Method of producing liquid crystal polyester

A technology of liquid crystal polyester and a manufacturing method, which is applied to liquid crystal materials, chemical instruments and methods, etc., can solve the problems of difficult continuous production and difficult discharge, and achieve the effect of inhibiting sintering and stable continuous preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

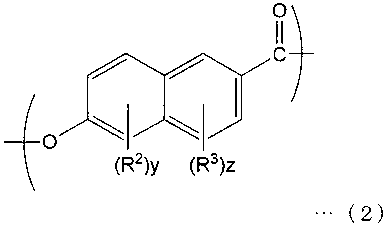

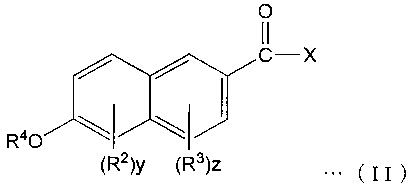

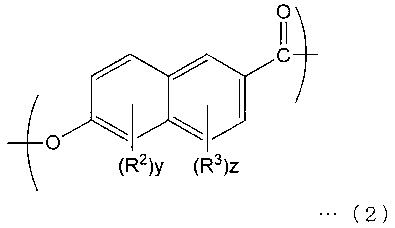

Method used

Image

Examples

Embodiment 1)

[0100] (1) Melt polymerization

[0101] As the polymerization tank, a three-way connecting pipe (ト-type connecting pipe) equipped with a ジムロロート cooling pipe, a nitrogen introduction pipe and a thermocouple for measuring the internal temperature, an anchor-type stirring blade, and a A 3-liter four-necked separable flask with a thermocouple on the outside of the flask. 1176.8g (8.52 moles) of 4-hydroxybenzoic acid, 654.9g (3.48 moles) of 6-hydroxy-2-naphthoic acid and 1347.6g (13.2 moles) of acetic anhydride were put into the polymerization tank. The external temperature of the flask was raised to 150° C. by a resistance heater, and the acetylation reaction was carried out under reflux for about 3 hours while stirring at 200 rpm. After the acetylation reaction was completed, the temperature was raised to 280° C. at a rate of 0.6° C. / min. During this period, the by-produced acetic acid in the polycondensation reaction was continuously distilled off. After reaching 280° C., stir...

Embodiment 2)

[0106] Prepolymer powder 2 was obtained in the same manner as in Example 1 except that the retention time at 280° C. during melt polymerization was 40 minutes. When the flow start temperature of the prepolymer powder 2 was measured, it was 228°C.

[0107] The obtained prepolymer powder 2 was subjected to solid-state polymerization in the same manner as in Example 1 to obtain a liquid crystal polyester 2 having a flow initiation temperature of 269°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com