Battery electrode or separator surface protective agent, battery electrode or separator protected by same, and battery having battery electrode or separator

A surface protective agent, battery electrode technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, battery pack components, etc., can solve the problems of many adhesives, reduced ionic conductivity, low mechanical strength, etc. High performance, excellent stress relaxation energy and low internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

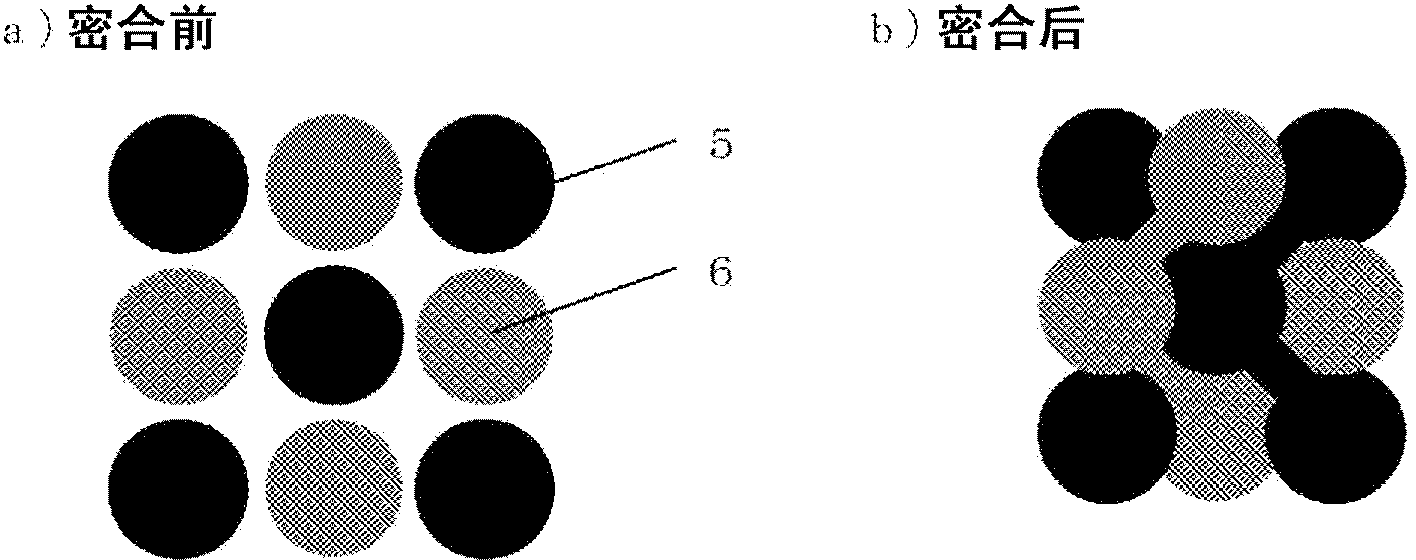

[0220] In Example 1, a method of manufacturing a lithium ion secondary battery using an electrode obtained by coating a battery electrode containing two types of organic particles or a separator surface protective agent composition on a negative electrode will be described.

[0221] (Manufacture of battery electrode or separator surface protective agent composition)

[0222] (Production of Fusion Bonded Organic Matter Particles 1)

[0223] Cyanoethylated pullulan (manufactured by Shin-Etsu Chemical Co., Ltd.: Cyanoresin CR-S, softening temperature = 90-110° C., hydrogen-bonding functional group value = 0.0005 mol / g or less) and pulverize to produce cyanoethylated pullulan particles with an average particle diameter of 3 μm.

[0224] (Preparation of Fusion Bonded Organic Particles 2)

[0225] Partially saponified polyvinyl alcohol (manufactured by KURARAY: PVA-205, value of hydrogen-bonding functional group = about 0.019 mol / g) was pulverized with a nano-jet mill (manufacture...

Embodiment 2

[0239] In Example 2, a method of manufacturing a lithium ion secondary battery using an electrode obtained by coating a battery electrode containing two types of organic particles or a separator surface protective agent composition on a negative electrode will be described.

[0240] (Manufacture of battery electrode protective agent composition)

[0241] (Production of Fusion Bonded Organic Matter Particles 1)

[0242] A 15% solution of N-methylpyrrolidone of polyvinylidene fluoride (manufactured by Kureha Co., Ltd.: Kureha KF Polymer#1120, softening temperature=160-180°C, hydrogen-bonding functional group value=0.0001mol / g or less) was spray-dried, Polyvinylidene fluoride particles having an average particle diameter of 3 μm were produced.

[0243] (Preparation of Fusion Bonded Organic Particles 2)

[0244] Made by the method of Example 1.

[0245] (mixture of two particles melt-bonded)

[0246] The powdery mixture was made by the method of Example 1 as a battery electrod...

Embodiment 3

[0258] In Example 3, a method of manufacturing a lithium ion secondary battery using an electrode obtained by coating a negative electrode with a battery electrode or a separator surface protective agent composition containing two types of organic particles and a solvent will be described.

[0259] (Production of Fusion Bonded Organic Matter Particles 1)

[0260] It was produced by the same method as Example 2.

[0261] (Preparation of Fusion Bonded Organic Particles 2)

[0262] It was produced by the method similar to Example 1.

[0263] (Fabrication of Compositions Containing Fusion Bonded Two Kinds of Particles)

[0264] Add 6000g of 2-methoxyethoxyethyl acetate, 700g of the above-mentioned organic particle 1, and 300g of organic particle 2 into a 10L beaker, and then stir evenly with a propeller mixer to obtain a liquid composition as a battery electrode or separator surface protection agent combination.

[0265] (production of positive electrode)

[0266] It was produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com