glycol (PEG) 1000, heat to 80 ℃ to continue to react for 2 hours, and finally evaporate to jelly, put it in a vacuum oven at 60 ℃ and dry for 24 hours, and finally pulverize and classify to obtain the manganese phosphate precursor material. Its electron microscope SEM sees Figure 7

[0046]Manganese phosphate 100g (self-made) prepared above, lithium carbonate 24.76g (battery grade 99.5%), magnesium hydroxide 0.757g (nano-grade), glucose 11.67g (food grade 99.5%), use 150ml absolute ethanol as dispersant ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com