High-alumina 316L stainless steel and preparation method thereof

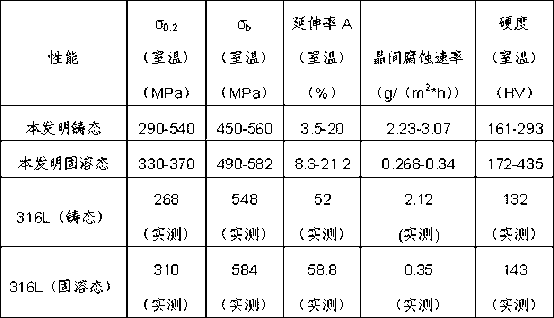

A technology of stainless steel and stainless steel plate, applied in the field of preparation of 316L stainless steel, can solve the problems of inhibiting the long-term use of stainless steel, deteriorating stability, etc., achieving good corrosion resistance and comprehensive mechanical properties, improving corrosion resistance, and easy passivation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Prepare materials and smelt according to the actual production of 316L castings. Furnace material is 316L stainless steel plate and industrial aluminum ingot, melted by medium frequency induction furnace, furan resin sand casting, molding sand ratio is quartz sand weight: resin weight: curing agent (p-toluenesulfonic acid) weight = 100: 1: 0.4, test block It is a standard Y-shaped test block. In order to enhance the compactness of the structure, a 20mm thick cold iron is embedded in the bottom of the sand mold.

[0017] According to the formula (mass percentage), Al: 1.5%, Cr: 16.745%, Ni: 13.79%, Mo: 1.97%, Mn: 1.97%, Si: 0.985%, C: 0.0295%, and the balance is Fe , Weigh the corresponding components, and calculate the burning loss of Al as 30%, a total of 15kg. The weighed alloys are loaded into the furnace in a certain order, and the heating system is heated up. Keep the temperature at about 700°C for 30 minutes, continue to heat to 1540°C, hold the temperature for ...

Embodiment 2

[0019] Prepare materials and smelt according to the actual production of 316L castings. Furnace material is 316L stainless steel plate and industrial aluminum ingot, melted by medium frequency induction furnace, furan resin sand casting, molding sand ratio is quartz sand weight: resin weight: curing agent (p-toluenesulfonic acid) weight = 100: 1: 0.4, test block It is a standard Y-shaped test block. In order to enhance the compactness of the structure, a 20mm thick cold iron is embedded in the bottom of the sand mold.

[0020] According to the formula (mass percentage), Al: 2.0%, Cr: 16.66%, Ni: 13.72%, Mo: 1.96%, Mn: 1.96%, Si: 0.98%, C: 0.0294%, and the balance is Fe , Weigh the corresponding components, and calculate the burning loss of Al as 30%, a total of 15kg. The weighed alloys are loaded into the furnace in a certain order, and the heating system is heated up. Keep the temperature at about 700°C for 30 minutes, continue to heat to 1540°C, hold the temperature for 20...

Embodiment 3

[0022] Prepare materials and smelt according to the actual production of 316L castings. Furnace material is 316L stainless steel plate and industrial aluminum ingot, melted by medium frequency induction furnace, furan resin sand casting, molding sand ratio is quartz sand weight: resin weight: curing agent (p-toluenesulfonic acid) weight = 100: 1: 0.4, test block It is a standard Y-shaped test block. In order to enhance the compactness of the structure, a 20mm thick cold iron is embedded in the bottom of the sand mold.

[0023] According to the formula (mass percentage content) in the experiment, Al: 3.0%, Cr: 16.49%, Ni: 13.58%, Mo: 1.94%, Mn: 1.94%, Si: 0.97%, C: 0.0291%, and the balance is Fe , Weigh the corresponding components, and calculate the burning loss of Al as 30%, a total of 15kg. The weighed alloys are loaded into the furnace in a certain order, and the heating system is heated up. Keep the temperature at about 700°C for 30 minutes, continue to heat to 1540°C, h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com