Novel high-thermal-conductive packaging material for solar module

A technology for solar modules and packaging materials, used in semiconductor devices, electrical components, adhesive types, etc., can solve the problem of low thermal conductivity, and achieve the effects of excellent bonding performance, high cross-linking density, and lower surface temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

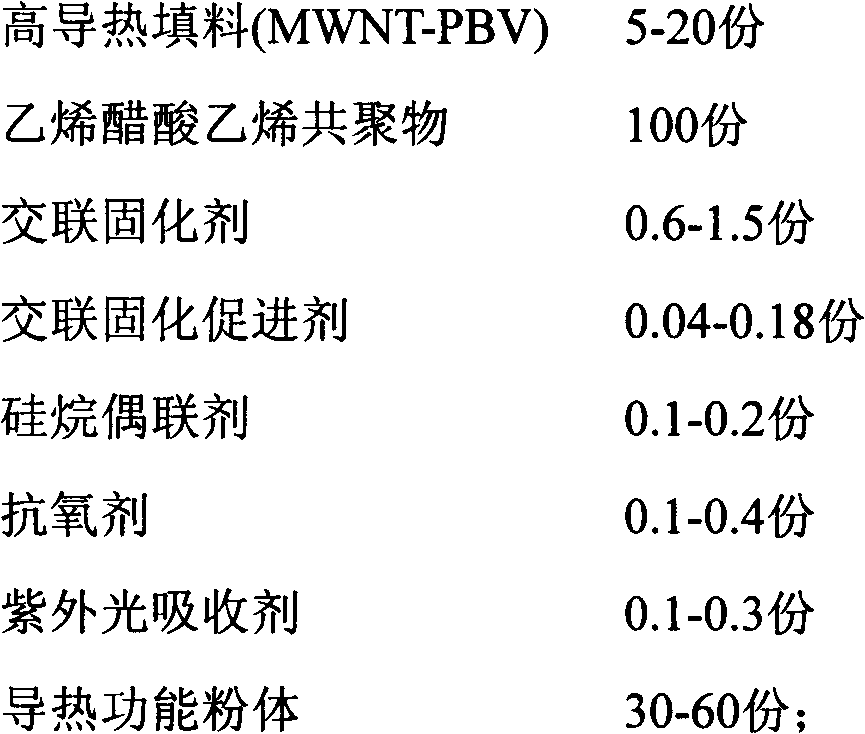

Method used

Image

Examples

Embodiment 1

[0013] A heat-conducting solar cell encapsulation material, consisting of 100 parts by mass of vinyl acetate (EVA), 0.6 parts by mass of tackifier r-glycidyl ether oxypropyltrimethoxysilane, 0.8 parts by mass of crosslinking curing agent dicumyl peroxide , 0.2 parts by mass of benzoyl peroxide, 0.1 parts by mass of crosslinking curing accelerator 1,2-divinylbenzene, 0.3 parts by mass of antioxidant two (2,4-dicumylphenyl) pentaerythritol diethylene Phosphate ester, 0.3 parts by mass of ultraviolet absorber fumed silica, 0.2 parts by mass of silane coupling agent KH-550, and 5 parts by mass of MWNT-PVBV, mixed uniformly and put into an extruder for mixing and plasticizing, extruding The machine temperature was controlled at 85°C. Extrude, cut into pellets, and press molding to obtain thermally conductive solar cell encapsulation EVA adhesive film F-01.

Embodiment 2

[0015] A thermally conductive solar cell encapsulation material, consisting of 100 parts by mass of vinyl acetate (EVA), 0.5 parts by mass of tackifier r-glycidyl ether oxypropyl trimethoxysilane, 0.9 parts by mass of crosslinking curing agent dicumyl peroxide , 0.2 parts by mass of benzoyl peroxide, 0.1 parts by mass of crosslinking curing accelerator triallyl isocyanurate, 0.15 parts by mass of antioxidant two (2,4-dicumylphenyl) pentaerythritol di Phosphite, 0.15 parts by mass of antioxidant distearyl pentaerythritol diphosphite, 0.3 parts by mass of UV absorber benzophenone, 0.2 parts by mass of silane coupling agent KH-570, 10 parts by mass of MWNT- PBV, after mixing evenly, put it into the extruder for mixing and plasticizing, and the temperature of the extruder is controlled at 88°C. Extrude, cut into pellets, and press molding to obtain thermally conductive solar cell encapsulation EVA film F-02.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com