Preparation method of multielement nanomaterials and solar cell electronic silver paste containing multielement nanomaterials

A technology of solar cells and nanomaterials, applied in the field of electronic silver paste for solar cells, to achieve the effects of excellent ohmic contact, increased silver content, and reduced series resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A method for preparing multi-component nanomaterials, the preparation method comprising the following steps: (1) adding the first metal organic matter and a surfactant into a high-temperature resistant organic solvent, and keeping the temperature for 30 -60min, the first metal organic compound decomposes to form the nanoparticles of the first metal oxide; (2) Then the second metal organic compound is added to the organic solvent, and the second metal organic compound decomposes at 300-500°C to form the first metal organic compound Two kinds of metal oxides, and the second metal oxide uses the first metal oxide as a seed, and grows into the second metal oxide nanoparticles next to the nanoparticles of the first metal oxide; (3) adding in sequence Contain the required metal-organic substances until the required multi-component nanomaterials are formed; (4) The multi-component nano-materials are separated from the organic solvent by a rotary centrifuge; (5) The separated mu...

Embodiment 1

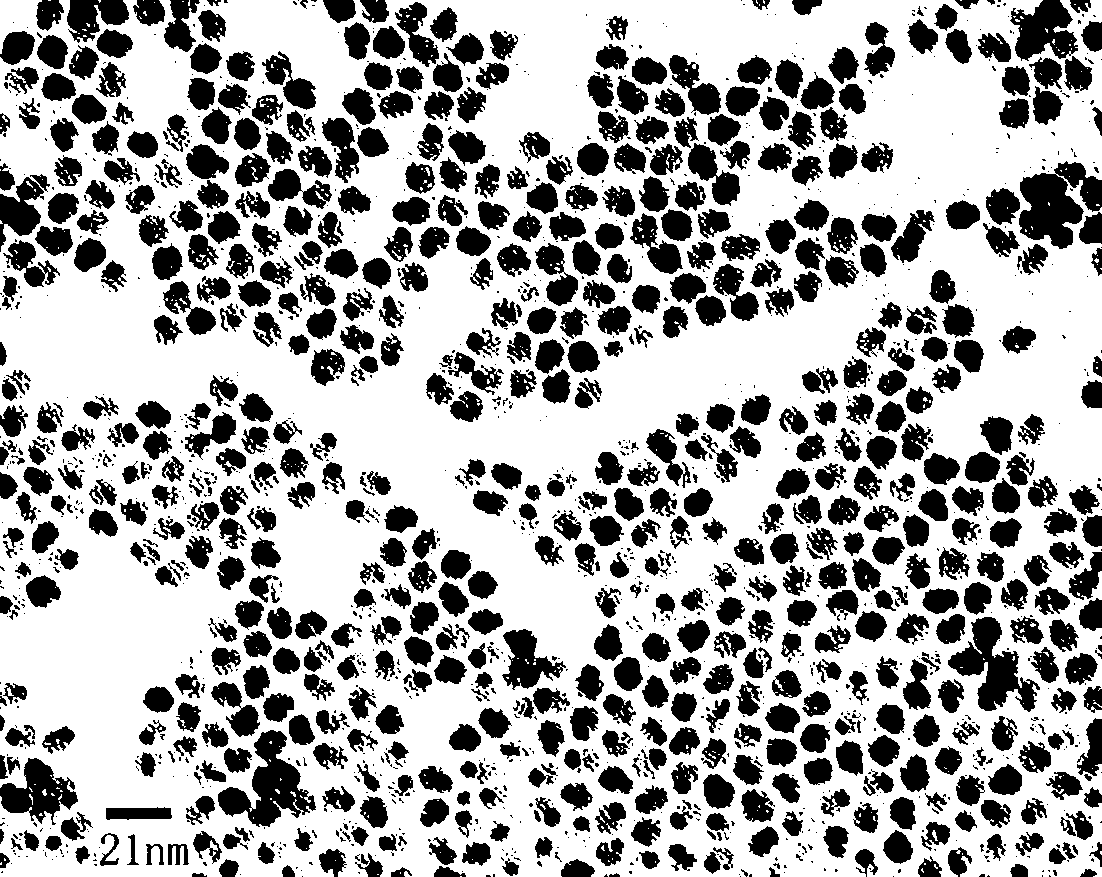

[0028] A Binary Nanomaterial PbO-SiO 2 The preparation method comprises the following steps: first, in phenyl ether, add lead acetylacetonate and surfactant, when the temperature rises to 380 DEG C, the lead acetylacetonate decomposes to form PbO nanoparticles when kept warm for 30 minutes; then Trichlorosilane is added to phenyl ether, and trichlorosilane decomposes at 450°C to form SiO 2 , and SiO 2 Seed PbO, grow SiO next to PbO nanoparticles 2 nanoparticles, which form the desired binary nanomaterial PbO-SiO 2 crude product; then the binary nanomaterial PbO-SiO 2 The crude product is separated from the organic solvent by a rotary centrifuge; the final separated binary nanomaterial PbO-SiO 2 After washing with alcohol and drying into powder, the binary nanomaterial PbO-SiO can be obtained 2 finished product, attached figure 1 Binary nanomaterial PbO-SiO 2 The TEM picture of the finished product; in the above preparation method, triethoxy (1-phenylvinyl) silane, 3-ami...

Embodiment 2

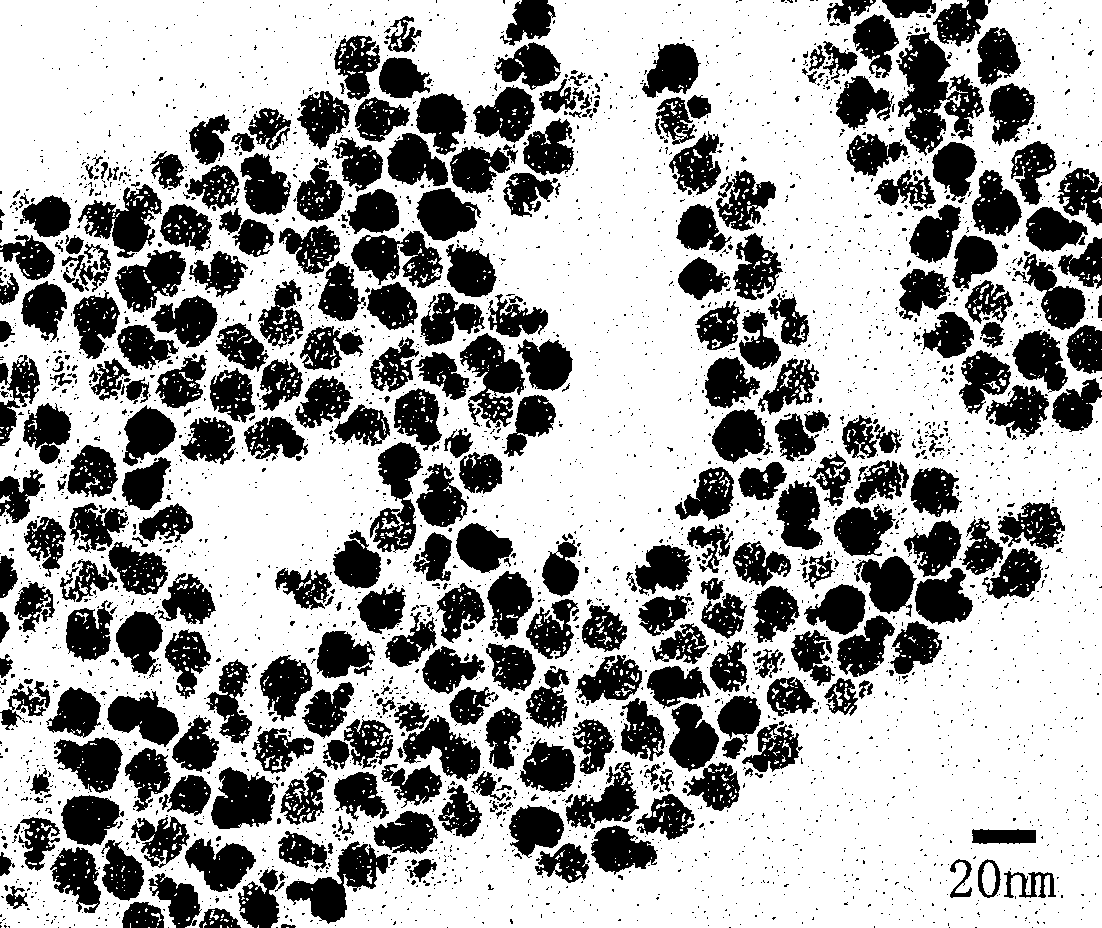

[0030] A ternary nanomaterial PbO-Al 2 o 3 -TeO 2 The preparation method comprises the following steps: firstly, adding lead acetate and a surfactant to 1-octadecene, and when the temperature rises to 400° C., the lead acetate decomposes to form PbO nanoparticles when kept warm for 50 minutes; then Aluminum acetylacetonate is added to an organic solvent, and aluminum acetylacetonate decomposes at 480°C to form Al 2 o 3 , and Al 2 o 3 With PbO as the seed, Al grows next to the nanoparticles of PbO 2 o 3nanoparticles; ammonium hexabromotellurate is then added to the organic solvent, and ammonium hexabromotellurate decomposes at 360°C to form TeO 2 , and TeO 2 with PbO-Al 2 o 3 For the seeds, the PbO-Al 2 o 3 The nanoparticles grow next to TeO 2 Nanoparticles; that is, the formation of the desired ternary nanomaterial PbO-Al 2 o 3 -TeO 2 crude product; then the ternary nanomaterial PbO-Al 2 o 3 -TeO 2 The crude product is separated from the organic solvent by a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com