Solder paste for soft brazing of aluminum and aluminum alloy and preparation method thereof

An aluminum alloy and soldering technology, applied in the field of solder paste for aluminum and aluminum alloy soldering and its preparation, can solve the problems of high soldering temperature, difficulty in soldering, and no discovery, etc. Good corrosion resistance, improved corrosion resistance, and the effect of improving overall activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

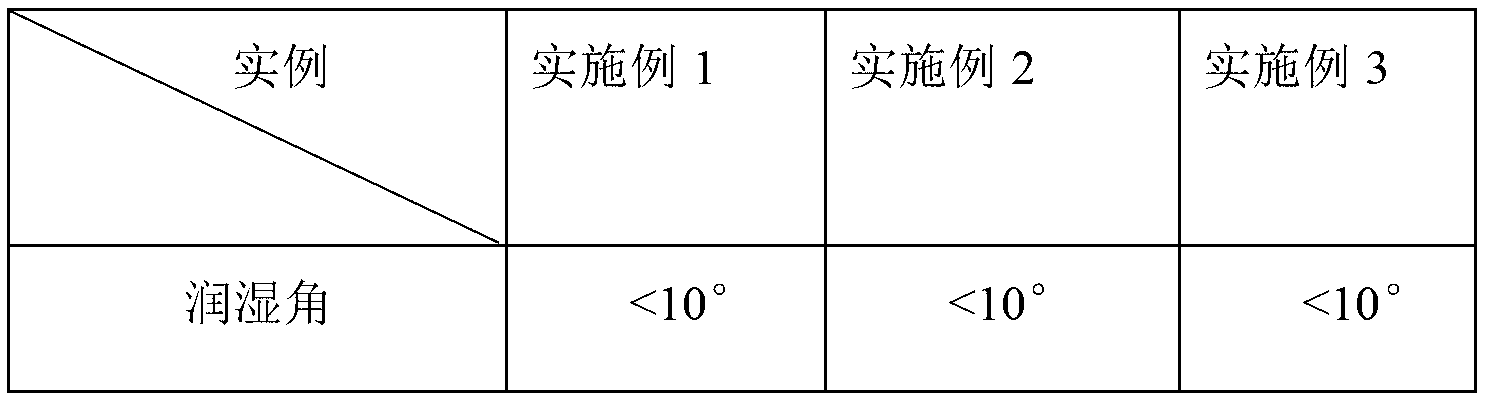

Examples

Embodiment 1

[0036] A solder paste for aluminum and aluminum alloy soldering, which consists of solder alloy powder and flux, wherein:

[0037] The raw material composition and weight of the solder alloy powder are: tin 15Kg, silver 1Kg, lead 84Kg;

[0038] The raw material components and weights of the flux are: 1.8Kg of zinc fluoride, 13.2Kg of tin fluoride, 70Kg of hydrofluoric acid salt of polyhydroxylamine, and 15Kg of ethylene glycol.

[0039] The above-mentioned preparation steps for the solder paste for aluminum and aluminum alloy soldering are:

[0040] (1) Preparation of solder alloy powder: Weigh tin, lead, and silver in proportion, melt them at 320-380°C to form a uniform solder alloy, and spray powder with conventional methods to obtain a solder alloy powder of less than 300 mesh.

[0041] (2) Take 80% by weight of solder alloy powder (80kg) and 20% of flux (20kg) and mix them with a mixer to make a solder paste.

[0042] The preparation method of flux in the present embodim...

Embodiment 2

[0050] A solder paste for aluminum and aluminum alloy soldering is composed of solder alloy powder and flux.

[0051] The raw material composition and weight of solder alloy powder are: tin 30Kg, silver 3Kg, lead 67Kg;

[0052] The raw material components and weights of the flux are: 0.6Kg of zinc fluoride, 3.9Kg of tin fluoride, 0.5Kg of copper fluoride, 85Kg of hydrofluoric acid salt of polyhydroxylamine, and 10Kg of ethylene glycol.

[0053]The above-mentioned preparation steps for the solder paste for aluminum and aluminum alloy soldering are:

[0054] (1) Preparation of solder alloy powder: Weigh tin, lead, and silver in proportion, melt them into a uniform solder alloy at 320-380°C, spray powder with conventional methods, and prepare solder alloy powder of less than 300 meshes;

[0055] ⑵Mix 85% solder alloy powder (85kg) with 15% flux (15kg) by weight, and stir evenly with a mixer to make a solder paste.

[0056] The preparation method of the flux of the present embod...

Embodiment 3

[0064] A kind of solder paste for aluminum and aluminum alloy soldering, same as embodiment 1 and 2, same solder alloy powder and flux two parts are made up of, wherein:

[0065] The raw material composition and weight of the solder alloy powder are: tin 16Kg, silver 2Kg, lead 82Kg;

[0066] The raw material components and weights of the flux are: 1.2Kg of zinc fluoride, 7.2Kg of tin fluoride, 1.6Kg of bismuth fluoride, 70Kg of hydrofluoric acid salt of polyhydroxylamine, and 20Kg of ethylene glycol.

[0067] (1) The preparation steps of the above-mentioned solder paste for aluminum and aluminum alloy soldering are:

[0068] Preparation of solder alloy powder: weighing tin, lead, and silver in proportion, smelting at 320-380°C to form a uniform solder alloy, spraying powder with conventional methods, and preparing solder alloy powder of less than 300 meshes;

[0069] ⑵Mix 90% solder alloy powder (90kg) and 10% flux (10kg) by weight, and stir them evenly with a mixer to make a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com