Cu-doped lithium zinc titanate negative electrode material and preparation method thereof

A technology of lithium zinc titanate and negative electrode material, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of crystal structure distortion, poor material cycle performance, etc., to reduce the preparation cost, high production efficiency, and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

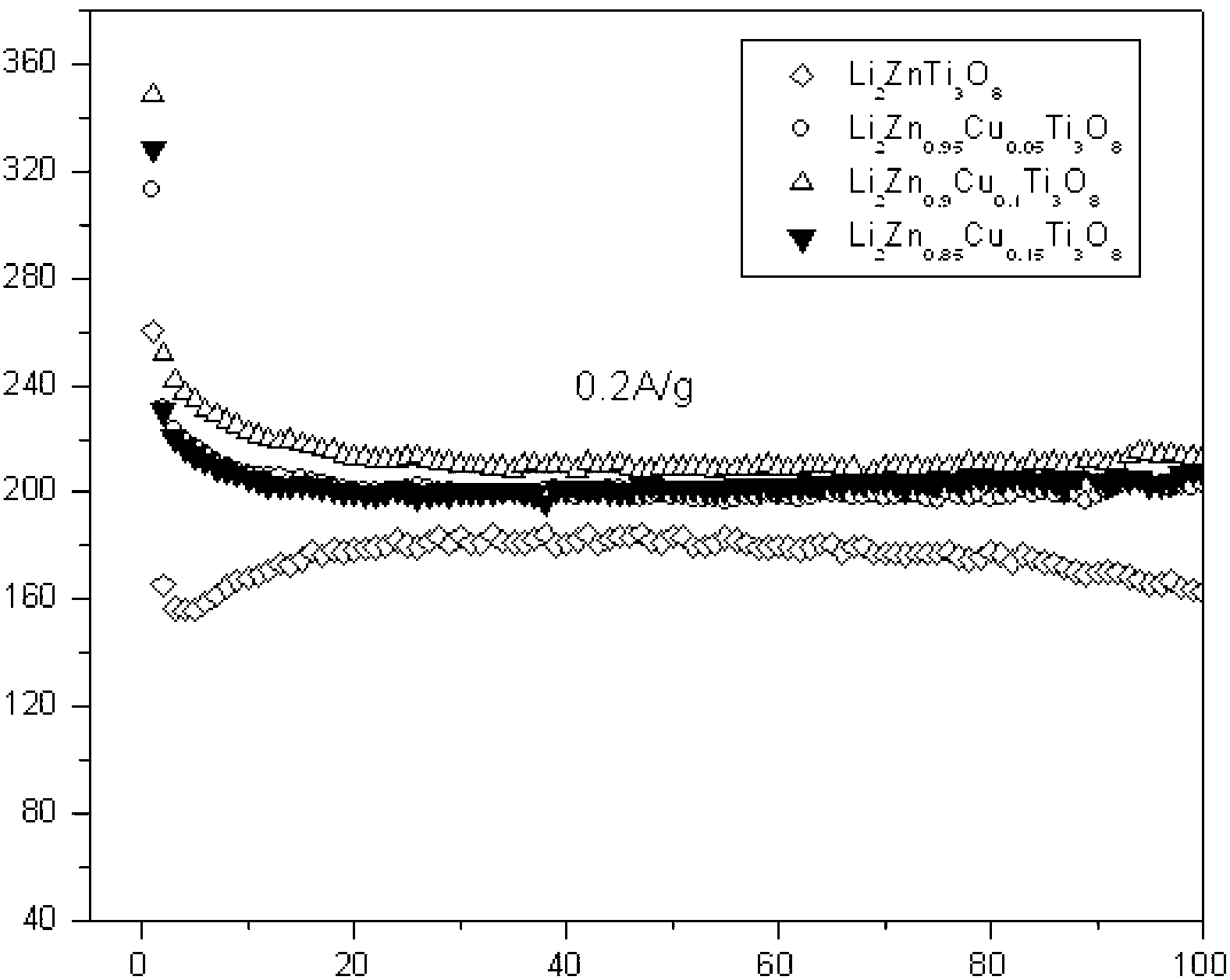

Embodiment 1

[0024] x=0.05, the molecular formula is: Li 2 Zn 0.95 Cu 0.05 Ti 3 o 8 , the preparation process is as follows:

[0025] Weigh out 1 gram of H 2 Ti 3 o 7 , 0.287 g Li 2 CO 3 Put it into a beaker, add 20ml of absolute ethanol, mix well, weigh 0.809g of Zn(CH 3 COO) 2 2H 2 O and 0.039 g Cu(CH 3 COO) 2 ·H 2 O was added to the above solution, and the above solution was evaporated to dryness at 70°C with stirring, ground, placed in a muffle furnace, heated to 750°C at 3°C / min, and kept for 5 hours to obtain a Cu-doped lithium zinc titanate product .

[0026] Weigh 0.7 g of the product, mix it with acetylene black and PVDF in a mass ratio of 70:20:10, stir evenly, coat it on a copper foil, place it in a vacuum oven, and dry it under vacuum at 120°C for 24 Hours, after rolling and punching, the electrode sheet was obtained; with the metal lithium sheet as the counter electrode and 1M LiPF6 EC:DEC:EMC solution as the electrolyte, a simulated battery was formed for elec...

Embodiment 2

[0028] x=0.1, the molecular formula is: Li 2 Zn 0.9 Cu 0.1 Ti 3 o 8 , the preparation process is as follows:

[0029] Weigh out 1 gram of H 2 Ti 3 o 7 , 0.287 g Li 2 CO 3 Put it into a beaker, add 20ml of absolute ethanol, mix well, weigh 0.767g of Zn(CH 3 COO) 2 2H 2 O and 0.078 g Cu(CH 3 COO) 2 ·H 2 O was added to the above solution, and the above solution was evaporated to dryness at 70°C with stirring, ground, placed in a muffle furnace, heated to 750°C at 3°C / min, and kept for 5 hours to obtain a Cu-doped lithium zinc titanate product .

[0030] Weigh 0.7 g of the product, mix it with acetylene black and PVDF in a mass ratio of 70:20:10, stir evenly, coat it on a copper foil, place it in a vacuum oven, and dry it under vacuum at 120°C for 24 Hours, after rolling and punching, the electrode sheet was obtained; with the metal lithium sheet as the counter electrode and 1M LiPF6 EC:DEC:EMC solution as the electrolyte, a simulated battery was formed for electro...

Embodiment 3

[0032] x=0.15, the molecular formula is: Li 2 Zn 0.85 Cu 0.15 Ti 3 o 8 , the preparation process is as follows:

[0033] Weigh out 1 gram of H 2 Ti 3 o 7 , 0.287 g Li 2 CO 3 Put it into a beaker, add 20ml of absolute ethanol, mix well, weigh 0.724g of Zn(CH 3 COO) 2 2H 2 O and 0.116 g Cu(CH 3 COO) 2 ·H 2 O was added to the above solution, and the above solution was evaporated to dryness at 70°C with stirring, ground, placed in a muffle furnace, heated to 750°C at 3°C / min, and kept for 5 hours to obtain a Cu-doped lithium zinc titanate product .

[0034] Weigh 0.7 g of the product, mix it with acetylene black and PVDF in a mass ratio of 70:20:10, stir evenly, coat it on a copper foil, place it in a vacuum oven, and dry it under vacuum at 120°C for 24 Hours, after rolling and punching, the electrode sheet is obtained; the metal lithium sheet is used as the counter electrode, and the EC: DEC: EMC (volume ratio = 1:1:1) solution of 1M LiPF6 is used as the electrolyte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com