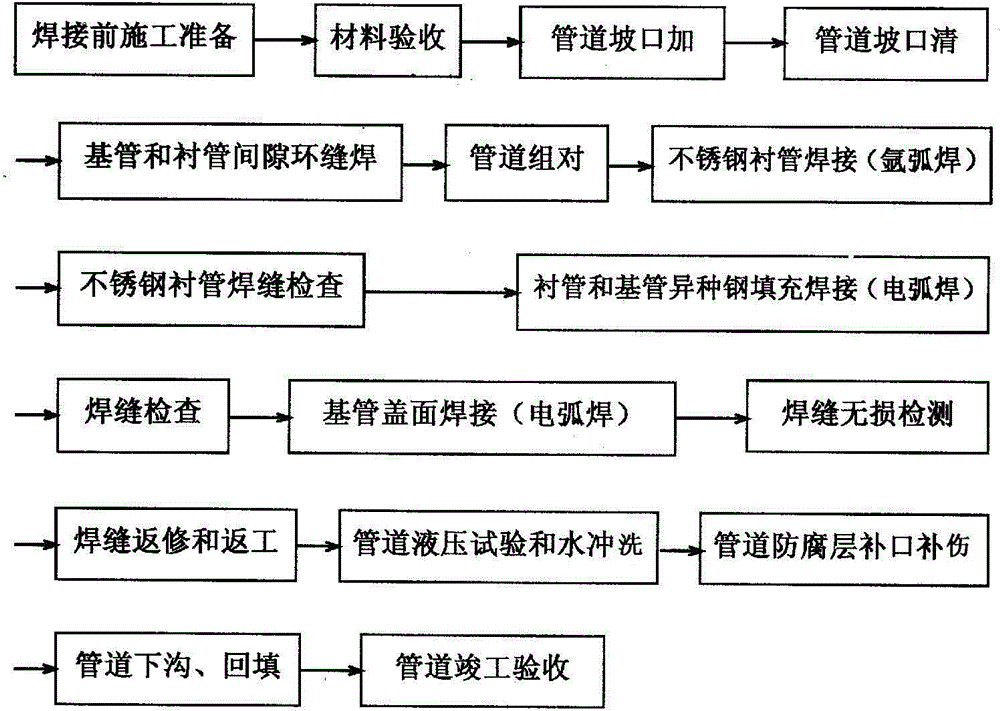

Bimetal clad steel pipe welding method

A composite steel pipe, bimetal technology, applied in welding equipment, metal processing equipment, arc welding equipment and other directions, can solve the problems of short service life, easy to be damaged, high maintenance cost, reduce safety hazards, not easy to pipeline leakage, welding Reliable quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] 1. Equipment and material acceptance: All pipes, fittings, valves, welding consumables, etc. must have certificates of conformity and material quality certificates before leaving the factory. The appearance inspection of the pipeline shall not have defects such as cracks, folds, shrinkage cavities, slag inclusions, corrosion that does not exceed the negative tolerance of wall thickness, pitting, pollution of different materials, and mechanical damage.

[0026] 2. Pipeline anticorrosion treatment: Sandblasting and derusting methods are used for pipeline surface treatment. Anticorrosion materials should be evenly prepared, matured, and painted in time according to the ratio specified by the material. After each coating is applied, dry film testing and Coating inspection.

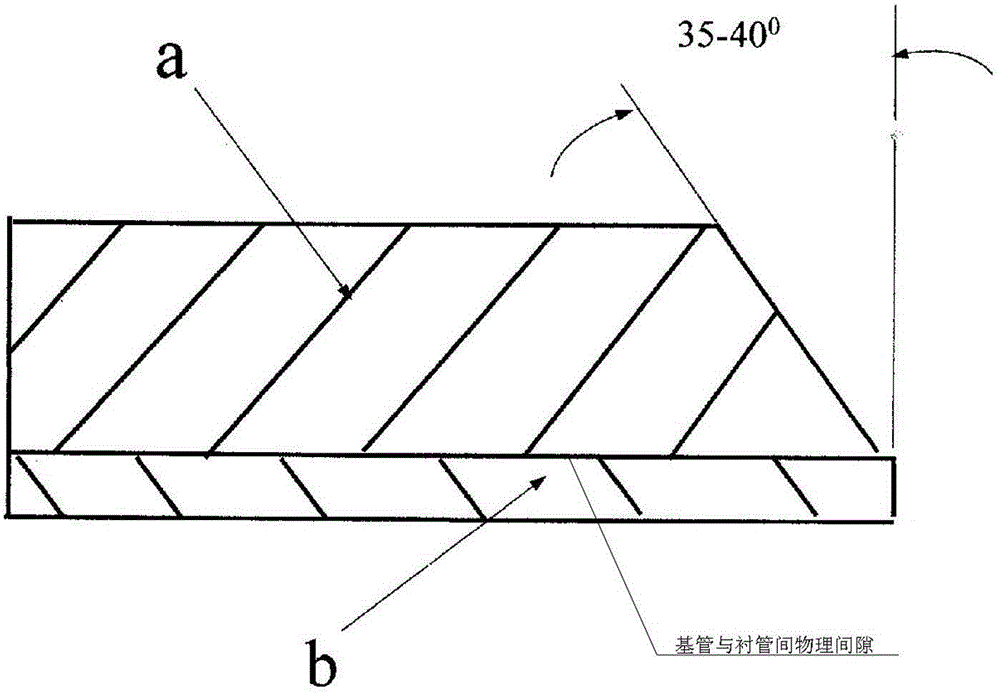

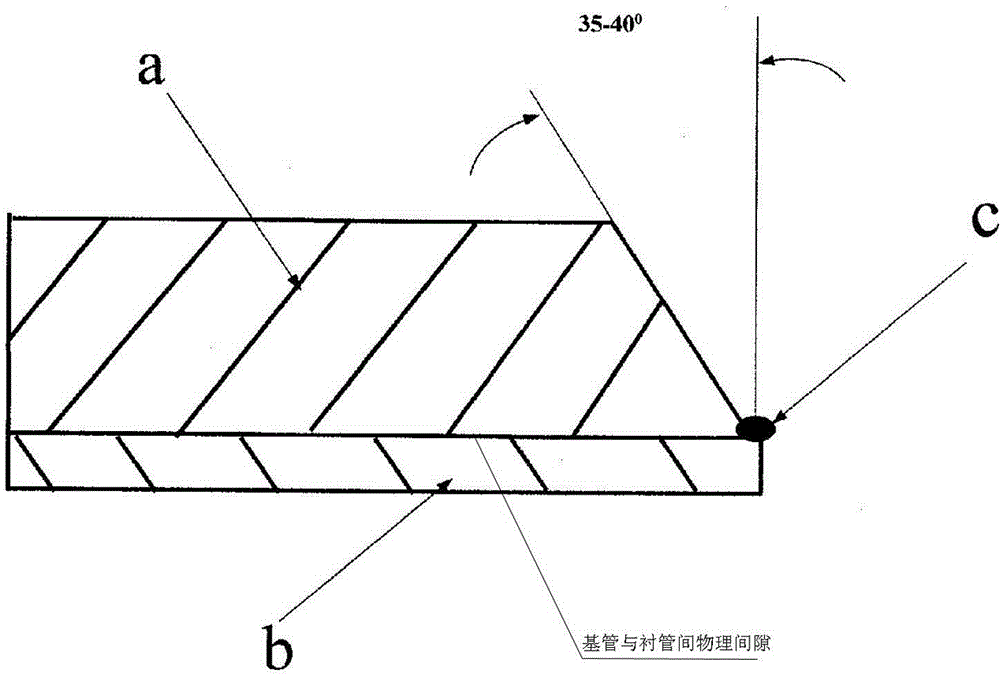

[0027] 3. Pipe groove processing: The groove form of the pipe welded joint should adopt V-shaped groove. Plasma cutting or cold cutting can be used to cut bimetallic composite steel pipes. Composite st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com