Flame-retardant plastic-steel composite cable protection pipe and preparation method thereof

A composite cable and protection tube technology, which is applied in the installation of cables and ground cables, etc., can solve the problems of poor flame retardancy, failure to meet market requirements, and poor creep resistance of composite cable protection tubes, and is easy to achieve The effect of passing through, avoiding stuck cables, and strong load and pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

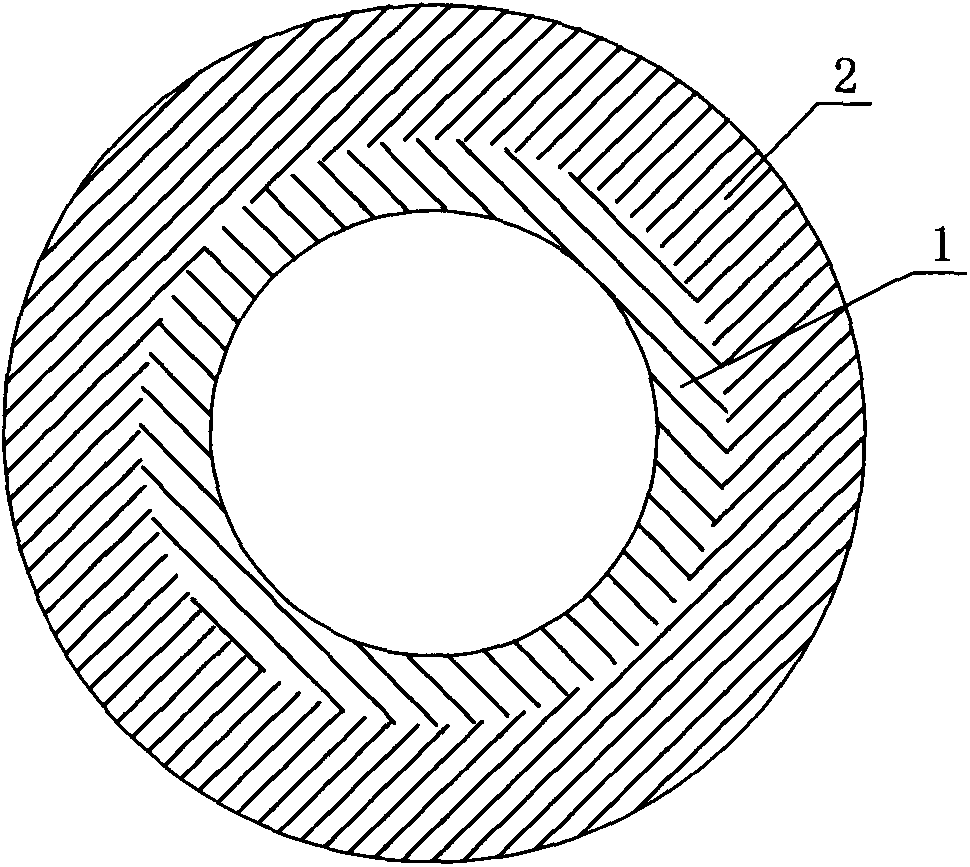

[0025] like figure 1 As shown, the flame-retardant plastic-steel composite cable protection tube is made of a flame-retardant inner tube 1 and a flame-retardant outer tube. Tube 2.

[0026] The flame-retardant inner pipe 1 is made of the following raw materials in parts by weight: 23 kg of polypropylene, 2 kg of polyethylene, 22 kg of defoamer, 55 kg of high-pressure polyethylene filler masterbatch, 6 kg of flame retardant red phosphorus, smoke suppressant Agent antimony trioxide 3.75 kg, molybdenum trioxide 1.25 kg, magnesium hydroxide 25 kg.

[0027] The flame retardant outer tube is made of the following raw materials in parts by weight: 86 kg of unsaturated polyester resin, 10 kg of flame retardant dimethyl methyl phosphate, 9.5 kg of talcum powder, and 0.5 kg of silane coupling agent.

[0028] The preparation method of the flame-retardant plastic-steel composite cable protection tube comprises the following steps:

[0029] (1) Preparation of flame retardant inner tube ...

Embodiment 2

[0034] The flame-retardant plastic-steel composite cable protection tube is made of a flame-retardant inner tube 1 and a flame-retardant outer tube.

[0035] The flame-retardant inner pipe 1 is made of the following raw materials in parts by weight: 22 kg of polypropylene, 3 kg of polyethylene, 10 kg of defoamer, 30 kg of high-pressure polyethylene filler masterbatch, 2 kg of flame retardant red phosphorus, smoke suppressant Agent antimony trioxide 1.5 kg, molybdenum trioxide 0.5 kg, magnesium hydroxide 20 kg.

[0036] The flame retardant outer tube is made of the following raw materials in parts by weight: 80 kg of unsaturated polyester resin, 6 kg of flame retardant dimethyl methyl phosphate, 16.5 kg of talcum powder, and 0.5 kg of silane coupling agent.

[0037] The outer surface of the flame-retardant inner tube 1 produced in step (1) is grooved, and the rest of the preparation method is the same as in Example 1. Grooving is performed on the outer surface of the flame-ret...

Embodiment 3

[0039] The flame-retardant plastic-steel composite cable protection pipe is made of a flame-retardant inner pipe 1 and a flame-retardant outer pipe.

[0040] The flame-retardant inner pipe 1 is made of the following raw materials in parts by weight: 24 kg of polypropylene, 1 kg of polyethylene, 35 kg of defoamer, 80 kg of high-pressure polyethylene filler masterbatch, 10 kg of flame retardant red phosphorus, smoke suppressant Agent antimony trioxide 6 kg, molybdenum trioxide 2 kg, magnesium hydroxide 30 kg.

[0041] The flame retardant outer tube is made of the following raw materials in parts by weight: 92 kg of unsaturated polyester resin, 15 kg of flame retardant dimethyl methyl phosphate, 2.5 kg of talcum powder, and 0.5 kg of silane coupling agent.

[0042] The outer surface of the flame-retardant inner tube 1 produced in step (1) is roughened, and the rest of the preparation method is the same as in Example 1. The roughening treatment on the outer surface of the flame-r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com