Halogen-free flame retardant thermoplastic polyolefin cable material

A thermoplastic polyolefin and cable material technology, applied in the field of polyolefin cable material, can solve the problems of the physical and mechanical properties of the cable material, the deterioration of the electrical properties, the processing performance, the inability to achieve the flame retardant grade, the large amount of smoke generated by the cable, etc., and achieve excellent physical and mechanical properties. Mechanical properties, easy for large-scale promotion and use, and the effect of low smoke generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

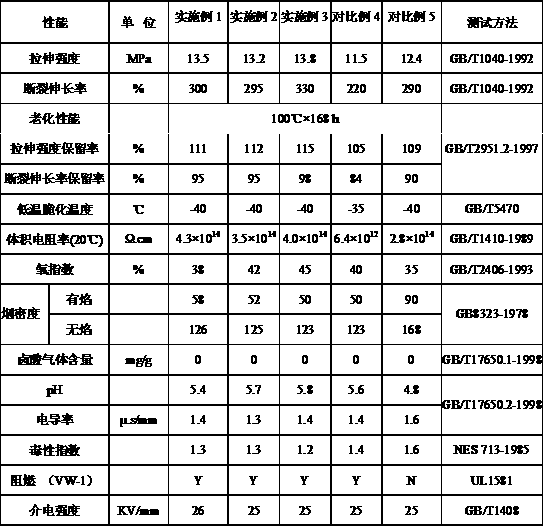

Examples

Embodiment 1

[0040] In this example, the compound flame retardant is made by mixing 60 parts of piperazine borate phosphate and 40 parts of melamine polyphosphate, wherein piperazine borate phosphate is surface-treated with 1% silane and has an average particle size of 3 μm. The average particle size of melamine phosphate is 5 μm.

[0041] The raw material composition of the halogen-free flame-retardant thermoplastic polyolefin cable material in this embodiment is shown in Table 1.

[0042] raw material name parts by weight raw material name parts by weight Linear Low Density Polyethylene 0 Zinc borate 4 Ethylene vinyl acetate 20 A silane coupling agent 1 Compound Flame Retardant 20 Dilauryl Thiodipropionate 0.5 Maleic anhydride grafted polyethylene 5 Zinc stearate 1

[0043] Table 1

[0044] The preparation method of this embodiment is,

[0045] (1) Prepare a compound flame retardant first, which is made by mixing 60 parts of piperaz...

Embodiment 2

[0050] In this example, the compound flame retardant is made by mixing melamine borate 75 and 25 parts of phosphate ester melamine salt, wherein piperazine phosphate borate is surface-treated with 1% silane and has an average particle size of 7 μm, polyphosphoric acid The average particle size of melamine is 15 μm.

[0051] The raw material composition of the halogen-free flame-retardant thermoplastic polyolefin cable material in this embodiment is shown in Table 2.

[0052] raw material name parts by weight raw material name parts by weight High-density polyethylene 20 Antimony trioxide 20 Ethylene methyl acrylate 50 Titanate coupling agent 2 Compound Flame Retardant 30 Dioctadecyl Thiodipropionate 2 Maleic anhydride grafted ethylene vinyl acetate 10 Ethylene bis stearamide 5

[0053] Table 2

[0054] The preparation method of the halogen-free flame-retardant thermoplastic polyolefin cable material in this example is the ...

Embodiment 3

[0056] In this example, the compound flame retardant is mixed by N, N-dimethyl-p-phenylenediamine borate 85 and 15 parts of neopentyl glycol phosphate melamine salt, wherein phosphate piperazine borate is 1% The amount of silane used for surface treatment and the average particle size is 15 μm, and the average particle size of melamine polyphosphate is 25 μm.

[0057] The raw material composition of the halogen-free flame-retardant thermoplastic polyolefin cable material in this embodiment is shown in Table 3.

[0058]

[0059] table 3

[0060] The preparation method of the halogen-free flame-retardant thermoplastic polyolefin cable material in this example is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com