[0006] But the single-phase AC motor starter of aforementioned CN100581043C still has the following shortcoming: one, although both sides of the bottom of the positive temperature coefficient thermistor are contacted with the apex can significantly reduce the gap between the positive temperature coefficient thermistor and the housing. The supporting area in the cavity of the positive temperature coefficient thermistor can significantly reduce the volume of the positive temperature coefficient thermistor, for example, the weight is reduced from 35-40g to 15-16g, but due to the small size of the positive temperature coefficient thermistor The side edges in the circumferential direction (the applicant defines them as the front and rear side edges) still need to be in contact with the front and rear cavity walls of the positive temperature coefficient thermistor cavity in a large area, so it is not enough to reflect a more extreme energy-saving effect. The specific performance is The volume of the positive temperature coefficient thermistor is still too large, and the weight is still too heavy

Because the positive temperature coefficient thermistor reaches the

Curie point critical temperature of 140°C after starting, if the contact surface between it and the wall of the positive temperature coefficient thermistor cavity is large, the heat dissipation will increase, making the positive temperature coefficient

Thermistor power dissipation increases

Because the contact surface is large, the heat of the positive temperature coefficient thermistor is transferred by the shell, that is, the cavity of the positive temperature coefficient thermistor, resulting in heat loss

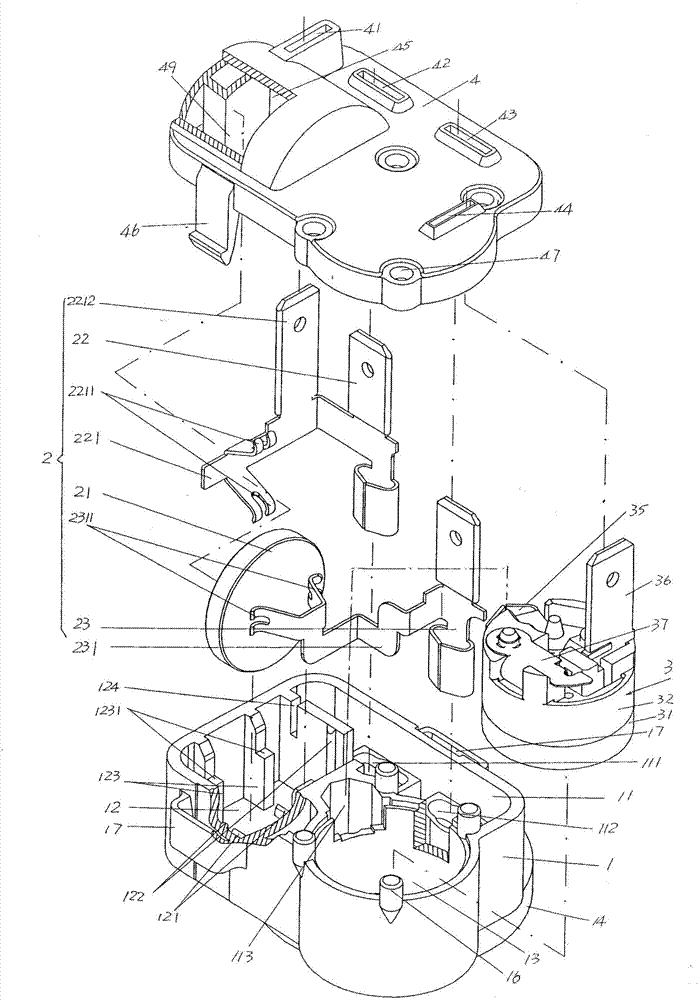

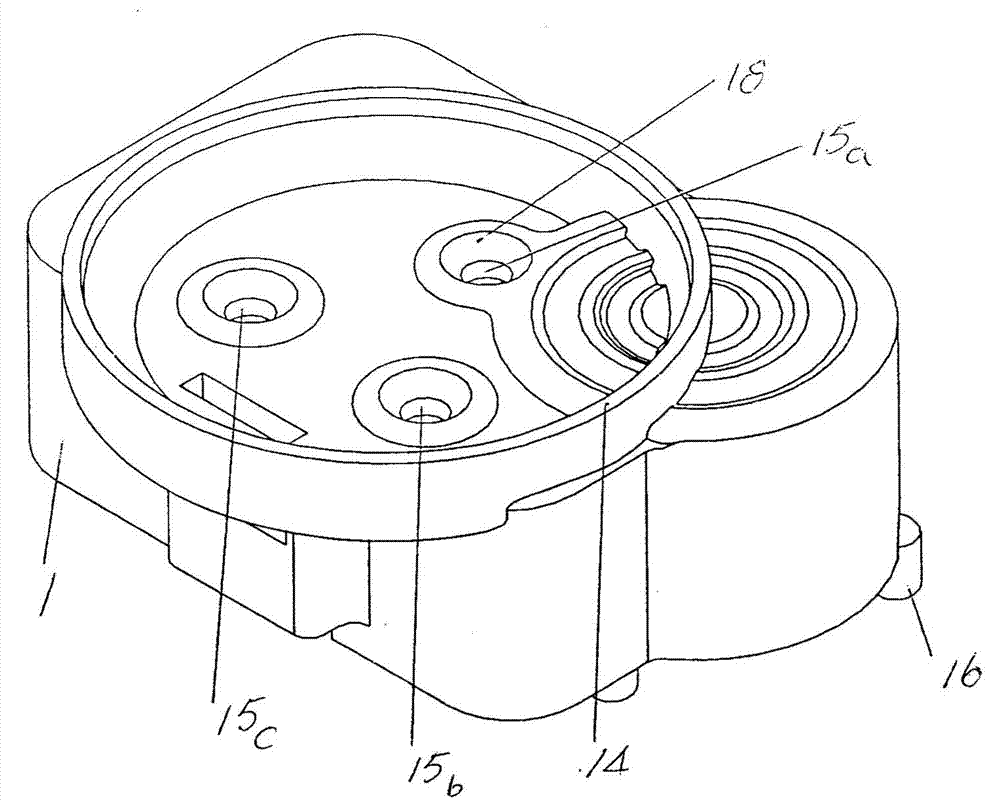

Theoretically speaking, forming a support wall on the front and rear cavity walls of the positive temperature coefficient thermistor cavity and forming a protrusion on the support wall can make up for the aforementioned deficiency and further reduce the volume of the positive temperature coefficient thermistor. The weight can be further reduced and the energy-saving effect can be reflected to the extreme degree, but repeated experiments by the applicant show that this idea is not advisable, because on the one hand, the aforementioned first and second pins and the positive temperature coefficient thermistor On the other hand, due to the excessive occupation of the space in the width direction of the positive temperature coefficient thermistor cavity, the installation of the starter is troublesome; secondly, because it is formed in the positive temperature coefficient thermistor cavity The structure of a pair of supporting walls at both ends of the device is relatively complicated, which leads to a relatively complicated mold for manufacturing the shell; third, since the top protrusion is formed on the

supporting wall, the bottom of the positive temperature coefficient thermistor, that is, the bottom surface, is in contact with the The distance between the cavity bottom of the positive temperature coefficient thermistor cavity is the sum of the height of the support wall and the height of the top protrusion, so the situation of excessively raising the positive temperature coefficient thermistor causes the positive temperature coefficient thermal The upper part of the sensitive

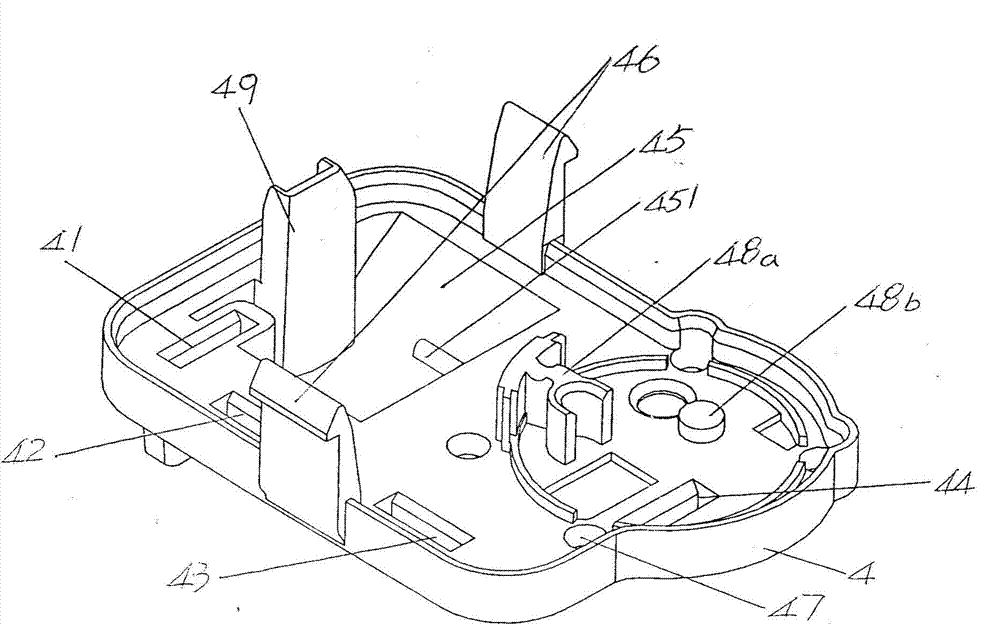

resistor protrudes from the cavity of the positive temperature coefficient thermistor, and the protruding part needs to be compensated by a sufficient raised cavity on the cover (the protruding part penetrates into the raised cavity). complexity, and significantly increase the depth (also called height) of the raised cavity of the shell cover, on the other hand, it increases the contact area between the positive temperature coefficient thermistor and the raised cavity, and on the other hand, in order to ensure the first, The second pin is in the middle position corresponding to the surface of both sides of the positive temperature coefficient thermistor to reliably hold the positive temperature coefficient thermistor and the position of the first and second pins must be moved upwards so that the first and second The

support point between the pin and the cavity wall of the positive temperature coefficient thermistor cavity (the part in contact with the support of the cavity wall) is moved to the upper cavity of the positive temperature coefficient thermistor cavity, thereby having a stable effect on the installation of the entire starter Influence, for example, the first and second pins are in danger of breaking free from the positive temperature coefficient thermistor cavity, which will cause the electrical contact between the first and second pins and the positive temperature coefficient thermistor to fail

Of course, by increasing the size of the housing in the height direction and thereby deepening the depth of the PTC thermistor cavity, the PTC thermistor can be located in the PTC thermistor cavity as a whole and can make up for the aforementioned disadvantages. Factors, but such a design will significantly increase the volume of the housing, that is, the problem of losing

sight of the other; Fourth, because the first pin is in contact with the first pin reed on one side of the positive temperature coefficient thermistor (the patent claims No. One spring piece) and the second pin reed (the patent is called the second spring piece) in which the second pin is in contact with the surface of the other side of the positive temperature coefficient thermistor are in a straight line with the positive temperature coefficient thermistor The surface of the positive temperature coefficient thermistor is in contact, that is, the first and second pin reeds are both horizontally parallel to each other and fully correspond to each other, so when the

electric spark is generated, the positive temperature coefficient thermistor will produce many cracks, because the opposite sides are still covered. The corresponding first and second pin reeds are elastically supported, and the cracked (cracked) part of the elastically supported positive temperature coefficient thermistor continues to be clamped in the original position stably, while the remaining fragments are scattered , so the power continues to pass through the elastically supported remnants of the PTC thermistor, causing these remnants and their associated first and second prong reeds to melt into each other, followed by a certain The result is an electrical

short circuit between the first and second pins, which in turn further accelerates the generation of abnormal heat, which is very likely to force further failures of the device, such as causing shell failure. Body

softening deformation, etc.

[0007] As far as the above-mentioned single-phase AC motor protector of CN100581043C is concerned, there are the following deficiencies: since the fixed seat only has a pin chamber for the spring piece and the pin (the patent is called the first pin) to accommodate it, when the spring piece and the pin are accommodated in After the pin cavity, the positioning effect of the fixing seat on the spring piece and the pin is fragile, so once there is a loose displacement, it will affect the electrical contact or disconnection between the moving contact on the spring piece and the static contact on the pin Effect

Second, since the heating wire cavity formed on the fixing seat is only for accommodating the heating wire, it has no limiting effect on the heating wire, and there will be arching in the

actual use process, which will affect the effect of the

bimetal sheet and its overall contact

Login to View More

Login to View More  Login to View More

Login to View More