Copolymer modified acrylic acid anticorrosive coating and manufacture method thereof

A technology for anti-corrosion coatings and copolymer modification, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of poor impact resistance and flexibility of coatings, affect the anti-corrosion effect of coatings, and poor compactness, and achieve good adhesion, Good impact resistance and excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The copolymer-modified acrylic anticorrosion paint that is used for anticorrosion of steel structures of the present invention is made of 1 weight part thermoplastic acrylic resin, 0.38 weight part chlorinated ethylene vinyl acetate copolymer, 2.3 weight parts xylene, 1.1 weight part n-butanol, 0.8 parts by weight of butyl acetate, 0.07 parts by weight of cellulose acetate butyrate, 0.28 parts by weight of petroleum resin, 0.33 parts by weight of rutile titanium dioxide, 0.15 parts by weight of talc, 0.1 parts by weight of The dispersant of mica powder, 0.02 parts by weight 0.01 parts by weight of adhesion improver, 0.007 parts by weight of anti-scratch agent, 0.01 parts by weight of non-organic silicon defoamer 0.008 parts by weight of leveling agent 0.008 parts by weight of anti-settling agent and 0.007 parts by weight of ultraviolet absorber. It can be used after stirring well.

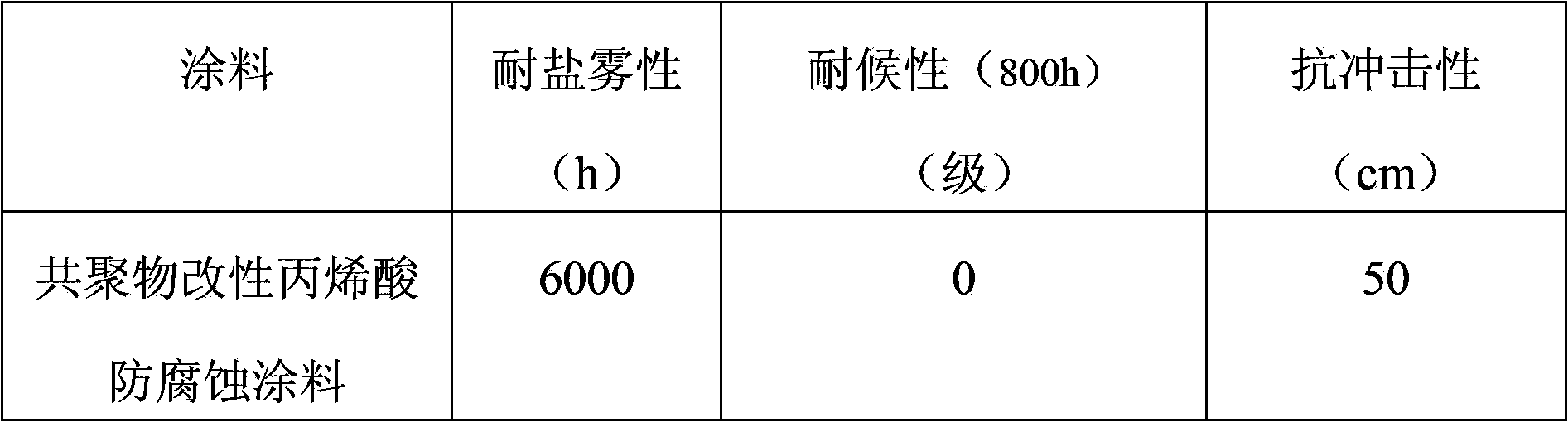

[0020] The main results of the experiment are shown in the table below.

[0021] ...

Embodiment 2

[0023] The copolymer modified acrylic acid anticorrosion coating that is used for anticorrosion of steel structures of the present invention is made of 1 weight part thermoplastic acrylic resin, 0.42 weight part chlorinated ethylene vinyl acetate copolymer, 2.3 weight parts xylene, 1.1 weight part n-butanol, 0.8 parts by weight of butyl acetate, 0.1 parts by weight of cellulose acetate butyrate, 0.28 parts by weight of petroleum resin, 0.33 parts by weight of rutile titanium dioxide, 0.2 parts by weight of talc, 0.1 parts by weight of The dispersant of mica powder, 0.02 parts by weight 0.01 parts by weight of adhesion improver, 0.007 parts by weight of anti-scratch agent, 0.01 parts by weight of non-organic silicon defoamer 0.008 parts by weight of leveling agent 0.008 parts by weight of anti-settling agent and 0.007 parts by weight of ultraviolet absorber. It can be used after stirring well.

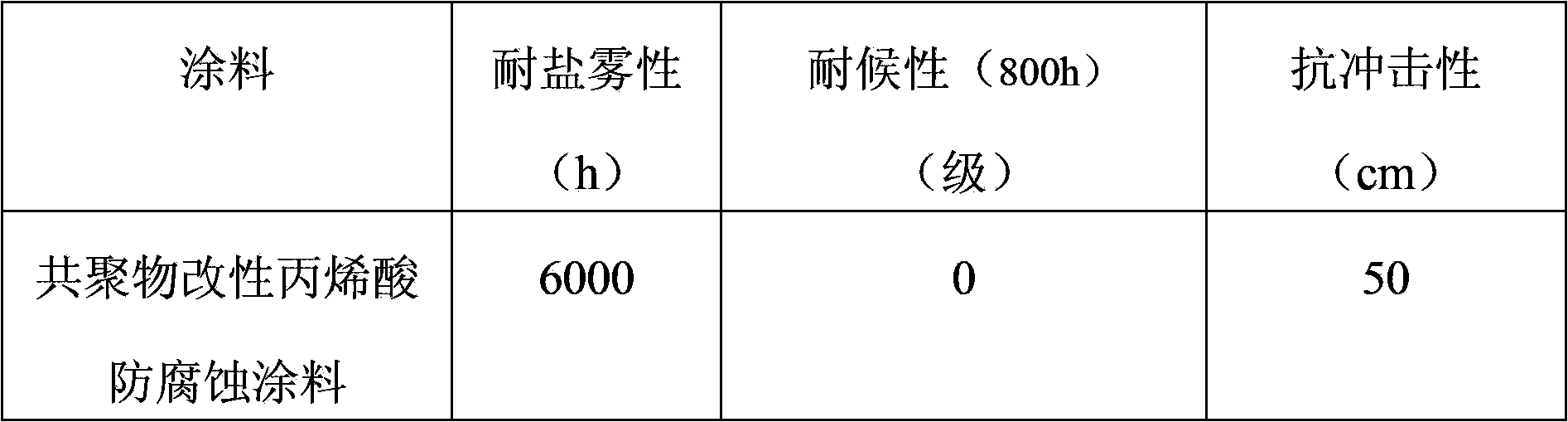

[0024] The main results of the experiment are shown in the table below.

[002...

Embodiment 3

[0027] The copolymer modified acrylic acid anticorrosion coating that is used for anticorrosion of steel structures of the present invention is made of 1 weight part thermoplastic acrylic resin, 0.42 weight part chlorinated ethylene vinyl acetate copolymer, 2.3 weight parts xylene, 1.1 weight part n-butanol, 0.8 parts by weight of butyl acetate, 0.1 parts by weight of cellulose acetate butyrate, 0.28 parts by weight of petroleum resin, 0.33 parts by weight of rutile titanium dioxide, 0.2 parts by weight of talc, 0.1 parts by weight of The dispersant of mica powder, 0.02 parts by weight 0.01 parts by weight of adhesion improver, 0.007 parts by weight of anti-scratch agent, 0.01 parts by weight of non-organic silicon defoamer 0.008 parts by weight of leveling agent 0.008 parts by weight of anti-settling agent and 0.007 parts by weight of ultraviolet absorber. It can be used after stirring well.

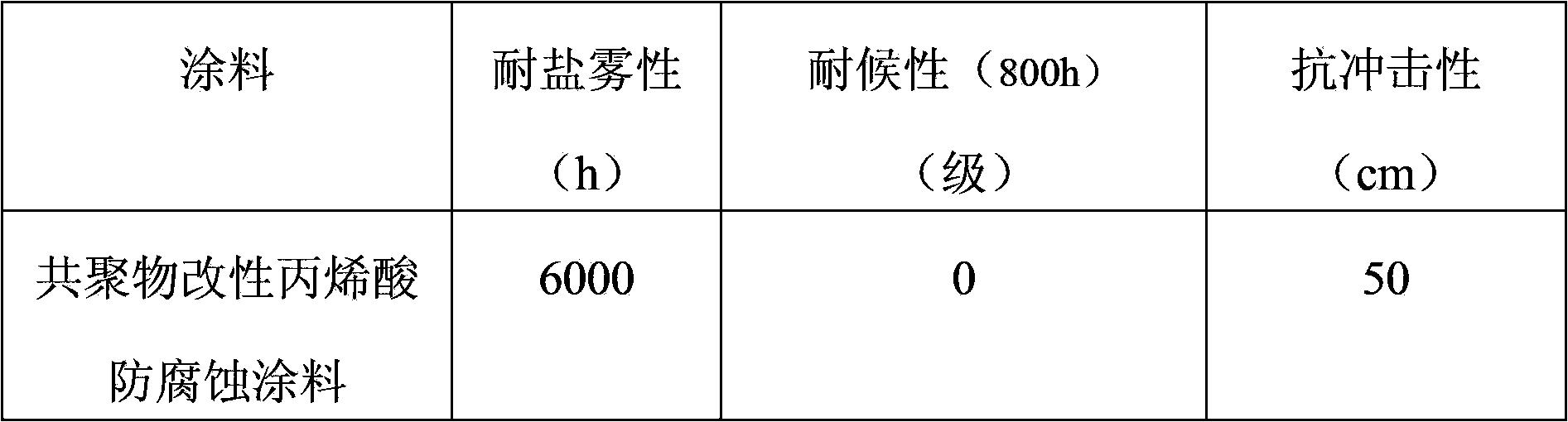

[0028] The main results of the experiment are shown in the table below.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com