A kind of environment-friendly titanium alloy anodic oxidation pretreatment method

An anodic oxidation and titanium alloy technology, applied in the direction of electrolytic coating, surface reaction electrolytic coating, coating, etc., can solve the problems of strong skin irritation, environmental pollution, corrosion, etc., and achieve low cost, convenient operation, and solution composition simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1. Prepare alkaline degreasing liquid

[0020] Add 20g of sodium silicate, 20g of sodium carbonate, and 50g of sodium hydroxide to 1L of deionized water, stir and dissolve uniformly.

[0021] 2. Prepare anodizing pretreatment solution

[0022] Add 5g of chromotropic acid and 5g of oxalic acid to 1L of deionized water, stir and dissolve evenly.

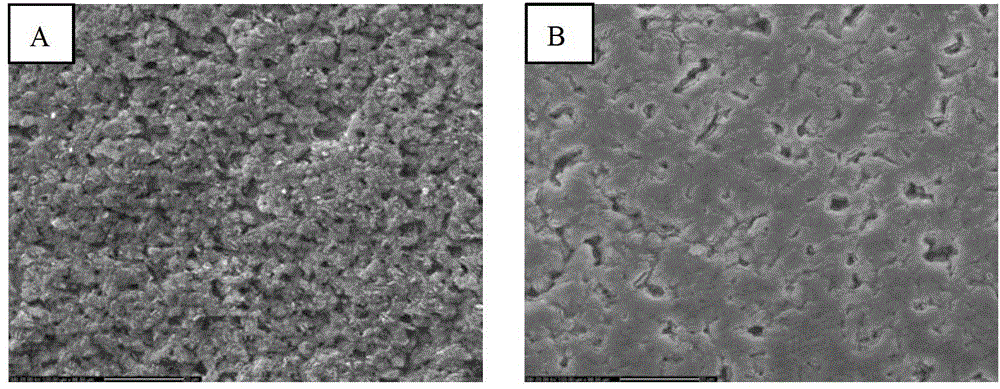

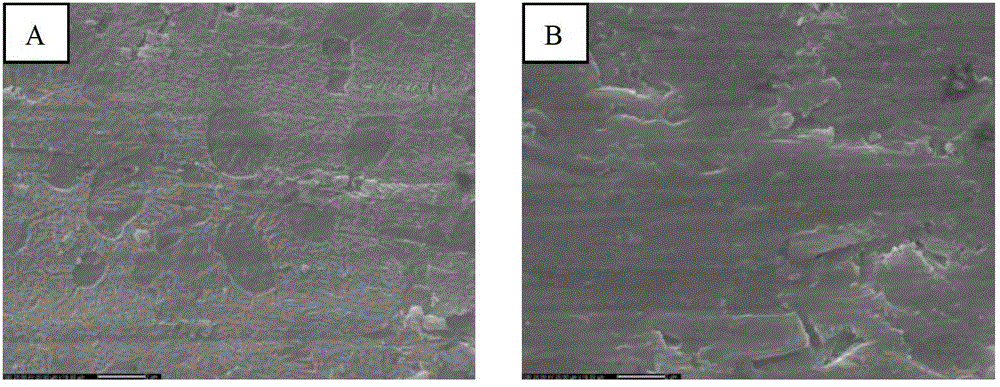

[0023] 3. Anodizing pretreatment

[0024] 1) Place the titanium alloy (TB6 titanium alloy in this example) in an acetone solution for ultrasonic cleaning for 5-10 minutes, and rinse with distilled water for use;

[0025] 2) Heat the prepared degreasing liquid in a water bath to 60°C, and put the titanium alloy treated in step 1) into the prepared degreasing liquid for alkaline washing and degreasing for 20 minutes, and then heat by flowing Washing in water, running cold water;

[0026] 3) Heat the prepared pretreatment solution in a water bath to 80°C, and put the titanium alloy treated in step 2) into the prepared anodizing pretreatmen...

Embodiment 2

[0031] 1. Prepare alkaline degreasing liquid

[0032] Add 20g of sodium silicate, 20g of sodium carbonate, and 50g of sodium hydroxide to 1L of deionized water, stir and dissolve uniformly.

[0033] 2. Prepare anodizing pretreatment solution

[0034] Add 1g of chromotropic acid and 10g of oxalic acid to 1L of deionized water, stir and dissolve evenly.

[0035] 3. Anodizing pretreatment

[0036] 1) Put the titanium alloy in an acetone solution for ultrasonic cleaning for 5-10 minutes, and then rinse it with distilled water for later use;

[0037] 2) Heat the prepared degreasing liquid in a water bath to 60°C, and put the titanium alloy treated in step 1) into the prepared degreasing liquid for alkaline washing and degreasing for 20 minutes, and then heat by flowing Washing in water, running cold water;

[0038] 3) Heat the prepared pretreatment solution in a water bath to 50°C, and put the titanium alloy treated in step 2) into the prepared anodizing pretreatment solution for 30 minute...

Embodiment 3

[0043] 1. Prepare alkaline degreasing liquid

[0044] Add 20g of sodium silicate, 20g of sodium carbonate, and 50g of sodium hydroxide to 1L of deionized water, stir and dissolve uniformly.

[0045] 2. Prepare anodizing pretreatment solution

[0046] Add 1g of chromotropic acid and 2g of oxalic acid to 0.5L of deionized water, stir and dissolve evenly.

[0047] 3. Anodizing pretreatment

[0048] 1) Put the titanium alloy in an acetone solution for ultrasonic cleaning for 5-10 minutes, and then rinse it with distilled water for later use;

[0049] 2) Heat the prepared degreasing liquid in a water bath to 60°C, and put the titanium alloy treated in step 1) into the prepared degreasing liquid for alkaline washing and degreasing for 20 minutes, and then heat by flowing Washing in water, running cold water;

[0050] 3) Heat the prepared pretreatment solution in a water bath to 70°C, and put the titanium alloy treated in step 2) into the prepared anodizing pretreatment solution for 20 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com