Diffusion bonding method of hard alloy and metal

A cemented carbide and diffusion joining technology, applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve the problems of low connection strength and complex process, improve the bearing capacity, increase the connection area, and facilitate mass production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

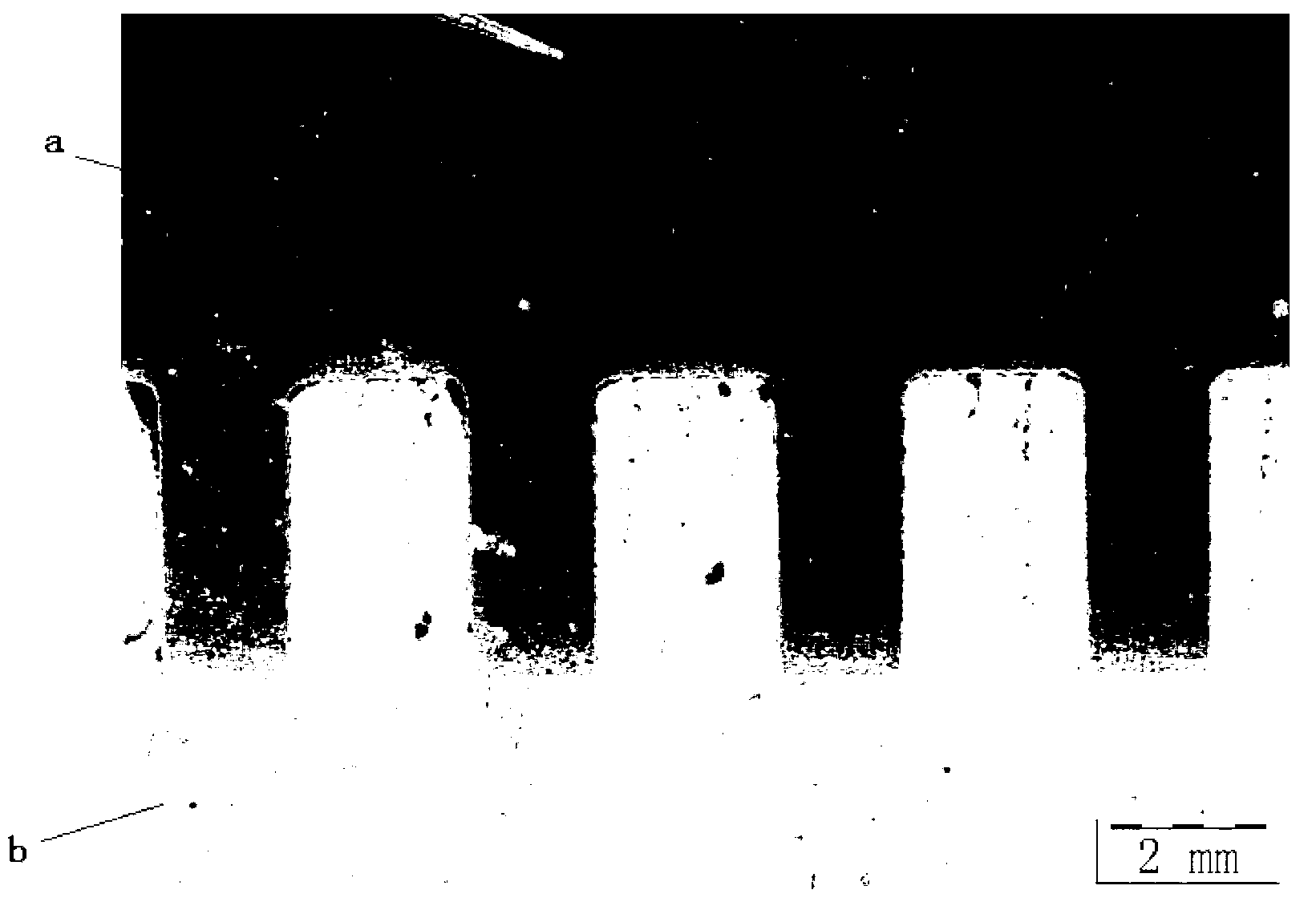

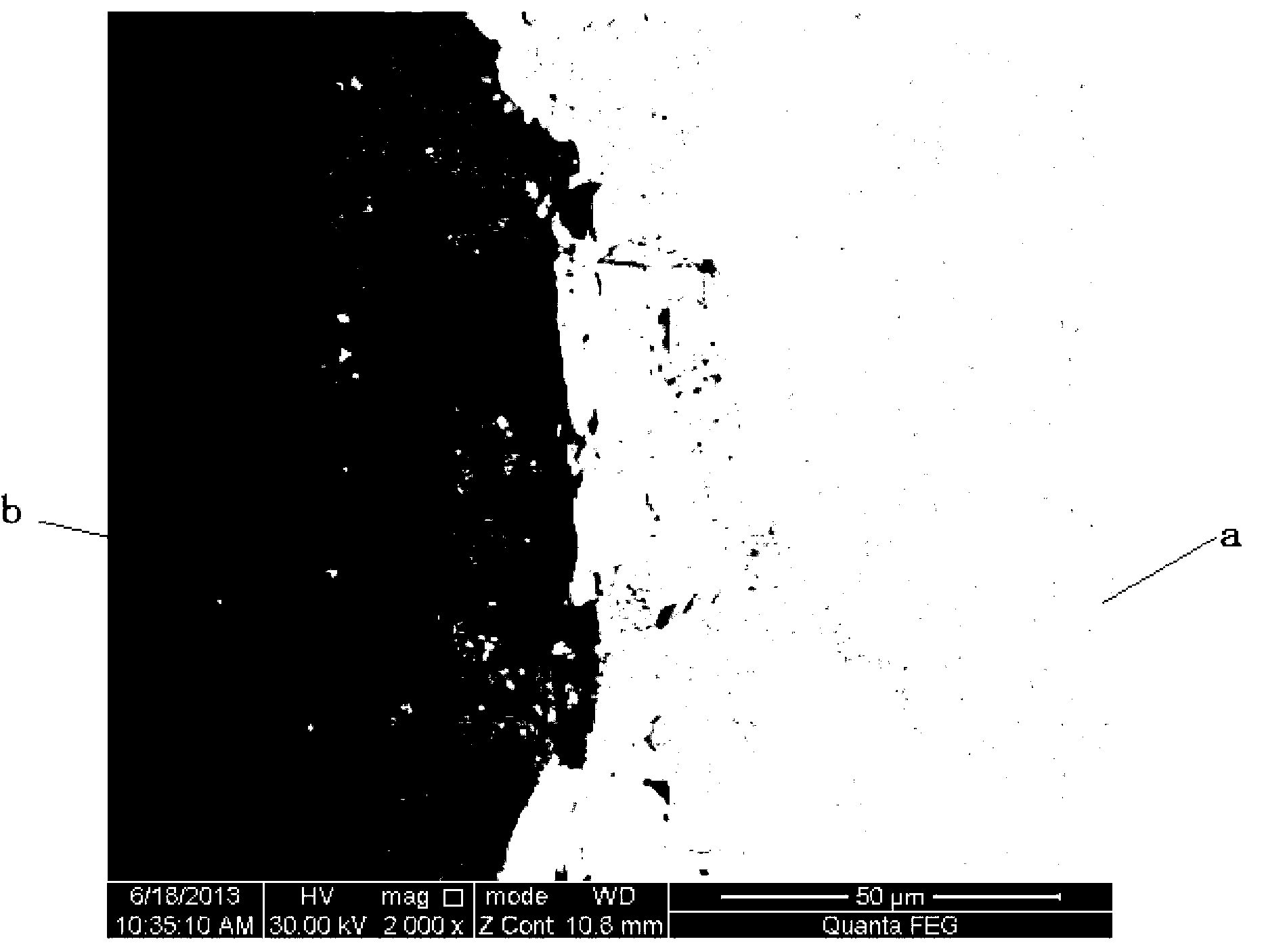

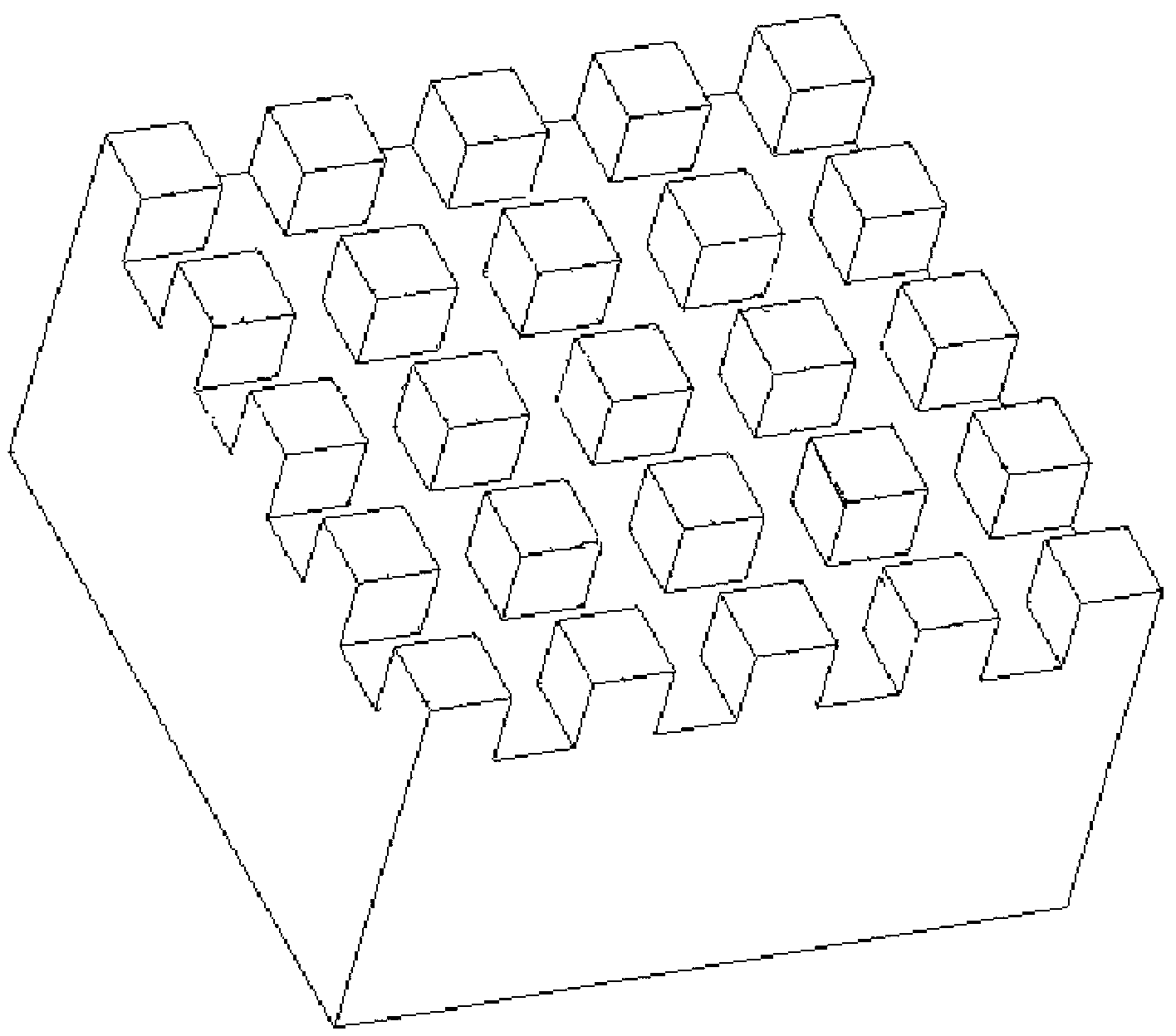

[0012] Specific embodiment one: a kind of diffusion bonding method of cemented carbide and metal in this embodiment is carried out through the following steps: 1. Texturing boss: by computer programming, cut the cemented carbide to be welded with a wire cutting machine Surface, so that the surface of the cemented carbide to be welded generates matrix bosses;

[0013] 2. Cleaning before welding: Use 80#, 200#, 400# and 800# sandpaper to grind the metal surface to be welded step by step, then put it in acetone for ultrasonic cleaning for 3-10min, and then dry it naturally to get the cleaned metal ; Put the hard alloy surface with the matrix boss into acetone and ultrasonically clean it for 5 minutes and then dry it to obtain the cleaned hard alloy;

[0014] 3. Diffusion connection: butt the surface to be welded of the cleaned hard alloy with the surface to be welded of the cleaned metal, then put it into a diffusion welding furnace, fix it with a pressure head, and then carry ou...

specific Embodiment approach 2

[0016] Embodiment 2: This embodiment differs from Embodiment 1 in that: the height of the boss described in Step 1 is 1-2 mm, and the cross-section is 1×1 mm. Others are the same as the first embodiment.

specific Embodiment approach 3

[0017] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the cemented carbide in step 1 is YG6, YG8 or YG15. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com